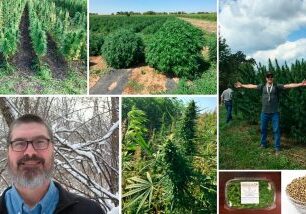

In this episode we chat with Noelle Joy, who’s working on her PhD in horticulture at the University of Georgia. She talks with us about traditional drying methods for a few different medicinal herbs, including hemp, and describes what it’s like farming in Georgia.

Our hosts for this episode are Reed Preston, founder of Preston Hemp Co and Dana Mosman, co-founder of Triminator.

Transcript

Reed Preston: Welcome to the Own Your Harvest podcast. This is our second episode of our newly launched podcast series. I’m Reed Preston, the founder of Preston Hemp Co and an ambassador for Triminator. I’ll be hosting the series along with our Triminator co-founder Dana Mosman.

This episode, we’re going to be chatting with Noelle Joy, who is working on her Ph.D. in horticulture at the University of Georgia. She’s been studying traditional drying methods for many different medicinal herbs, including hemp.

I’m excited to get it in this podcast because I personally worked at one of the first hemp drying facilities in Oregon and drying is such a crucial process.

Dana Mosman: Yeah, thanks, Reed. And yeah, I’m excited to have Noelle on here as well. So, Noelle and I have gone back a little bit now. We both got introduced by Dr. Alison Justice, who recognized Triminator has been working on a drying study at the University of Arkansas for a while. And then I was speaking to Alison about that and she said, “Hey, I’m sitting on an advisory board for someone at the University of Georgia.” And so she made the introduction between Noelle and our team at the University of Arkansas.

It’s been really great to sort of see that cross-collaboration. We just originally wanted to go out to make sure we weren’t duplicating the studies because I haven’t seen any hemp drying studies really. I’m sure there’s maybe a few out there now, but at the time there were none. And I was like, oh man, I hope we’re not duplicating here.

And then I also don’t know a ton about academia and how that works – if it’s competitive or collaborative or whatever. So it’s been great to see it’s collaborative. And Noelle has been a great help in terms of, uh, helping us scope our study. And hopefully, we’ve been helpful to her as well. So excited to talk about drying today and Noelle’s study, and excited about the whole thing.

Reed Preston: Yeah, me too. And I know you spoke briefly about that before, but this is my first time chatting with Noelle, so I’m excited to hear what she’s got to say. And, um, yeah. Thanks for being on here with this Noelle.

Noelle Joy: Yeah. Thank you. Glad to be here.

Reed Preston: Yeah. So tell us a little bit about your background. Like what made you pursue horticulture?

Noelle Joy: Yeah, so when I first started undergrad, I wanted to go into nutrition science. I was really interested in the idea of food as medicine and seeing how what we eat impacts how we feel and our health. And I wasn’t – you know, I was thinking about going into some kind of clinical space, but – wasn’t really enjoying that and then started a garden at my house and was looking for some upper-level electives to finish out my undergrad degree. And I took an organic gardening class just on a whim ‘cause it sounded really interesting and thought it would help me with my home stuff. And there’s actually a student teaching farm here at the University of Georgia called UGArden. And I actually manage a program here now, but in my undergrad, in the class, there was a requirement to work out at the farm.

And so I came out here and I was immediately feeling as if I had found my people and found my community. And so I – the rest of my undergrad – I worked out here as much as I could. And then it kind of just snowballed into medicinal herbs and growing herbs. And that was kind of the catalyst that led me into a horticulture career.

Dana Mosman: Awesome. Do you feel like you were always on the Ph.D. track? Or how did you – obviously kind of switched horses there a little bit. Um, how did you decide, like, oh, I would really want to get into this? Or, like was there a single moment, or was it just sort of a gradual process?

Noelle Joy: It was a gradual process. I feel that I fell into a lot of things or the opportunities came up and I was the first person in my family to get an undergrad degree. And so I didn’t know about grad school, honestly. Like I just had no idea how it works. Didn’t have a lot of experience with academia. And at the last year of my undergrad, the director of the farm that I worked at – UGArden – he came up to me and he said, “Would you be interested in getting paid to get a master’s degree and doing it interdisciplinary between horticulture and food science?” And I was like, “backup, I can get paid to go to grad school. I didn’t know that.” And so that opportunity came and I just kind of ran with it, not thinking about any kind of future plans, but it just sounded like a really awesome opportunity. And then when I finished my master’s, there were people that wanted me to go on and get my Ph.D., but I wasn’t sure what I wanted to do.

And so I ended up managing an herb program out at UGArden for a couple of years. And through that experience, I really kind of developed a desire to work in academia and be a faculty person. And to do that, you kind of have to have a Ph.D. in. So it was a gradual process of kind of just being in a space and putting down roots and then seeing what opportunities came up and yeah, who knows now, you know, it seems like things are always changing and evolving, but I’ve been really enjoying my program and really, like, research I found during my master’s that I really enjoyed research. So.

Dana Mosman: Cool. So, in terms of your family, you’re the first one who graduated from college. So that’s pretty cool. Is there anyone in your sort of roots that you would say, like – do you have farming? Like is horticulture all new to you or did your grandmother or somebody, you know – like sometimes there’s a story there – is it uh, what’s your sort of family connection to horticulture if any?

Noelle Joy: Yeah. I wouldn’t, I wouldn’t say anything. I think maybe my grandfather had a green thumb, but I never really experienced that with him. Um, so, and growing up, I wasn’t outside at all, so it’s kind of funny that I’m just like this outside person now, because growing up, I was just inside reading books all the time. I was definitely like a book nerd and kinda had zero connection to the natural world. So all of this has been in kind of the later stage or not later stages, but, you know, in my twenties is kind of when all this happened. So.

Reed Preston: Nice. Yeah, so like, obviously you were working with different medicinal herbs before, but what drew you to hemp? You know? How did that – like 2018 when the Farm Bill was passed or was it after that? Like, how did you get involved in working with hemp?

Noelle Joy: Yeah, it’s been, it’s been really exciting and kind of again, was in the right place at the right time. So I had gotten the letter of acceptance for my Ph.D. where it kind of worked out perfectly because I was applying for grants to try to get my Ph.D. and trying to figure out how to get funded and still be able to do a medicinal herb project. And it is kind of difficult to get funding for medicinal herbs projects at the moment. I think that’s changing as more and more people are interested in herbs, but, um, I was looking for a project and at the same time, the 2018 Farm Bill passed, actually. And then we, uh, there was a vegetable extension specialist, Tim Coolong, who was appointed as the hemp person for UGA to start a hemp program.

And so I was talking to him kind of when all that was happening and I was looking for a project and he needed someone that had some background in horticulture and chemistry. Because it’s interesting with the hemp plant similar to other medicinal herbs is that we’re not just looking for yield. We’re also really trying to figure out – we’re kind of farming secondary metabolites. So in hemp, we’re farming, you know, CBD and CBG and different things like that. And the terpenes. And so having knowledge about the chemistry side of things and being able to extract and analyze it was a really big plus, I guess, in the skill set that I had.

And so it was kind of just perfect that he was looking for a graduate student and I had the skillset to do research on hemp. And, um, so yeah, it’s kind of in the right place at the right time.

Dana Mosman: That’s, uh, I noticed the chemistry coming in when we were doing our drying study. All the questions, like, all the questions that you had were about the chemistry. And, um, on the equipment side, we’re obviously really far away from chemistry. So it was really interesting for me to see that whole component play out. And there’s a lot, I mean, there’s a lot about the plant. Right? And there’s a lot of variables in there too. And so when you’re looking at the data it became apparent that you really have to have a strong understanding of that stuff to make sense of it. You know? Like I, I feel like there could be poorly scoped or poorly interpreted data out there that’s super misleading. So I hope there are more academic studies that come out that we know that the data is solid and the interpretation of the data is solid too.

Noelle Joy: Definitely. It’s actually interesting. I was talking to my advisor this morning about it because I am in the process of trying to analyze hemp terpenes. And I’m using an analytical, or a machine called a gas chromatograph, mass spectrometer. And what it does is allows me to separate all the terpenes and, and it’s like a really complex mixture.

There’s a lot of different kinds of terpenes. And what I’m doing at the moment is trying to figure out different parts. Like you can manipulate temperature to be able to separate the compounds better. And so depending on different temperature manipulations I’ve done, I’ve tried to figure out the best method to analyze them. You know. What was two compounds under one set of conditions actually turned out to be five compounds under a different set of conditions when it was like, when I have taken the time to figure out the best way to separate them. And so it is interesting. I was talking to my advisor, like if someone hadn’t spent weeks trying to figure out all these different things and they just kind of followed a method and a paper, there’s probably a lot of like quantification data on terpenes that potentially may or may not be fully accurate because, you know, because there’s a lot of compounds that are coming out at the same time.

Dana Mosman: Mmm hmm. Mmm hmm.

Noelle Joy: So it’s just interesting. And it’s taken me like – I’ve been doing this for several years now – how long it takes and how much depth of knowledge it takes to really like, understand it.

Dana Mosman: Yeah. And I would say like the traditional drying methods, at least in my interpretation of them, it’s like, basically, because there’s not a lot of data on drying. There’s not a lot of studies on drying. Right? Everybody basically understands that the terpenes burn off with temperature or dissipate with temperature. Right? And so they just say like, okay, cooler is where we need to be. And there’s a whole range there. So depending on, like, how scientific you want to be, different temperatures, depending on what you want to get out of the plant, you may be able to go faster or slower because those compounds are more or less volatile at different temperature ranges. Right?

So, I mean, I just found that fascinating as we looked into drying ourselves and, and like smell. That’s terpenes, right? So like when, when all the, like, when through the drying process, everyone tries to keep it cool ‘cause they want to retain the smell and, um, from my understanding and that’s all based on those volatile terpenes.

Noelle Joy: Um, yeah, it’s interesting. I actually just read something. There’s someone I’m connected to; Jason Wilson. He does a lot of education around cannabis, or around hemp. But he, uh, he posted something the other day about how there was a study that came out recently. That half of the aroma of the plant actually didn’t come from terpenes that came from aldehydes.

So what we’re smelling isn’t 100% terpenes. And so it’s interesting. And there really isn’t any study/studies done on that, you know, how drying might influence that, or even what type of aldehydes are there. And so, I mean, I could do a whole other Ph.D. just looking at, kind of like, sensory and chemical analysis of what makes up the aroma, especially if it’s not just terpenes.

And so someone could spend an entire career just focusing on that one thing. And it is good to understand the chemistry. And of course, I really enjoy the chemistry, but also just like, sensory-wise, you know, you can tell if something’s good or bad quality just by looking at it and touching it and smelling it. So I think there definitely is a lot to be said for people that have learned by doing it as well.

Dana Mosman: Yeah, for sure. For sure. I mean, it’s such a – there’s so much there. Right? So.

Noelle Joy: Mmm-hmm.

Dana Mosman: It’s really interesting. So what – I don’t even know –what’s an aldehyde? What is that?

Noelle Joy: That’s a great question. Um, you know…

Dana Mosman: Haha. Reed maybe knows. I don’t know.

Reed Preston: Uh. I sure don’t, Dana. Actually. I’d love to hear about it.

Noelle Joy: You know, I actually have on my list, like, “research aldehyde”. I don’t even, I don’t even know, like, how they’re analyzed. Um, it’s, it’s something that I’ve had on my list to look more into. But I will say like, – when this is just one example is like – if you have a bottle of oil, like vegetable oil or olive oil or something like that, and it’s gone rancid, and you can smell that kind of off smell, what’s responsible for that are aldehydes. It’s like a by-product of oil going off.

Um, so in hemp, you know, they would be like good smelling aldehydes. But I think it’s, like, highly volatile. Um, but I’m not exactly sure how it would be extracted and measured. So maybe on episode two, we can talk about that.

Dana Mosman: Yeah. Episode two. We’ll bring on Jason Wilson and you, and we can talk about that.

Noelle Joy: Perfect. Perfect. Hahaha.

Reed Preston: So I know Dana knows a lot more about the study that you, you know, you’re working on and that you guys have both, basically even been working off each other a bit from what I’ve heard. Um, but yeah. Could you tell me more about it? Like, you know, When it started. Where you’re at. You know. How much longer you’ve got working on your Ph.D.?

Noelle Joy: Yeah. I started with these lofty lofty goals of what I would study. And I actually was interested in doing large-scale drying studies, like maybe using a chicken house or a tobacco dryer or peanut dryer, kind of like large-scale equipment that might be available to farmers, um, and researching that. But I came across some roadblocks because we just really don’t know much at all about drying, especially in terms of, like, what’s published in the literature.

I think a couple of studies have come out in the last year, but before that, I think it was in the 1980s that the last study from hemp drying came out in terms of how drawing practices affect the chemistry of the plant. And so we really scaled it back after realizing that because there was just a lot of foundational work that needed to be done, kind of some basic information about what happens during the drying process and you know, how much terpenes are lost with different methods.

So all of that to say, we scaled it back and we simplified it. So from my research, I’m looking at four different drying methods and three of them are common methods used for hemp biomass. So that would be the leaf and flower. Uh, and so we dried it in a barn and then we dried it in an oven at 40° C and at 50° C. So two different oven temperatures and then barn drying.

And what we did is we analyzed the cannabinoids where we’re looking at 14 different cannabinoids and then analyzing the terpenes. And I’m extracting the terpene through distillation because a lot of studies will extract the terpenes through a solvent extraction using maybe ethyl acetate or something like that. And you can look at the profile of the terpenes with that, but you don’t know the quantity or like the fraction of terpenes in the plant.

And so with distilling it, I know, you know, 50 grams of plant material is going to give me this many grams of essential oil or milligrams of essential oil. Or terpenes, um, I use them interchangeably. So the terpenes and essential oil are basically the same thing. But, what I wanted to do is really see, like, what the terpene loss was over different drying methods. So that’s why I did the distillation. So I could actually see the weight of essential, uh, of terpenes, you know, before and after drying. So.

Yeah, so basically I measured the terpenes and the cannabinoids before drying and after drying. And then I took that material that I dried and I put it in bags and put it into storage and then sample it over the course of six months to see how those different drying methods also impacted the cannabinoids and terpenes during storage, uh, to see if, you know, it may be one of the methods caused a real high change in terpene profile, or, you know, trying to see just what was, ‘cause we’re not exactly sure what’s happening during all these different things.

So that’s one part of my study. And then the other part of my study, uh, we are really interested in looking at how, um, kind of what the industry practice was for smokable flower or kind of like the drying and curing process. And so I also did that. So I harvested a bunch of material and hung-dry it upside down in a room that was, um, uh, it was 60° Fahrenheit. I think it was like 15.5° C and then 60% humidity.

Reed Preston: Yep. Sounds about right.

Noelle Joy: Right. And so then we did that and then I actually sampled at different moisture percentages. So like at 20% moisture, 15% moisture, and then 8% moisture, I sampled for cannabinoids and terpenes. And then we cured them for two weeks. I trimmed off the leaves and had just the buds, the trimmed bud in five-gallon buckets with lids on it. And then I had temperature and humidity sensors inside and outside the bucket and then did the burping for 30 minutes a day, once a week, and then just had like the lids closed for another week. And, um, and then sampled it throughout the curing process as well. And then also put those into bags, into storage and then sampled it over the course of six months in storage.

So I ended up with like 168 samples with all of that.

Reed Preston: Mmm-hmm.

Noelle Joy: I’m actually, yeah, working on finishing up the cannabinoid analysis for that this week. And then in the next month, I’ll be finishing the terpene analysis. And so what I’ll have at the end of that is looking at four different drying methods and then seeing how the cannabinoid and terpene profile changes across the course of drying and storage of all of those methods.

Reed Preston: Wow.

Dana Mosman: So you have like…

Reed Preston: That’s super interesting. I know you said… Sorry.

Dana Mosman: No. Go ahead, Reed.

Reed Preston: Umm. haha.

Dana Mosman: Now we’re all curious. You’ve got lots of follow up.

Reed Preston: Yeah. I got a bunch of questions. But I know you said like 40° C. That’s like around 100° Fahrenheit, right? So, and that was in an oven. So how long did you leave it, you know, did you leave the flower in there?

Noelle Joy: So that was about, um, the one that was a 100°. It was, I’m trying to think. I have it in a spreadsheet. I think it was like 36 hours.

Reed Preston: Okay. Yeah. And were you like, were you checking on it and like flipping it? Or um.

Noelle Joy: Yeah, so I had, um, – ‘cause it’s a research study – I had replicates. Three replicates for, for every treatment. So I had three pans in the oven and I rotated them and I took measurements every two hours.

So I’ll have, like, drying curves from all of the drying methods as well, to see how long it took to go from fresh weight, all the way to the finished product. And so, yeah, I think the lower temperature one took – I can’t really remember – I think it was like, yeah, 20, 24 to 36 hours, depending on how wet the material was when it came in. And then the other one I think took like 20 hours.

Reed Preston: Right. Yeah, that sounds, that sounds pretty familiar. Like, uh, like I mentioned earlier, um, I was working at one of the first hemp drying facilities here in Oregon. So we were doing, um, you know, flash drying, I guess. But I think we’re hitting around like, yeah, a hundred, 104 degrees was like where we wanted to be at, you know, without, like, completely just burning off all the terpenes, but still trying to get that quick, dry.

And then, um, we’re drying around 10,000 pounds a day of dry weight. So, um, yeah, it was this extremely labor-intensive job. So we get in bays, you know, the, um, the drying facility was engineered by the farm that I was working at. But we’d have about five, 10 guys in there with pitchforks, just flipping the hemp…

Noelle Joy: Wow.

Reed Preston: …every six hours or so.

And then. Um, yeah, it’s just like thinking of that oven, I’m like, wow, that sounds so nice. Haha. You know, going back to those days, I’m like, man, an over would have been a lot nicer?

Noelle Joy: Yeah.

Reed Preston: But, um, yeah, we aim for around like 8%, um, you know, moisture at the dry, because, um, you know, just risking mold and all that is tricky, especially on that larger scale.

I think it’d be more, you know, you could control it a bit better with oven trays, but on that scale, we always had to get it real dry.

Noelle Joy: Yeah. I, um. Do you remember how you measured moisture? Now I’m gonna ask you a couple of questions. Haha.

Reed Preston: Haha. Yeah. Go ahead.

Noelle Joy: Well I was going just off of weight, so I kind of knew what the original percent moisture in the plant was. And so I kind of with a thousand grams, you know, in a pan, I kinda knew what the final weight that I wanted it to be, that it would be an 8% moisture. Um, but I was also trying to like, go by look, you know, because when you dry it in an oven, I’ve found because they’re so dense, the middle part is still bendy. Like the stem is still bending in green…

Reed Preston: Right.

Noelle Joy: …even though the outside is really dry. So how did you handle that? ‘Cause, that was a challenge for me.

Reed Preston: Yeah. So actually both ways. We did have a moisture meter. It wasn’t a Triminator moisture meter, but, um, we did have, um, it was more of a moisture analyzer. So it did the same thing that you were doing, but, um, you know, weighed it, and then it would dry. So like, we’d take, like, about a gram and grind it up and put it in there and it would take the starting weight and then dry it and then take the end weight. And that’s how just, just like you, but, um, I guess a calculator. And then by feel. The flower usually didn’t come in bucked, you know, most of it came still on the stem. So a good way for us would be to just go in there and, you know, just walk around and see what stems were snapping…

Noelle Joy: Nice.

Reed Preston: …to really know, because even if, even if the buds are bone dry. You know, if you’re leaving those stems in there with, you know, that still have moisture, once they’re in a bag, it’s just gonna spread.

Noelle Joy: Right.

Reed Preston: And then you could end up with, you can start with your flower at 8% and then, you know, end up at 14. So yeah, it was definitely a process. You know? It was learning for everyone. All the workers. I worked there for a couple years and every season, there were just so many changes that happen. It was crazy. And yeah, there’s no studies like this showing what’s right and what’s wrong, or what’s really going on in that whole drying process other than getting, a dried material. You know? Finished product.

Noelle Joy: Yeah. For sure.

Dana Mosman: Well was there a reason that you picked like the 40° and 50° C, like in terms of like, there’s a lot of temps you can dry it at, right? So like what, what was the reason for those two numbers?

Noelle Joy: Those were pretty close to what I use for my other drying; herb drying. We dry at pretty high temperatures. And, um, yeah, so I was kind of going based off what I felt like would be similar to – like, would dry it quickly, but not drive off too much of the volatiles and terpenes and things like that – so I was kind of basing it off of experience that I had from other herbs.

Dana Mosman: Okay. So yeah, that’s kind of, uh, that makes sense. I mean, one of the things I was going to ask is, how much has your experience with the other herbs educated this process. Because that’s one thing that I was doing when I was looking at drying technologies. Obviously, Triminator has or had a couple of dryers in our lineup and those originated from other drying methodologies. And so I’m just curious how much crossover you think there is, like, based on your experience with those other herbs?

Noelle Joy: I feel that I thought, or I guess going into it, I thought there would be more crossover. Um, but I find hemp to be kind of its own category. There’s just so many more considerations and things to think about in terms of even just the structure, the buds structure of the plants is very different than anything else I’ve worked with.

Noelle Joy: Um, and like with other medicinal herbs, holy basil for example you know, the whole stem will snap, you know, different parts. And it does have a really high moisture percentage and it takes a while to dry, but you know, we dry it at, Fahrenheit it’s between, like, 95° and 105° is kind of the ideal temperature for drying it.

And that really maintains all of the volatiles and things like that. And so, um, yeah, I think, and then, yeah, the whole plant, the whole stem along the whole plant will snap. And so I was kind of bringing that information into the hemp drying, and it’s just kind of different all around in terms of having more pest pressure.

The hemp definitely has more pest pressure than other herbs that I’m used to working with. And it has, um, yeah, the bud structure, the fact that it’s so dense, and how sticky it is. And I don’t know. Yeah. A lot of things. And so it’s kind of forced me to develop a whole new skill set and a lot more troubleshooting than I was expecting actually because I have found it to be quite different than other herbs that I’ve worked with.

Dana Mosman: Okay. Yeah. That’s interesting for sure. Was there a reason that you – was it just a cross-compare between the two types or the multiple types of drying there? Like, did you in the higher temperature version – when we have seen that sort of temperature range use, it’s typically for biomass – is there a reason that you did it on whole buds? Obviously, a whole bud is a lot more difficult to dry than a biomass product, just because the surface area is, uh, relative to the overall weight, like, it’s just tough to get in the center, which I think you alluded to. Um, why were you trying to do it as a whole, but in that situation?

Noelle Joy: Yeah. So what – and this might’ve just been because of the experience that we had. So we had done some variety trials and what we did was hang them upside down and dry the whole plant in a greenhouse and then buck the material and then take weight on the dried leaf and flower, dried leaf in bud.

And that’s kind of what we were seeing was used for biomass for maybe doing some kind of like CBD extract or isolate or something like that. And so basically what I was trying to do is figure out how to analyze what that product would have been, you know, the bucked dry flower and leaf. Doing it on, like, a research scale.

And so that’s kind of how we got to that is we bucked it fresh and then did the leaf and flower in trays in an oven. I’m trying to think of, yeah. Like, if someone were to do large quantities of it and at some kind of larger oven for biomass, for an extractor, an isolate, ‘cause you know, I was really, for that I was thinking, you know, at higher temperatures, you dry it faster. And if you don’t really care about the terpenes, if you’re just doing an isolate and it doesn’t really matter, you know? So the idea would be, we’re just kind of providing information for really baseline practices. Um, so people just have an understanding of when they make a decision, this is kind of what’s going to happen. Does that answer your question?

Dana Mosman: Yeah, no. I mean that is helpful because, like, the baseline knowledge is really what’s missing because everyone is basically just doing it by what they know happens like, oh, it stopped smelling at this point in time, you know, or it starts to really get brown here.

But like I said earlier, I mean, I think as hemp gets to be a more sophisticated crop and there’s more of it available. I mean, one of the things that I see potentially happening – like the dollar per pound of hemp is really high compared to other agricultural products and we haven’t really grown it at a huge scale, but you know, like a lot of products are just grown for one specific, like canning tomatoes, right, is a different variety of tomato then when you get for your salad.

Noelle Joy: Exactly.

Dana Mosman: And so I imagine in part of the industrialization of hemp will be that sort of like on both the agricultural side and the growing side. And then also just with how it matches with how you’re able to process it. You know?

Noelle Joy: Exactly. Yeah.

Dana Mosman: So having that baseline knowledge of like, okay, we don’t really care, like you said about the terpenes, we just care about the CBD or CBG or whatever. And like how hot can we try that and not lose it, um, will be great information to have.

Noelle Joy: Yeah. So in a certain sense, I kind of feel like my research is just telling everyone what they already know, haha, which feels not quite as groundbreaking, but it’ll be hopefully, you know, in a peer-reviewed academic journal that then people can reference and say like, “okay, we have the data to back up what we’ve felt all along.”

Dana Mosman: But also different compounds, right? Like you’ll know the different compounds, which I think will be really valuable because that will educate different methodologies depending on what you’re trying to get out.

Noelle Joy: Definitely. And for people to be able to say, okay, like now that we understand this is what’s happening, here’s my suite of options for what I can do with it, and then how I might need to process it to make the finished product that I’m interested in. So, yeah.

Dana Mosman: So, like, relative to the way that your test scores were done, how much of that came over from your experience with the holy basil or, or are there other methods that people use in herbs that you think could apply for this? Or do you feel like it’s so different that it doesn’t apply?

Noelle Joy: Um, I am unsure of the question. So is it that, is it like methods of analysis for…

Dana Mosman: Well, I have a question on that too. Um, no, my question is, like you said, that holy basil is dried in a certain way. And like I’m sure different types of herbs are dried in different ways. But do you feel like hemp deserves, like, an entirely different process, like an entirely different, um, just based on your experience at this point in time, um, you think it’s like pretty much entirely different processes?

Noelle Joy: I mean. Again, it kind of goes into like what we want to make out of it, but really, you know, at the higher temperature we are losing a lot of volatiles and that might be because of the structure of the trichomes like the trichomes, you know, are the, are the, um, kind of appendages on the plant that come out kind of like hairs, I guess, on the plants.

And then some of them contain these cannabinoids and terpenes and then in hemp, they’re very pronounced. And so in other medicinal herbs maybe the structure of the trichome is different. And so it influences what happens during drying, because with other medicinal herbs, I guess the point of saying that is with other medicinal herbs, we can dry it at a higher temperature and not lose as much of the terpenes as we do with hemp.

And the fact that with hemp, we do this slow, cool, dry, and cure process. That’s pretty different. All of that to say, I feel like it will be kind of in its own category, and pretty different from other plants.

Reed Preston: Speaking of, like, you know, just growing and everything, you mentioned that you were planting some hemp earlier this morning. What genetics are growing out there?

Noelle Joy: Actually, shout out to Dr. Justice, Dr. Allison Justice from The Hemp Mine. We’re using some of her genetics.

Dana Mosman: Yeah

Reed Preston: Oh Nice.

Noelle Joy: Yeah. So she gave us two varieties. One of them is Sunset. One of them is Bell. And they will flower three weeks apart from each other. And so it’ll be really nice that I have a pretty extended season of harvest that I can, you know, use that plant material for my research and potentially do some additional things. Because that was the issue last year, I wanted to study more things. And I actually was talking to someone in our food science department at the University of Georgia who does a lot of drying, and I was going to try to use his freeze dryer and a few other things. And then we just ran out of time in the season, you know, then, um, everything kind of started going down in the field and succumbing to mold and things like that. And so it’s nice to think about this year. I have some more time where the flower will be ready. And then we can do some more tests.

Dana Mosman: Yeah. You guys. I mean, I’m glad you got those from her. Cause I was at one of Allison’s field days and uh, she was just talking about all the pest pressure in the south. And the south is a region that like – actually there’s a guy that we know who, who came from, I think he’s originally from South Carolina that he moved to Oregon learned to grow hemp and then moved back to South Carolina and was just like, “oh my God.” They’re like, it’s just like whack-a-mole of pests. He’s just like, “it’s like guerrilla warfare out here” relative to the pest pressure. And, uh, and that was kind of like Allison’s point too is like the genetics in the south have to be so robust, because of all the humidity and the pests. And so, uh, it seems like a good fit that you got some southern genetics there.

Reed Preston: Yeah, that’s great. It’s definitely pretty humid out there, right?

Noelle Joy: Yeah. We have a really nice long growing season, but the downside is that we have some pretty heavy clay soils and really high humidity. And I remember the first year it was, it was a variety trial we were doing. This was in 2019. And we were harvesting and there were so many worms. Like I had worms like falling off my hat and crawling out of my backpack from, in the room where we were racking it up. And it was, it was wild.

Reed Preston: Dang. Yeah. How does, like, how does the humidity play into the drying process and then like curing as well?

Noelle Joy: Yeah. So really just being in controlled environments. It’s difficult to dry it successfully and consistently outside, I would say, or under kind of ambient conditions because when I was drying it in the barn, it was just an open-air barn. So it had a roof over it, but it was, you know, had cross-breeze coming through from outside. And I had a temperature and humidity sensor set. ‘Cause I was monitoring that for all the different drying methods. And one day it was 90% humidity when really trying to dry this material outside. And so, especially if there’s any kind of spores on the plant from the field, um, you know, that’s just going to proliferate under those conditions when it’s trying to dry.

So if you have the perfect weather, you can definitely play with that a little bit, but a lot of times it’s just really humid and that makes it challenging to dry. And so we have to use more controlled environments.

Reed Preston: Yeah. Yeah, definitely. I’ve seen some guys pull it off, you know, in August around here in Southern Oregon, but you know, then you get into yeah, October, even. Last year or the year before we had some early September rains and yeah, definitely, definitely doesn’t help if you’re dry in an environment that’s not real, you know, real controlled or yeah. It can be rough.

Noelle Joy: Yeah. And it’s kinda like, you know, it was almost done and I was about to pull it and I was like, I’m just going to wait one more day. And then it got really rainy for a couple of days. You know? And, and then it kind of rehydrated a little bit. And so there’s a lot, again, that’s kind of like trial and error, a lot of learning kind of on the fly of trying to sense what the weather’s going to do and when to pull something, you know, so.

Reed Preston: Yeah, for sure. It’d be interesting actually talking about, like, rehydrating. I wonder, like, what a study would be like, uh, you know, if you were to get something down to 6%, you know, and see what’s going on in the terpene world there and then rehydrate it. Would any of those come back? Or, you know, some would say yes, I guess.

Noelle Joy: That’s a great question. That’s a great question. But yeah, someone should do something. Someone should look at that. Hahaha.

Dana Mosman: Someone should study that. Gosh.

Reed Preston: Someone get on it.

Dana Mosman: Did you piggyback at all on – Alison had done a test on curing. Pretty solid. The first one I’d ever seen – did you piggyback on that at all? Or, um, similar methodology, I guess?

Noelle Joy: Yeah. I definitely looked at her presentation, you know, what she had found, and then consulted with her when we were designing the study.

So, um, yeah, even just like how we structured and what temperature we did the drying and curing at, and then how we did the, you know, with the buckets and when we, how we trimmed them. And all of that was kind of based, um, piggybacking off of what she had done.

Dana Mosman: In all the, um, in all of your tests, it was bucked flower with the leaf still on, untrimmed.

Noelle Joy: For all of them, except for the drying and curing. Like with the, um, at 60° Fahrenheit, and 60% humidity. That we hung to dry whole plants and then we trimmed the leaf and then just had the buds that we were curing. So that was kind of more. So they were kind of two different types of our sets of drying studies. One was the biomass where we did the oven and the barn drying. And then the other was kind of more like what someone might do for smokable flower.

Dana Mosman: Right. And on the smokable. I mean, I’ve seen it myself and everyone. Well, a lot of people swear by it is like basically leaving it whole plant, or at least like on the stems, in terms of the terpene profile. Do you have any hypothesis on why that is?

Noelle Joy: During the curing to leave it on the stem?

Dana Mosman: Even during the drying process. Do you agree with that, Reed, in terms of what’s most common from a, like, a smokable perspective?

Reed Preston: Yeah, definitely. You know, if you’re not wet bucking and wet trimming, which I think we had that battle. That webinar battle. Um, but yeah, for sure, like if you’re, um, you know, if you’re hang drying.

You know, I see some guys that’ll buck and dry on, you know, racks and all that. But I do think that leaving it on the stem, you know, you’re preserving more terpenes and you’re going to end up with a better product.

Dana Mosman: So that’s the farmer’s knowledge, there. Do you have any reason, like, why do you think that’s the known – like, do you have any interpretation at that from a scientific perspective, Noelle?

Noelle Joy: I mean, I did do some – from a scientific perspective, I’m not sure, but I guess I’ll kind of say, like, something that I looked at.

So we will always process our herbs, like the ones that we need to remove the stem. So holy Basil’s one that we need to remove the stem and we would never do it fresh. We would do it dry because fresh it’s, um, just you damage a lot more of the plant material, um, by trying to like ship it fresh. ‘Cause everything’s so connected to each other, you know, when it’s dry, you can just like strip it really easily. But when it’s fresh, you’re kind of damaging more of the cell wall and the membranes and the trichomes and things like that. So, um, and then I actually was trying, was doing, developing the method to do my distillation, to extract the terpenes. And I was trying to figure out the best way to grind the plant material. So I was trying different methods of grinding, extracting it, and seeing if there was a difference in the quantity of terpenes. And I tried using, like, a coffee grinder on the fresh material. And then I tried kind of like passing it through a screen to get it, to break up into consistently sized pieces. And when I passed it through the screen, I lost like 50% of the terpenes. Um, so really I’m thinking that bucking it fresh and losing the terpenes is more of just a function of like you’re handling the material more. And you’re kind of just, like, smashing those trichomes and losing the, you know, losing the compounds that way.

Reed Preston: Yeah, I definitely agree with that. One thing just came to mind too, also with the hang drying, again, not proven, but you know, when it is hung, you know, you’ve got waterleaf and other larger leaves that are, you know, they end up, you know, if they’re upside down hanging, they end up, like, wrapping around those buds and potentially preserving more terpenes. I think that’s another argument, I guess, but again, not proven.

Dana Mosman: Man, we’ve got a little work for the academic world.

Noelle Joy: I’ll add it to the list. I think I’ve got like five PhDs worth of things at the moment I’m, like, interested in. You know? We’ll add it to the list.

Dana Mosman: Yeah. We’ll keep you going, Noelle. We got you.

Noelle Joy: Perfect. Perfect.

Reed Preston: Come and just work on a Ph.D. on the wet trimming versus dry. Right?

Noelle Joy: Oh my gosh. That’d be so interesting. I mean, I think it’s probably a bunch of different factors that all coincide together to influence why it’d be better to, you know, and there might be some enzyme activity that’s happening, you know? I mean it, yeah. There’s so many things that could be.

Reed Preston: Yeah. For sure.

Dana Mosman: What, um, I guess one more, uh, this is sort of very science-y and we’re kind of jumping around a bit, but like when we were doing our study and you were weighing in on it, you had a lot to say. Like, we were cross comparing methods in terms of, uh, even examining the volatiles.

And we got into different labs and how different labs were interpreting data. Can you give us a high-level view of how that’s done and, um, like how, why you chose the method you did maybe?

Noelle Joy: Yeah. Yeah. Um, in terms of just in general, how just the terpenes are analyzed in the lab?

Dana Mosman: Yeah.

Noelle Joy: Yeah. So with hemp terpenes, um, it’s funny, you know, I’m thinking about all the different things that I could talk about or a lot of that it depends on the lab and what equipment they have and what access they have to things. So usually you would have some kind of basic method, uh, and that means that you have a set amount or, okay, sorry, let me back up.

So where we start is that usually you would use gas chromatography to analyze terpenes ‘cause they’re volatiles. And so what happens is it’s this oven, a gas chromatograph that has this really long, thin tube. Um, and the inside of the tube is coated. Uh, they can be between like 30 and 60 meters long. Sometimes longer.

Dana Mosman: Oh. We lost you there. I lost you anyway. Did you lose her, Reed?

Reed Preston: No, I didn’t lose her. I was trying to follow and try to keep up with what was going on.

Noelle Joy: Let me, um, yeah, let me start over. So in answer to your question, the high-level view of how terpenes might be analyzed is that there’s a piece of equipment called a gas chromatograph. And basically what this does is it allows us to separate complex mixtures into individual compounds, because terpenes, or essential oils, you know, they’re highly complex mixtures. They can have a hundred plus compounds in a single, like, terpene sample. And so what we want to do is identify what all those compounds are. And so we need a way to separate them. And so the gas chromatograph will separate them and then it can be attached to different kinds of detectors. And so, um, one that a lot of people will use is a mass spectrometer detector.

And there’s a lot of, kind of, science and chemistry that goes into how that works. But basically, it’ll allow you to identify what the compounds are because it’ll give you, like, a fingerprint that’s unique to that compound. And so basically it’ll be able to separate the sample and tell you what’s in it.

And there’s different ways that you can introduce your sample into the machine. And you can do, um, there’s something called SPME. And basically, you’ll heat up the sample and then there’s this needle that goes inside of the vial that’ll absorb all the volatiles that are kind of like going into the air, kind of, if you would use a diffuser, you know, you can smell it in the air when you diffuse it into the air, that’s kind of what it’s doing.

And so there’s this needle that gets all those volatiles and then injects it onto the machine. Or you can just take, like, a diluted sample of the terpenes and inject it onto the machine.

So there’s different ways of introducing the sample and the answer to why you would do that kind of depends on a lot of different factors. So I don’t want to get too much into the weeds, but, um, yeah, what the lab will do then is figure out what are kind of the most commercially common terpenes that people are going to find in all the different hemp samples. And then they build, um, they have like pure compounds of that, that allows you to kind of figure out how to quantify them.

And, and so what you’re doing when you send a sample off to maybe a commercial lab or something is just, they have a set number of compounds that usually you find in all the different hemp samples that are commercially relevant and you can find standards for, which is like the pure compounds, and that’s what they’ll measure.

So depending on what’s in your sample and the quantity of terpenes in your sample, um, you know, the results that you get back, it might not be like every single terpene that was in your sample. It will just be the ones that they are able to quantify, because of the method that they use. Because there’s another detector that is better for quantification, it’s called a flame ionization detector and that, um, you can’t tell what the compounds are, but once you’ve identified them, then you can quantify using that detector.

So all of that to say, um, if they had a hemp sample that had a lot of things that they weren’t used to quantifying, they might not know what those compounds are. ‘Cause they’re kind of just, you know, analyzing the ones that they – that’s in their protocol basically.

Dana Mosman: So it doesn’t necessarily mean that it’s not there. It just means that they can’t – they’re not testing for it.

Noelle Joy: Exactly. Yeah. ‘Cause, it’s just, it’s a lot of work to kind of go by an individual hemp sample and separate everything out and analyze everything that’s in that sample because it is so complex and there’s a lot of variation among plants. And so they kind of, yeah, they kind of have a selection of turbines that they’ll always analyze.

And then, um, I mean, it’s kind of that way for cannabinoids too. You know, what we’re typically looking for are the big hitters, you know, CBD, THC, Delta-8, Delta-9, CBG, you know, there’s these common ones. And then there’s, in our samples there’s like other peaks, but, you know, we don’t really have the means to identify what they are, and we don’t have the standards for them, so we can’t quantify them. And so some of the samples might have high amounts of another cannabinoid, but because it’s not in our protocol, we can’t really analyze it.

Dana Mosman: Right.

Reed Preston: Right. That’s what I feel like. That’s why, uh, you pay more for the full panel testing. Right?

Noelle Joy: Right. And, and for us, developing – ‘cause each lab has to kind of develop their own method for how they’re going to do that based on the equipment and resources that they have – and so for us, it took us six months of just developing the method to analyze the cannabinoids and, um, you know, and if we wanted to measure more cannabinoids, it would have taken us longer. Um, so it is, you know, a lot of people I think will probably balk at lab prices ‘cause it is expensive to send material and to get tested, but it is just, it’s a lot of money and like expertise and time and, you know, um, equipment and consumables, you know, like pipettes and lab tubes and things like that, to be able to analyze the sample.

Um, and I’m actually really interested. I don’t know, have either of you heard of NIR testing?

Reed Preston: Um, I’ve heard of the DEA that was going to start testing in 2022 or something, correct me if I’m wrong, but no, I haven’t heard that.

Noelle Joy: Yeah. So I’m really excited about this and this is kind of where I’d like to see some of my research going is – so there’s primary methods of analysis. So that would be, like, HPLC (high-performance liquid chromatography) that we use to analyze the cannabinoids or gas chromatography that we use to analyze the terpenes. So those are primary, but what you can do is you can take your sample and then put it in an NIR machine (near-infrared) and it’s, like, a light that shines on it. And then it gives you all of these results. I’m not exactly sure the science of how NIR works, so I can’t go into that. I’m just, like, learning about it, but basically, it’s a secondary test. And you can program it with the results of the primary analysis to build, like, a curve. So then you can just – it takes like a couple of seconds to put your sample in there – And once you’ve programmed it, then it’ll tell you in like a few seconds what the level of CBD is in your sample.

Reed Preston: Right.

Noelle Joy: So instead of, like, a $70 test or a $100 test, you can do something for like $20 or less.

Dana Mosman: Interesting.

Reed Preston: Yeah, I think they actually – I know one of the companies making those is called Purple

Noelle Joy: Mm. Yes. Yes.

Reed Preston: And they’re like little, they look like a little Pelican case. Um, but yeah, I think they’re about 1500 bucks or so. Yeah, like you’re saying, it works off the light in, uh, spectrums in the light to get that, you know, CBD or, um, you know, uh, less than 0.3% THC is what you’re going for. Um, but I don’t know. I’ve heard like, you know, I’ve heard mixed things. I haven’t actually like, um, I don’t own one myself, but I’ve got a couple of friends that do and every time I’m like, “you think that’s right?” and then you’ll test it again. And, you know, you’ll test a different bud and it’s not. You know, it’s close, but it’s definitely not, you know, it’s not the same as sending it to lab.

Dana Mosman: University of Kentucky – I don’t know if you’ve seen this study Noelle – but University of Kentucky did, like, a national lab test where they were basically seeing how accurate, uh, all the labs were relative to each other. And it’s a wide spectrum, um, which I guess goes to show you it’s a complex process, right?

Noelle Joy: Yes, actually. We’re a part of that program, so it’s their proficiency program. And so it’s actually really cool because they send it to 40+ labs and then collect all that data. And then they give you kind of reference ranges for what you expect to find in that sample of hemp. And we use, so we use some of that for our quality control or quality assurance. And so we’ll measure that, we’ll extract that hemp sample and measure it and then compare it to the expected values to see, like, how close we are in our precision or accuracy, I guess, of the analysis.

So that’s cool! I’m glad you heard about them and, and it is wild because on their website you can look through all the different labs and what their methods are. And there is a wide range of methods that are used.

Dana Mosman: Yeah. Wide range and a wide range of results as well.

Reed Preston: Yeah!

Noelle Joy: Yes. There’s not really an industry standard at the moment.

Reed Preston: That’s. Sorry, go ahead, Dana.

Dana Mosman: Oh. I mean, to me, that coming from an industry perspective, what that means is like, some people are, could potentially be losing out on a fair amount of money. Right? And like, if you take it to a lab that’s under-reporting. And on the flip side, like there could be a, you know, if there’s a bad actor out there, there could be labs that are over-reporting because they want to, like, people are going to take it if you’re always a point or something over one lab versus the other like you’re going to take it to the one that results with the higher percentage. So it’s an interesting problem.

Noelle Joy: Yeah.

Reed Preston: No, definitely. And that’s why I think that’s why, like, I mentioned before the DEA thing, I think it’s got a lot to do with that, you know, um, you know, whether it be false, you know, false tests or whatever, I know that the DEA is trying to come in and sort of regulate that. Do you know much about that Noelle? Or…

Noelle Joy: I wish I knew more about that. I haven’t followed along as much on the political side of it. You know, how the DEA is handling it, so yeah, that would be something I’d have to report back.

Reed Preston: No right. Or what’s it, uh, episode two or

Dana Mosman: Noelle’s mini-episodes two.

Noelle Joy: hahaha.

Reed Preston: Own Your Harvest Noelle Joy episode two.

Noelle Joy: Haha.Yeah. I try to tell people it’s like, there’s so many aspects that you can learn about the plant. So one would be like the field stuff and learning about, you know, growing it and more or the pest and disease pressure and all of that. And then there’s kind of like the regulatory side of it, you know? And then the health side, like, you know, people ask me, “Is this a good hemp product? How much CBD should I be taking?” And I, you know, I say I have no idea. I’m not a health provider. I really am just a scientist. So I, yeah. The legality and regulatory side of it, I’m not as well versed in.

Dana Mosman: So where, um, I mean, I guess this is sort of like circling back to the study. So like, obviously we heard about kind of what you did, and kind of what your goals were. Um, what do you – where are you now and kind of, what are the next steps for you?

Noelle Joy: Yeah, great question. I finished extracting all my samples and I am almost done with the cannabinoid analysis. I will be by next week. And I am almost ready to do my terpenes. I’m still working on the best way to separate out all the compounds so I can quantify them. So I’m hoping that by the end of July I’ll have that done. And then I’m going to meet with my committee and kind of share the results of what I found for my first-year research. And then they’ll weigh in about things they’d like me to tweak for the second year. Or different little tests that we could add in. Like, we might actually send off a series of samples to get yeast and mold counts from the different drying methods, especially as it relates to storage. So I think that would be really interesting and kind of tell more of the story of what’s happening.

If we’re looking at the cannabinoids, the terpenes, and then the presence and amount of yeast and mold. Um, so we might – so different things like that, and then partnering with someone in food science to see if we can use their freeze dryer and include that. And see, um, since that is kind of well-known to maintain the highest quality, and it’s not feasible to use freeze-drying on a large scale, but at least it gives us some kind of comparison.

So, so all that to say, I’m going to meet with my committee and then see what things I might want to add when I redo my experiment. And then when the hemp that I planted today comes into season and usually it’s end of September, beginning of October, then, then I’ll do the whole study again.

Dana Mosman: Yeah, that’s awesome. That’ll be cool. So next time we talk, do you think that you will be able to share some results, uh, preliminary results from your study?

Noelle Joy: I mean, I guess it depends on when we talk next. Haha.

I mean, I would definitely be happy to share. You know, I feel like I would share this at a conference or something like that. So, um, yeah. I, as long as I feel comfortable in terms of speculating on what I, you know, like how much of the statistics have I done? You know, things like that. So depending on where I’m at in the process and how comfortable I am to kind of say, this is what we learned or not. Um, but in general, once I know those things and feel comfortable, then I’d be happy to share.

Dana Mosman: Right. Yeah. For sure. For sure. No, I mean, I think that’ll be good because like we know there’s not a lot of data, so it’ll be good for everyone to understand what’s going on for sure.

Noelle Joy: Yeah. I’m really excited to be able to have some graphs and see trends and patterns and have some numbers associated with, again, like you both were saying kind of what we’ve determined or figured out just from experience, having some numbers to back up what our experience has been, I think will be really exciting,

Dana Mosman: Right. Yeah. No, that’ll be great. And also to educate all those future studies that we outlined in this podcast, right?

Noelle Joy: Yeah. Anyone listening to this, you just take it and run.

Dana Mosman: Yeah. Just grab a couple of those. Um, so yeah. Reed, what else you got?

Reed Preston: Man, I think, you know, I think that’s it. Thanks so much for coming on here with us, Noelle. And, uh, yeah, we had a great time chatting with you. I’m really excited to hear, you know, the results of what you’re working on right now. Um, yeah.

Dana Mosman: How can, um. Yeah, Noelle, how can people find you? I mean, I know you’re on LinkedIn. If they have questions about your study, especially academics, right? There’s not a lot of research going, how do they get a hold of you?

Noelle Joy: Yeah, they’re welcome to find me on LinkedIn. Uh, my email is noellejoy@uga.edu. So you’re welcome to send me an email. And then actually on Instagram, I post a lot about the research that I’m doing and what I’m learning and, you know, different science education things among other things, and what I’m doing at the farm. I post all that on Instagram. So that is @iamnoellejoy. That’s my Instagram handle. So you can find me there.

Reed Preston: Well, yeah, thanks so much. Yeah, make sure to join us for upcoming podcast episodes. We’ll be chatting with Jeremy Babbit. He’s also known as 918OG out in Oklahoma. Um, we’re going to be chatting with him about rosin practices and the Oklahoma flower market.

We’ll also be having CJ Schwartz on here with Industrial Hemp Genetics. We’ll be talking about breeding and a whole bunch of fun things with him.

So yeah, thanks so much for listening to the Own Your Harvest podcast, powered by Triminator. If you’ve enjoyed this podcast, please subscribe to the show and share it with your fellow growers and farmers. Really appreciate you guys.