In this episode, we’re going to be chatting about cannabis decontamination with Jill Ellsworth, founder of Willow Industries.

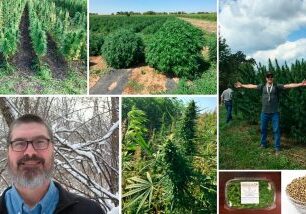

Our hosts for this episode are Reed Preston, founder of Preston Hemp Co, and Dana Mosman, co-founder of Triminator.

Transcript

Intro: Welcome to Own Your Harvest, powered by Triminator, global leader in cannabis harvesting equipment, we will be bringing new, valuable insights from the front lines of the cannabis industry, giving direct access to our award-winning team and educating you on a variety of topics. From field service to extraction, we have lined up some amazing guests for 2021 to kick off this new podcast. And now, here are your hosts Reed Preston, founder of Preston Hemp CO and Triminator ambassador and co-founder of Triminator, Dana Mosman.

Reed Preston: Welcome to the Own Your Harvest podcast. This is the 8th episode of our podcast series. I’m Reed Preston, founder of President Hemp Co, and an ambassador for Triminator. I’ll be hosting this series along with our Triminator co-founder, Dana Mosman. This episode, we’re going to be chatting about cannabis decontamination with Jill Ellsworth, founder of Willow Industries.

Dana Mosman: Thanks for the intro, Reed. Yeah, excited to have Jill on here. Obviously, what we do in the post-harvest space, we don’t touch it too much. But pests and mold remediation is super important, especially nationally as we get more and more formalized in the cannabis industry. So, excited to talk more with Jill about Willow and what they’re doing in that space. So, welcome to the podcast.

Jill Ellsworth: Hey, guys, thanks so much for having me. Excited to be here.

Dana Mosman: Absolutely.

Reed Preston: Yeah. Thanks for joining us today, Jill. So, yeah, let’s get right into it. Tell us exactly what Willow is and how you got into the cannabis industry.

Jill Ellsworth: So, Willow is the organic cannabis kill step. What that means is we get rid of microbial contamination on finished flowers. So, dried, cured, trim flower goes into our system, which is an ozone system, patented, proprietary ozone system that gets rid of any sort of contaminant on the flower being any sort of pathogen. So, mold, yeast, E. coli, salmonella, bacteria, ensuring that cultivators pass state testing, but most importantly, consumer safety, ensuring that consumers are safe when they partake in this type of product.

And then going to your question, “How did I get into this?” well, I’m a registered dietitian. I have a master’s in food science, and I come from the food and beverage industry. So, I owned a cold pressed juice company in Santa Barbara and in Denver and was subjected to really strict HACCP regulations through the FDA. But most importantly, I had to have a kill step with my juices. And so, as I was exiting that business, I started looking at cannabis. And this was 6 and a half years ago in Colorado and seeing that the State had just mandated total yeast and mold testing. And as I dug into the regulations, I saw that cultivators had to test for these pathogens, but there was no requirement that they went through a kill step. And that is the last process in the production cycle to ensure there are no remaining contaminants on that product. So, cannabis didn’t have that. And I had kind of this crazy harebrained idea to find a way to clean cannabis. And that’s what we’ve done here at Willow.

Dana Mosman: Awesome. So, let me throw in a question there. In food and beverage, it sounds like that’s pretty standardized in terms of the kill step. Is that just universal no matter if you’re doing juice, or tomatoes, or apples, or is it specific to a type?

Jill Ellsworth: It is standardized, and it is required for all food producers. So, the type of kill step method really depends on the product that you’re producing. So, for instance, on juices, we used high pressure, which ensure that you got rid of the pathogens, but you didn’t destroy all the wonderful vitamins and nutrients in the juices. A lot of beverages go through heat pasteurization. Milk goes through heat pasteurization. There’s products that go through flash pasteurization. And then other products go through chemical washes. And so, every single consumer good has a kill step. And that’s why, at the time, I was so surprised it wasn’t required in cannabis. And I was determined to find a way to bring that type of regulation, but technology to cannabis.

Dana Mosman: Do you think as more and more facilities go towards GMP as an example, do you think that becomes a more standardized part of the process, just in your opinion? Or do you think it takes like a regulatory move to make it a standard across the nation?

Jill Ellsworth: Well, what’s really interesting and what we’re seeing is that cultivators are preventatively implementing this type of technology, even before they’re moving towards GMP. Because once you are at GMP, you should have already had done this. And so, when federal regulation comes in, this will definitely be handed down and it will be quick and swift. So, thinking about this stuff ahead of time is of utmost importance.

But it’s really interesting. I imagine you guys have seen this in your career. No one wants to talk about this stuff 6 and a half years ago, 7 years ago. And like, “No, no, no, we’ve forever.” It never does. But like as we scale and grow, become a legitimate industry, these things really matter. And so, I’m excited to start to see that pivot towards like being legit and having these processes.

Dana Mosman: Yeah. Well, everyone just so happy about it being legal that we forgot about the rest of the stuff.

Jill Ellsworth: Yeah, I know.

Reed Preston: Yeah. It’s definitely important to the consumers. I’d almost, from what it sounds like, I’d compare it to like seeing an organic label at a grocery store in your produce section. Like do you have anything aside from Willow and the technology, like are you pushing for any labels like some sort of kill step label or anything like that?

Jill Ellsworth: Well, that’s really interesting that you ask, because what we’re seeing are some States are starting to contemplate whether or not to require cultivators to disclose what type of technology they use for decontamination or kill step. The State that’s the furthest along is Nevada. And they’re going to start requiring cultivators to disclose on the label, what type of method they use. And there’s a list of methods that are approved. And you pick and choose the one that you’ve employed in your cultivation.

I think for the industry, it’s a bit of a scare, because it’s like, “Oh, my gosh, we actually have to be very transparent about our practices.” But on the flip side, like this is what we should be doing for consumers. Consumers should have, should be able to make an educated choice. Just like you said, you go to the grocery store, do you want organic? Do you want non-organic? Well, you get to make that distinction and you get to make that choice. Well, you should also have that choice with cannabis. But until labels are required, no one’s really out there saying they’re doing this, but it will come. It’ll happen.

Dana Mosman: Do you think that…? Yeah, go ahead, Reed.

Reed Preston: I was going to say, the only other kill step I know of right now is like hydrogen peroxide dunks. I just want to throw that out there. I don’t want that label.

Jill Ellsworth: Well, that’s the thing. Once this happens, I mean, I think cultivators, we’re going to gravitate towards the technology that’s tried and true. Us, Willow, being one of them. So, I think you’ll see less of hydrogen peroxide dunks because you better believe like that cultivator is not about to put that on the label. So, I think that will become a thing of the past.

Dana Mosman: Do you think the consumer…? I mean, the consumers are the lab tests and the requirements State by State are all over the board, right? But do you think the consumer has enough knowledge to not just think about the lab tests? Like, do you think that knowing how the pathogens are killed, for example, matters to them? Or do you think it’s more like it should be a national testing standard that there’s whatever percent of pathogens are allowable or not allowable? How do you feel about that?

Jill Ellsworth: Well, so that’s definitely a very contentious topic. And what I’m seeing across the country, I just spoke at a panel and in Michigan about labeling for decontamination methods. And I think that concern there is like, “Well, are we just going to scare consumers?” First of all, they don’t know, a lot of them don’t know that cannabis is tested. And why is it tested? So, I think there needs to be a ton of education. But oh my gosh, I would love to see a standard testing program rolled out across the country. I mean, it is a patchwork of regulations. That’s really hard for MSOs to bifurcate what’s happening in each of their States. But also, there’s just no consistency. There’s no consistency in lab testing. And so, one, we need to educate consumers, and two, the industry needs to do a better job at laying out more consistent testing protocols across the country.

Reed Preston: Yeah, definitely. I’m in the hemp space and it’s actually become more consumer regulated than anything. Like, if you go on Reddit and look up ‘hemp flowers’ or anything, there’s everyone just reviewing what companies are actually following standards and have full panel testing and all that available, because it’s just not regulated right now. And I mean, technically you don’t need it. All you need is a potency test no one’s worried about heavy metals or anything else in their flower. But getting back to Willow like, what’s the…? I know you mentioned ozone. Like, can you explain kind of what that is to our listeners, and how Willow uses it?

Jill Ellsworth: Yeah, absolutely. So, ozone is an incredible oxidant. And it’s a very hard gas to harness. It oxidizes back into oxygen as quickly as it’s produced. And so, what we’ve done at Willow, we’ve really perfected how to harness ozone and use it to treat cannabis. Over the years, I’ve seen many, many companies come and go trying to use ozone. I’ve also talked to countless cultivators saying they’re using ozone in their own way. But it typically never works.

And so, what we’ve done at Willow is we found a way to you, harness ozone, produce ozone, handle that and maintain the concentration of ozone within our system, and for the desired treatment time without disrupting terpenes, cannabinoids, the color, the structure of the flower, but then also killing pathogens. So, there’s a ton of different variables that we have to take into consideration.

One thing that our machine does is it pulls in ambient oxygen. It concentrates that oxygen. And then through an electrical charge, it produces ozone. So, then ozone floods a drum. We hold it at the desired concentration that we have researched and tested millions of times over. And it holds it at that concentration for the treatment time. Treatment times can range between 1 to 6 hours, depending on how contaminated the flower is. And then once that done, the ozone is pulled out of the drum and converted right back to oxygen. So, there’s no off gassing, it’s a really safe system. And ozone can be very dangerous. You can’t breathe it. You can’t be around it for long periods of time. So, our system has a triple layer safety method to it and make sure that all operators are protected.

Reed Preston: Awesome. I know you said takes anywhere from one to 6 hours. How much product is that with? Do you have like different size machines right now? Or is it all kind of 1 size? Like how much?

Jill Ellsworth: So, in our Willow Pure 360, we can treat between 10 and 20 pounds per run. And that’s a… that variables dependent on bud size, density. So, if you’re treating say 15 pounds, and you know the threshold of contamination, I mean, it can, again, take 1 to 6 hours. But typically, if a cultivator is using this as a true kill step, they are around the 1 to 2-hour run. So, once it goes through that entire post-harvest cycle, right before testing, they put it in the Willow, they treat it, then it goes to testing and then packaging.

Dana Mosman: How do you know you said something like when it reaches a certain threshold? So, how do you know the threshold going in and coming out? Like what are they using labs? How does the operator do that?

Jill Ellsworth: What we do is we really try to empower our cultivators to understand contamination right when it’s coming out of postharvest. So, we recommend triplicate samples going to the lab before it’s treated in our system. So, we get a baseline. And then once we really understand the baseline of the cultivator, then we can make recommendations based on thousands of data points of historical data that we’ve collected over time.

So, if we are in a State like Colorado and the threshold is 10,000 colony-forming units of total yeast and mold, and they’re in the let’s say, 20 to 30,000 range, which is just a little over a threshold, we typically will recommend 1 to 2 hours. But I’m sure you guys have seen this, lots of dirty, dirty weed. We’ll see cultivators in the millions of CFUs. And so, that typically takes a lot longer to treat. Because then you run into endophytic contamination, which is not something that Willow treats.

Dana Mosman: And in layman’s terms, what does that mean?

Jill Ellsworth: Yeah. So, it means contamination that grew within the plant over the plant’s lifecycle. And a lot of that contamination we see comes from mothers. It comes from the way the plant is cut. It comes from water sources, nutrients, the soil. All of those different inputs of the plant’s life cycle from the very beginning can attribute to endophytic contamination. So, then by the time it gets to Willow, we’re seeing extremely high contamination levels, that’s actually it’s in the veins and the vasculature of the plant. And so, that’s typically something that we will say, “This is not something we can treat. We would recommend extracting or not even selling that type of product.”

Dana Mosman: Gotcha. Okay. That’s interesting. So, basically, if the contamination happens, and isn’t from day 1, or day 3 or early on in the growth cycle, then then you can treat it?

Jill Ellsworth: Yeah. What ozone can do is treat surface-level contamination. I mean, it’s a great surface-level oxidant. And so, if it’s on the surface, and there’s a lot that can… how that can happen too. A trimmer touching it in the wrong way, if it’s actually human, or even going through the cure process. We can definitely get rid of it.

Dana Mosman: How does that work? I was reading a little bit about ozone beforehand, and one of the comparisons was against like chlorine basically in produce. They were talking about surface level. And so, their example is a tomato. And so, I’ll use the same example. To me, a tomato has like a very hard skin, exterior skin. It seems like it could be treated with chlorine relatively easily. It has like a very obvious surface. But cannabis doesn’t have a very obvious surface to me, although maybe at a molecular level, it is. But like, when you get inside a bud, is that surface contamination, or is that internal?

Jill Ellsworth: Typically, that’s internal.

Dana Mosman: Okay.

Jill Ellsworth: Like, if you break open the bud and you see bud rot, that would be endophytic contamination.

Dana Mosman: Okay.

Jill Ellsworth: A lot of surface-level contamination, you can’t see. Microbes are floating through the air all the time. Microbes everywhere. And so, but they’re kind of these big, bad things, and you can’t see that can cause you to fail a test.

Dana Mosman: Right, right. But anything within structure of like, within the bud structure that you might commonly understand as a contaminant is maybe outside of what the ozone technology can do at this point?

Jill Ellsworth: Correct.

Dana Mosman: Yeah. Okay.

Jill Ellsworth: And we’re doing a ton of innovating here at Willow. I mean, that’s one of our core tenants is to continue to at all time. And so, we’re doing some really cool R&D right now to find ways to like, how can we actually penetrate into the bud? And like what does that look like?

Dana Mosman: Right. And how does it…? Does it work on Trim? Trim has a high value now. I mean, I guess a lot of it goes to extract, so maybe it doesn’t matter. But do you have people using it for Trim?

Jill Ellsworth: We do. Yeah, we do we have people using it. I mean, predominantly is flower. But a lot of cultivators, like you said, are selling the trend, is it going into a pre-roll? So, we definitely have quite a few customers treating their trim as well.

Dana Mosman: Right. Makes sense. And how about this, like treating elements? In the food and beverage space, it seems like it’s used a lot to like treat like tools of the trade. Are you using it all for that just for like scissors? I mean, scissors really easy. I don’t know. But it seemed like that surface treatment is, again, kind of what it’s used for in other industries. Are you seeing farmers use it for that?

Jill Ellsworth: We always recommend best practices, and some of those are using our systems to decontaminate some of these tools. But we can only make so many suggestions. I’m a big ozone believer, because it’s also used therapeutically, which I do a lot of research on. But I just want them to clean their flower.

Dana Mosman: I think all consumers do, whether they say it or not.

Jill Ellsworth: Right, right.

Reed Preston: Yeah. I saw something that said that Willow extends the shelf life of flower. Can you speak on that a little bit, how that works?

Jill Ellsworth: Absolutely. We started doing studies years ago on the extension of shelf life. Because one thing we saw is that flower stayed fresher longer when microbes were removed. Because I mean, listen, if you compare this to produce, you see a strawberry, it has mold on it. Well, that strawberry is going to continue to degrade very quickly as the mold continues to multiply, and so what we saw we did this really great study is that we did a 0, 30, 60, 90-day study with the same flower over time with a third party lab here in Colorado and showed that there was almost no microbial growth after being treated in the Willow at Day 0 compared to the control sample.

And that just shows us that getting rid of those contamination points will help the flower continue to stay fresher longer. But then also, you’re just not seeing that degradation. You’re not seeing degradation of terpenes, or cannabinoids as that flower sits on the shelf. So, I’d happily send you the study. It was really interesting to see. And I think what we’re going to see down the road, and New Jersey actually implemented this regulation is they’re actually testing for shelf-life stability. And so, they’re requiring cultivators to save samples of every single batch, and they’re going to come back and test it at, I think it’s 90 days, I think it like goes into years, that they’re going to require cultivators to continue to hold on to samples so they can determine, what is the stability of this? Because they do that in food. They do that in beverage. Like, they know how long that juice can sit on the shelf before it’s not consumable. We should know that about cannabis as well.

Reed Preston: Yeah, absolutely. I mean, it’s in terms of purchasing too.

Jill Ellsworth: Absolutely.

Reed Preston: So, there’s been some industry discourse surrounding the safety of ozone, which you guys support. Can you tell us a little bit about that?

Jill Ellsworth: Yeah, absolutely. There was an interesting article that came out about warning consumers, cultivators, whoever, about the dangers of ozone. And I think, first and foremost, it was a competitor trying to get a little leg up in the industry. But it also was not factual. There was no data that came along with it. And I think it just caused a lot of unnecessary concern in the industry. Instead of actually digging into the science of ozone and how it’s used in different applications, it was kind of this blanket statement, like, “Oh, my God, ozone is terrible. Stay far, far away from it.” But it didn’t actually go into the science of research, like how ozone oxidizes certain qualities of a product.

And so, I didn’t like to see that because it’s false information. And there was no data to back it up. And listen, if you’re going to put out an article like that, you better have data, and you better have studies. And there were none to go along with it. So, just move on and put out sound research.

Dana Mosman: There you go. You did mention, and I did come across this too in my every consumers Google search, is like the safety of ozone. And you mentioned it’s your system is safer for operators. You mentioned multiple chambers. And so, like, if someone is just…? What are those steps to make it safe that you guys are undertaking?

Jill Ellsworth: Well, we spent a lot of time on ensuring that the system is safe, specifically to what you said, Dana, I mean, ozone is dangerous. You cannot breathe ozone. So, we have this 3-prong safety system in our Willow pier unit. So, 1, ozone floods into the drum, there’s sensors in there. Now, if ozone gets out of that drum, it’s contained in an entire structure that would not allow ozone to leave that. And there are systems and sensors in there to alert our mechanics and our electronics that, if ozone were to sneak out of that, everything shuts down, so it no longer produces ozone. And then we have sensors in our back cabinet, where all of our electronics and mechanics are that also can detect if there’s any bit of ozone that have like snuck out because it’s a little gas, like it can get anywhere.

So, everything will shut down immediately. The system will alert Willow what’s happening, and then we take immediate steps to troubleshoot and ensure that that system is back up and running appropriately. We also have external ozone sensors that all of our customers get. And so, if by chance, a little bit of ozone comes out of the system, that monitor obviously activates, and so we take immediate precaution. But we spent a lot of time ensuring that this is safe for any operator. I mean, we’re working in an industry where I think it needs to be very plug and play, as you guys know.

Dana Mosman: Yeah.

Jill Ellsworth: Dealing with clients and machinery and big systems. And so, I know you guys really understand the necessity of like safety.

Dana Mosman: Absolutely, absolutely. What for you guys, as the industry matures, and as we’re seeing kind of an evolution. For Triminator, we have everyone from like a very small home grower all the way up to the most kind of institutional, large scale growers as well. For you guys, where do you see the ideal customer for you? Or like, what is the ideal use case for someone looking at the Willow technology? You’re like, “Oh, that fits the box. They should talk to us.” Who is that? Is it farmers? Is it distributors? Who is it?

Jill Ellsworth: Well, Dana, that’s a great question. So, we really work with a variety of cultivators, like yourself. We don’t work with home growers. Our systems aren’t small enough and compact enough to get into that home grow just yet. But we work with single State operators and multi state operators all across the country. We’re also in Australia. And so, we can work with anybody. But it really boils down to finding the right partners for Willow that care about their holistic approach to clean cannabis.

We want cultivators that aren’t looking to cover up bad growing practices. We want cultivators that really understand how important it is to grow clean, compliant cannabis. And that’s definitely not everybody. I mean, I’ve worked with many cultivators in the past that are like, “I don’t care about anything that you’re saying, I just need to make sure my flower passes testing.” Well, that ideal and that thought process is a thing of the past. I mean, that can’t be like how this industry evolves. So, we really look to partners that have the same ethos as us that have, the same vision and mission of the cannabis now, but cannabis in like 10, 15, 20 years, like, what is this industry going to look like? And how is it going to scale so that like, we stay around for hundreds and hundreds of years, that we can evolve like food and beverage did?

Reed Preston: What steps do you recommend like your customers from start to finish to get clean cannabis product or clean cannabis flower?

Jill Ellsworth: That is a great question for my microbiology team. One thing that we do for all of our partners when they sign on to a lease of our Willow Pure system, our microbiology team that’s led by our Director of Science, who has a PhD in microbiology, they come into your cultivation, and they do an entire really in-depth microbial assessment. Because the most important thing is understanding where does microbes come from? Like, where are they coming from in your grow? We can know it’s coming from water, all the things I discussed before, but actually, where’s it coming in your grow? And what are you not thinking about? What are some of the critical control points that you haven’t identified that we can help you identify?

Because if we help you implement best practices, GMP, HACCP, critical control points, and really understanding your production cycle and supply chain, you’re going to have a much easier time with our system, with passing State testing, and with putting out high-quality, clean product. And so, we really dig into that with all of our partners in the beginning. And I think that’s the most value that we bring.

In addition to our technology, it’s great, but like the value we bring is really understanding and being experts in microbes, and where are they coming from? So, I think that we identify what’s happening and how you can kind of move towards and implement best practices.

Dana Mosman: Mm-hmm. How much does the environment matter? Like I know, in Denver, you’ve been in these facilities, I’ve been in them, they’re like, the least all the worst warehouse space that grows early on. It was like something nasty, and then it became a grow. How much does that matter, versus the like sparkling, clean, Israeli facility or whatever? Does it impacted? Or is it all the inputs on the plant? How does it break down?

Jill Ellsworth: That’s a great question too. It’s kind of a little bit of both. So, some of these legacy warehouses, I mean, they’re just awful. But also, they really haven’t been maintained. And I think that’s the bigger issue. Yeah, cultivators moved into these warehouses that were used to make tires or whatever. But what wasn’t looked at from the beginning was how can we maintain a clean facility? How can we ensure that we don’t have black mold growing on the walls? How can we ensure that all of our workers and employees are wearing all the PPE we can give them, and ensuring they like implementing these clean practices?

So, the historical growth of that, I think, is an issue. But if we look at these $2 million facilities, the first 6 months, everything’s amazing. And then they start failing testing. And then the contamination starts to grow. And then it multiplies. And then soon, you have this out-of-control problem. And so, it’s really important to implement these procedures and these policies very quickly, and stay… I mean, you have to stay tried and true to that.

Dana Mosman: Yeah, absolutely.

Jill Ellsworth: Like I should not be a dog in your grow.

Dana Mosman: Well, there are plenty of them. Yeah, yeah. How do you guys… how have you seen the kind of international market shaping up? I mean, we see a big difference in how Europe, for example, perceives the marijuana industry, or cannabis industry, I guess, for Europe. But have you seen more interest in the product, a better understanding of it? Or how do they look at what you’re doing?

Jill Ellsworth: I think that they are subjected to much stricter regulations, especially if they are exporting. With our customer in Australia, I mean, they are essentially subjected to the EU GMP. So, they can export to Europe. And so, they are required to have super, super low contamination testing. I think it’s like 100s CFUs a mold, which Colorado growers throw their hands up in the air.

So, I think they’ve really taken GMP, HACCP standards, very, very seriously from the beginning, and implemented all of this upfront, rather than on the back end, which we’ve seen a lot historically in the States. Like our Australian customer, I mean, they brought in 3 Willow Pure systems immediately, before they’re even producing flower. Because they knew if we don’t irradiate this flower, which they wanted to avoid, we need to have another technology to ensure that we’re always going to pass. So, I think it’s a lot of forward thinking. Isn’t that your experience? Or has that been your experience?

Dana Mosman: Yeah, for sure. I mean, they seem like they’ve looked at all the different models, I guess. But they’re also way more conservative from like a health and safety perspective than the US is. Like if across the board, there were much more like just do it, and then wait and see if there’s problems. And then we’ll like put in some regulation to catch them. And they’re much more like, what could the problems be, and like put in all the safety checks early, which, honestly, there’s pros and cons to both methods. You have a ton of cost and some unnecessary regulation and all that stuff. But from the perspective of them being much more organized and thoughtful about their setups, I think they are ahead of us there. But they need to know a lot more. Their markets are still maturing too, are just getting started. So, time will tell how it takes off.

Jill Ellsworth: Yeah, yeah.

Reed Preston: You have another question there, Dana?

Dana Mosman: Oh, well, I guess from all your time, your history in the food space, and obviously, you’re well aware of the cannabis space. But if a grower is kind of looking at this decontamination or remediation steps, what technologies are they evaluating?

Jill Ellsworth: What’s been interesting is that we’ve seen different types of technology come and go. I kind of touched on that earlier. What has remained and continues to be utilized throughout the industry is, of course, ozone. But we also see a radiation being used throughout the United States. And of course, that’s used in some of these bigger countries. Like, Canada does require a radiation. It’s interesting to see what Latin America is doing, Europe, a lot of these countries that are exporting are required to irradiate. So, we’re seeing that. And then also, radiofrequency. We’ve seen that used here in the US. And then also, vaporized hydrogen peroxide.

So, kind of, Reed, kind of back to what you said earlier, it’s a little different than dunking it, but that is also used. I’ve heard that being used. So, I think my recommendation as a cultivator is to look at all the options out there, and definitely dig into what’s the mission of a company? What’s their goal? But also, do have similar goals and missions? Because I think if you line up with the technology that you’re working with, I think that really, I think it really lends to how you want to be perceived in the marketplace, especially when labeling is required.

Reed Preston: Mm hmm. Yeah. I was going to ask like what you’re looking forward to in the industry both in the US and internationally? Like, what are some of the things that you’re looking forward to in the coming years with more regulation coming in and different States legalizing, and maybe the whole US legalizing, Europe? Yeah, what are you looking forward to?

Jill Ellsworth: Well, I mean, I would be excited to see federal legalization, but I still think we are so far away from that. In terms of States legalizing I mean, New York and New Jersey, really exciting to see what’s happening there. But also, how they’re contemplating their regulations and what they see as important, and how different that is across the country. So, I we certainly, at Willow, we don’t like push regulation, but I think it’s inevitable. And I think what we try to do is educate our customers, educate the industry, and most importantly, champion for that consumer. Because we all want to be in the know and be educated and to get transparent information from producers. I mean, I certainly look for that in Colorado. And I know too much. So. It’s always like that. You’re like, “Oh, my God, I can’t go there. I know too much.”

Dana Mosman: You don’t know what’s in your groceries, but you know a lot about cannabis.

Jill Ellsworth: No, no. So, I’m just excited to see the evolution. I mean, being in this for as long as I have then, it’s like no one cared at all in the beginning, and people care now. And I attribute that to a lot of the hard work we’re doing but a lot of the hard work everyone is doing, so I’m just excited to, 1, still be here.

Reed Preston: Yeah.

Dana Mosman: Well, they’re come and go in this industry. Yeah.

Jill Ellsworth: Like me the other day. Like, I saw him at a networking event. They’re like, “I had no idea you’re still in the industry.” I was like, great. But that is what’s true. So, you know what? Just keep on keeping on. It’s a hard industry.

Dana Mosman: Yeah, it’s true. Like all that. I mean, early on, everyone was so excited about it. I mean, people are still super excited about it. But it kind of gets buried. Like, I remember early trade shows, I would do like I went to Canna Con in Washington. Oh, my gosh, the number of companies that were in Canna Con in Washington, in I don’t even know the year. And the number, like if you had a reunion now, there would only be like a handful of us. So many people excited about it, and then not so many make it in the end.

And the same with the growers and the producers too. And so, I think the more we can educate them, especially in new States, like, “Hey, that’s a hard road. This is some of the stuff that you need to be aware of.” And it’s not as easy as just throwing some plants in the ground and putting up a retail shop. There’s so many nuances to it, as you know and we know. So, yeah. Thanks for the education today, I appreciate it.

Jill Ellsworth: Yeah, thank you for having me on. And thanks for the good questions. You never know.

Dana Mosman: Yeah, yeah. Well, we do our best. So, yeah, thanks again.

Dana Mosman: I’ve been Googling before. If people want to get a hold of you or find out more, how do they do that, Jill?

Jill Ellsworth: They can go to our website, willowindustries.com. I’m on LinkedIn, active on that. Always reach out to me. I am an open book, and happy to talk about contamination until I’m blue in the face. Most people don’t want to. I get it. But we’re here. We’re here to support the industry. And that has been our goal from the very beginning. We just want to continue to help this industry move towards more legitimacy and scale the way we all know it’s possible.

Dana Mosman: Absolutely.

Reed Preston: Awesome. Yeah. Thank you, Jill. So, make sure to join us for upcoming episodes. We’ve got some exciting guests lined up, including one of our brand ambassadors, Rakkems. Rakkems does some amazing work in the solventless field, and he’s well known for his mechanical separation of THCA. I’m looking forward to getting into that. And yeah, thanks so much for listening to the Own Your Harvest podcast powered by Triminator. If you’ve enjoyed this podcast, please subscribe to the show and share with your fellow growers and farmers.