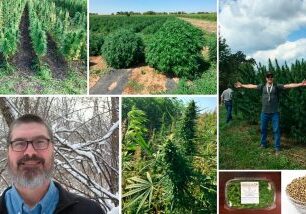

In this episode, we will chat with Mike and Rick from Royal Gold Soil in the heart of Humboldt County. Mike and Rick host their own podcast, Royal Grown Radio, a cultivation- and cannabis-focused podcast. We discuss NorCal’s legacy growers’ challenges as they transition to the commercial market.

Our hosts for this episode are Reed Preston, founder of Preston Hemp Co, and Dana Mosman, co-founder of Triminator.

Transcript

Intro: Welcome to Own Your Harvest, powered by Triminator, global leader in cannabis harvesting equipment, we will be bringing new, valuable insights from the front lines of the cannabis industry, giving direct access to our award-winning team and educating you on a variety of topics. From field service to extraction, we have lined up some amazing guests for 2021 to kick off this new podcast. And now, here are your hosts Reed Preston, founder of Preston Hemp CO and Triminator ambassador and co-founder of Triminator, Dana Mosman.

Reed: Welcome to the Own Your Harvest podcast. This is the seventh episode of our podcast series. I’m Reed Preston, founder of Preston Hemp CO and ambassador for Triminator. I’ll be hosting this series along with our Triminator co-founder, Dana Mosman. This episode, we’re going to be chatting with Mike and Rick from Royal Gold Soil in the heart of Humboldt County. Mike and Rick host their own podcast, Royal Grown Radio, a cultivation and cannabis-focused podcast.

Dana: Awesome. Thanks Reed. And thanks to Mike and Rick for joining us today. Always great chatting with other folks in the industry and definitely those from Nor Cal. So thanks for joining us and let’s jump in.

Mike: Hey, thanks so much for having us.

Rick: No doubt.

Dana: Yeah, right on. So, you guys are in Humboldt, you mentioned earlier, you guys are just chilling in the headquarters up there, or?

Mike: Yeah, we’re sitting in the heart of Humboldt County on the north coast of California in Arcata, California at our corporate offices, our sales and accounting offices. Our actual soil facility is just up the street about two miles, so we’ve got a really nice flow between our office space and our manufacturing facility, but a little bit of separation to keep a nice, quiet work environment over here, where we’re cranking through things and a little more chaotic and wild environment where they’re throwing that soil and bags for everyone.

Rick: Yeah, there was a time in history when our computers were covered in coco dustand you’d be on the phone just trying to understand what your customers are saying. And we realized that there was a need for some change, just a little separation goes a long way.

Dana: Yeah, for sure. For sure.

Mike: Yep.

Dana: Are you guys, so you guys have been doing it for quite a while and what’s the progression been for you as a company? Obviously, from the very start to where you are now?

Mike: Well, I’ve been with Royal Gold since late 2007. So, I’ve been here a good long while. That’s before we were actually manufacturing our own mixes. We were working with a co-packer, that’s business that’s no longer alive as its original entity, it’s been purchased and changed hands. But we were having somebody co-pack our recipes and then bringing in like six trucks at a time and working through that for a month or two or three, taking it out in our own delivery truck, delivering it to small local grow stores like North Coast Hydroponics, NHS, it was super small but North Coast Horticulture Supply. Let it Grow was another small local business. And we were actually out there delivering our individual pallets to all sorts of stores, Sylvan Dales, a lot of the foundation stores of Humboldt County that really built the scene here by having what people need, providing creative ways to get them what they need.

We worked with just trying to get ourselves into the industry. And we had so many problems with the co-packed product because we didn’t have control over every aspect of it that we just weren’t happy with it. We had some complaints and it came to a point where it was, “Hey, either you guys manufacture this stuff or we’re going to have to go another direction.” So we just did it ourselves. We found a facility. The original owner and current owner worked together to come up with a plan to manufacture our own soils to a new level of specification that people in the soil industry weren’t doing. We had quality control concerns that were high above what we were seeing coming out of any other manufacturer. And we were like, “Hey, we’re cultivators. We’re not happy with the inconsistencies of every product on the market. We haven’t found something that fits our needs that we can use right out of the bag.”

And when you start looking at an economy of scale, making your own soils for a big facility is a huge undertaking and was very, very difficult. So, we really worked hard to make product that matched our demand for quality, consistency, and cleanliness, and started making it, and experienced every setback and challenge and mistake along the way, and it got to a point where we’re able to really hone those pieces in and have a product that people can buy anywhere in the country and know that they’re getting the same thing they bought last time they bought that bag for the most part.

So, it really allowed a different level of accountability. And I feel like it’s elevated the entire soil industry by us getting behind that concept.

Rick: Yeah, like Michael said, with the quality I was a grower here and had my own space and was experiencing those issues with consistency and trying to figure things out on my own, which obviously is a whole different job. You’re either a grower or somebody that’s making products. And to take on both at the same time really was quite a bit challenging. So, I was one of the first, I would say, truckload customers for Royal Gold. In 2008, spring of 2008, I brought in almost two full truckloads of our Mendo Mix up to our property, and absolutely fell in love right from day one and just never looked back and continued to use it for several years until joining the family in 2014.

Reed: Nice.

Dana: Nice. That’s awesome. I have a similar story with Triminator. Actually, it’s funny. I purchased some XL’s back in 2018 and here I am now.

Rick: That’s that loyalty that you’re passionate about the product you use. Before I was getting paid by Royal Gold, I was out there telling anybody that I possibly could that this is the best product that you could use if you’re trying to be successful and work with consistent companies, with companies that have great customer service and good intentions behind them and really care about the success of their customers, then this was a no brainer. So yeah, before I was getting paid, I was already a big-time full-time advocate.

Dana: Yeah, for sure.

Reed: 100%. It just makes sense, you’re like, “Wait, I’m doing this anyway, man. Let me just jump board.”

Mike: Same with me, and I was such a huge advocate of coco in the mid-2000s and was like, “All right, Hey, everybody’s running peat-based soils, coco’s the next thing.” And there were really only a few companies doing it. There weren’t mixes out there. It was pretty much coco in a straight bag. There was your canna, your house, and garden, your Tommy, things like that. But it was all just straight coco. And there was varying effective levels of buffering. And there were issues with the salts and all this. And I was so passionate about it that I wanted to be involved in coco because I’d been cultivating already for 15 plus years in peat mixes. And I was like, “This is a sustainable answer. I’m all in.”

And went into my local grow store to buy coco soil, all my ingredients, and the woman there was like, “Oh, hey check out this new local coco.” And that’s how I got turned down to Royal Gold and was like, “Oh wow, super cool.” She’s like, “Yeah, these cool local folks.” I’m like, “Oh, I know them.” And that’s what drove me. I was like, “I want to get behind this. I want to be a part of this.” This is something that can change horticulture as we know it and change big ag and traditional gardening in a big way towards a more sustainable path as well. And if we can get together, get some education, improve the quality of coco and get that buffering handled, then I think we’re really onto something as an industry as opposed to even just as a cultivator. So that’s really what brought me in.

And I agree it was that passion that had me grow within the company to be out there selling it because every chance I got I’d be extolling the virtues of coco and preserving some of the peat reserves more effectively. And that’s still our path, is to work on sustainability, bring new products to market that are more sustainable alternatives to the current things out there, but that are effective solutions to the issues that we all face.

Dana: That’s pretty interesting. And I had a question in here that was basically, what other industries do you reference? Or like, where did coco come from? And then as you apply that to big ag, tell me a little bit more about the big ag aspect, or how can you take what we’re doing in cannabis and move it to a larger stage if you will?

Rick: I think the coco coming out of Holland from roses and tulips and such and it made its way over here, obviously, because Holland also had a cannabis industry. As far as I remember that was the first few people that brought coco into my ear was people that had gone over there and come back and they were like, “Man, this is a pretty new and innovative media to use for cannabis.” And like Michael was saying, it was trying to use your own ingredients to make your own. And it was definitely a little challenging, not knowing the actual recipe to use. And then of course there were not all coco is created equally.

So yeah, and then bringing coco into gardening in general, I feel like the usability, the functionality of coco, it’s, in my opinion, a lot better than Peat Moss, in not just the day-to-day way that it functions, but also just the longevity of it. When you’re actually looking at regenerative farming and building, a soil that’s going to be used for a period of time it, it lasts a lot longer, it gives you a lot more to work with and really create, and I’ve always seen the health of the plant just was so much stronger using a coco fiber base in comparison to a Peat Moss base.

And then obviously when you’re talking about switching over to big ag, I think a lot of the innovation that’s come from the cannabis industry is continuing to change big ag on so many different levels, whether it’s biology, whether it’s building medium, whether it’s changing the way we look at the word organic and the cleanliness of the products that we’re supposedly growing our food supply in. That’s something that’s always made me really proud to be a part of, is to see that day-to-day change in something so important, like growing food.

Mike: I think it’s really interesting, Rick, that you pointed out your first exposure to coco was from Dutch cultivators over in Holland. It was really in the ‘40s that a Dutch person agronomist stumbled on coco fiber and started pointing it out as a potential peat substitute or peat replacement. And it was in the ’40s and he’s like, “Wow, this feels just like the peat,” but there were the salt issues. And the people didn’t understand the buffering, and the molecular science was a lot different in the ‘40s, especially in agriculture.

So it wasn’t until people started to identify the salts and learn how to buffer it, that it started to become viable as a cultivation medium. And that was kind of more in the late ‘80s or early ‘90s. And it was a hard press. And you saw, like you said, people in Europe using it in greenhouse and controlled agriculture, not necessarily like big field ag, like incorporating it into fields.

So that’s an interesting part of the question to me is, it works great for horticulture, for controlled greenhouses, for small containers, for things like that, but also like how do we get it to play a role in large scale ag and food ag and soil building, and regenerative gardening. And that’s where, as a starting point using a mix is where so many people are when they’re like, “All right, I’m going to put gardens in. I want to do sustainable gardening, but I’m starting from scratch.” And they go buy a bunch of soil and they dump it and then they start treating it. Well, it’s going to provide longevity and functionality and be great for those home gardeners or mid-scale gardeners building beds and building gardens, but that doesn’t translate to being effective at field agriculture. And I think that’s been a hurdle for coconut fiber in general, is how do we get it into the fields to add a high lignin organic matter, which is really what it is and what creates its benefits.

So, I don’t necessarily see it being effective at large scale field ag, but I see a homogeny of traditional large-scale agriculture and greenhouse horticulture moving forward for facing the food shortages and the population expansion we’re facing right now. So, you’re going to see a much more hybridized model of cultivation moving forward, where we can’t dedicate tens of millions of acres everywhere to grow enough food for everyone and have it be effective. So you’re looking at higher concentrations of domestic, urban farms, closer to the places of consumption where people are looking for high output grows at a larger scale, which is where cannabis comes in, right? We were all growers in 2-light, 3-light, 5-light scenes having to maximize everything at a micro scale, and that’s where a lot of the developments in modern ag are coming from is, “All right, we have to be efficient at a scale this tiny. Now let’s blow that efficiency up to rows and rows of greenhouses, but keep that efficiency at scale.” And I feel like that’s our solution to feeding the world and that’s where coco becomes such an integral part of the future of food farming.

Dana: For sure, yeah. Growing all those basement tomatoes and maybe feed the world here in the future, huh?

Mike: Yeah. There’s a reason we make Basement Mix.

Reed: Yeah.

Reed: Yeah, back to the Dutch thing you guys were talking about and coco coming from over there, it’s like, I’ve been to quite a few farms were like Dutch flower farms that were out here that were doing flowers and then got into cannabis and just switched over their greenhouses from large scale flower farms that produce for places like Albertsons and stuff to then cultivating cannabis in those facilities. So, have you guys worked with many farms like that, or similar situations that you see coming from outside the industry into cannabis and just switching over and seeing what they can do?

Rick: Sure, absolutely. Obviously because of the dollar value, cannabis is always going to be a new and exciting venture for a lot of farmers. Typically, farmers struggle. It’s not an easy life and unless you’re subsidized by the government, it’s a gamble. You’re getting up earlier than everybody else, usually staying up and working later than everybody else and the pay isn’t always guaranteed. We do have a few areas here in California. Obviously, California is pretty big on the main stage when it comes to agriculture in general, but we definitely have a few areas here in California that were known for flower production, very similar to how they were doing it over in Holland and up until NAFTA, those areas were booming and when NAFTA was signed and they all headed south, there’s just full towns, millions of square foot of greenhouse that have been dormant basically since the ‘90s. So, we’re seeing a ton of those being taken over and turned into cannabis farms.

The climate’s actually pretty good, the counties have always been on board in understanding how to allow big ag to operate. So, in a lot of ways, and it’s unfortunate for places like the Emerald Triangle because they almost have a leg little leg up when it comes to that. They’ve already considered main ag areas, they’re definitely flat, they’re low lying, they’re in traditional flat land farm areas where we we’re up here where all these legacy growers are. And it was a wonderful thing when we were hiding and going gorilla. When you come to the light into the mainstream, unfortunately a lot of these amazing growers find themselves on rural property so far tucked back outside of civilization that it’s going to make it even that much harder for them to compete in a market.

Mike: Yeah, we don’t have the infrastructure or the accessibility that a lot of those places in Salinas and Santa Barbara that they had because they were cultivating for the cut flour involved industry at a scale. And it’s really impressive to go in and see some of these facilities now converted, rehabbed, and brought into cannabis cultivation. You’re seeing massive, massive grows in retrofitted facilities that are doing a really great job with it. But yeah, it is a threat to the small mom and pop farmers that were forced into hiding and to develop it four hours from the nearest town in the middle of the woods, surrounded by trees that you have to have a four-wheel drive to get to avoid enforcement.

Dana: Yeah, all the logistics stuff that made it a good place to hide makes it a bad place to ship from or get people too or whatever, right?

Rick: Yeah, we know that better than anybody. The soil company in the Emerald Triangle, it’s got its challenges for sure. It comes down to a quality thing too as far as when you’re dealing with the market, until farmers can actually put their product across state lines, it really creates, that’s the challenge. When you’re coming from big ag big farm production, obviously there’s going to be a quality difference, especially in comparison to what we’re doing here in the Emerald Triangle, where quality is always roomed superior. So, the California market may not support what we’ve got going on right now with these mega farms that are a lot of times just really creating and producing for extraction and whatnot. Until we can actually move product outside of California, I feel like it’s going to be a little bit of a struggle for the Emerald Triangle growers.

Reed: What states are you guys looking at right now? I know I’m up in Southern Oregon. I’m in Grants Pass, so I’ve been seeing trucks cruising up the five with pallets of you guys’ soil. I was over at endless summer a couple months back and chatting with the guys over there, they had a lot of good words to say about you guys. What other states are you guys looking at? What are you guys seeing? I know you guys look back…

Rick: Well, as far as soil goes, we’re nationwide. We’re distributed. We’ve got several distributors that really help us expand our network. We’re in all 50 states and beyond. We’ve had customers as far away as go as Guam, Costa Rica. So as long as our distribution network allows the product to go there and the customer’s willing to pay a little extra price, obviously logistically, then we’re pretty much just about everywhere. There are a couple of components of our soil that for ag purposes when you’re going into another country that that may limit us. Aged forest product that we make, that’s definitely one that keeps us out of Canada for the most part.

Mike: Yeah, and it’s really interesting because while we’re available nationwide, those logistics issues that we were just talking about really face us down hard in being competitive with products produced in other places. So we’re actively in the process of establishing an east coast manufacturing facility. So we’re going to be manufacturing somewhere in the Carolinas, getting product out there at a better logistical price point. And it’s been a huge challenge to overcome the differences in materials available there versus here. And it’s been a multi-year process again of analyzing what’s available there and how do we match it to what we do here. We’re not going to be the company that just makes a different product on the east coast like so many of our competitors have done, and they’re like, “Oh, well, we’ll call it the same thing, but we’re going to make it with pine bark and this and that.” And it’s just not the same.

And you saw when a lot of people launched those products that people who had been using it for years were like, “Oh, well, now I’m buying it and it’s a totally different, I have to change my entire cultivation regimen. My fertilizing, my watering, everything has to change because this medium in the same bag I bought two weeks ago is now completely different.” So we’re working really hard to make sure that we’re not contributing to that issue and making a product that’s consistent from coast to coast, even though we have to use slightly different products to make it.

So that’s been a fun and exciting challenge working with soil scientists and doing all sorts of grow outs and analyzing different components and working with really, really amazing people to change the narrative on how we produce soil compared to what they’ve been doing traditionally in east coast soil manufacturing. So we’re coming at the east coast and really the entire Eastern half of the United States pretty aggressively in the coming year plus to get a consistent product that we’re proud of at a better price point because of those logistic costs.

Rick: Yeah, and it’s interesting too, because you would think that it probably wouldn’t matter. And I know some of the first companies that probably make that transition to start producing on the east coast probably didn’t think it would be an issue. But as you see as these MSO’s come online and there’s a lot of people coming from states where they have been using product for years and years to the level where they’ve become so comfortable in understanding every nook and cranny about it, when they do set up shop in a different state, as that state comes online, all of a sudden, it’s become very important that that product is consistent and pretty darn and close to how the customers have become accustomed to use it.

Dana: Where do the source materials come from? You mentioned like the quality of the material and all that, where do you source materials from, the root materials?

Rick: Well, we source coco from India and Sri Lanka predominantly, and there’s a few other nation producers, but consistency, quality, and output are low. So we focus on best quality and consistency. So we have to reject less material, of course. So the coco that most of the world uses is coming out of a really pretty limited source. So we use that just like anybody else, but we do in-house buffering and control of the quality. So that’s a little different.

But as far as other components go, a decent portion of most soil products is forest material. We reclaim redwood from the logging industry, all second growth, sustainable harvest forest material. And we take the sawdust, the waste, things that would be burned or waste products that they’re looking for solutions for. And we compost it, age it in a way that makes it an effective soil material, of high lignin organic matter, that’s super effective and super awesome.

Well, that was our challenge. When we started looking east, there’s no redwood outside of California, really, maybe a little in Oregon, but outside of California, you just don’t have that redwood. So, we looked through a wide range of species blends, independent species and tried to apply our aging process directly to them to get something that was going to fit. And we’re also looking at sourcing, where can we get a source that it’s already byproduct of other industry? We don’t want to contribute to any additional deforestation, anything like that? We just want to improve efficiency of use of the commodities coming out of these processes.

So, it took us a while to identify a blend of species and a source that was consistent and then have it fit our process or alter that process just slightly enough to make it consistent. And so then, like I said, that’s been a wild ride, but we have identified some renewable sourcing that fits our needs out of the Carolinas, really all along Appalachia there and the Eastern foothills of Appalachia leading down to the east coast that we can access enough of this material as a byproduct from existing industry to create something that matches our product really quite remarkably.

And part of the challenge was convincing everyone out east that this made sense. Like, “No, we want to do it differently,” and everybody’s like, “Oh, no, you use the pine bark, you do this, you do that.” This is what we do out here. And I’m like, “But it’s not what we do.” So, it was a big learning curve. And we always try and use reclaimed, recycled, and sustainable items. So, waste from the fishing industry, shrimp meal, fish bone meal, crab meal, oyster shell, things that are being produced as a byproduct of our food sources and things like that. Those are available both on the east and west coast. So it’s just about narrowing or sourcing to match and get the recipes just precise to match what’s east and west so that people won’t be able to tell a difference.

And there will be clues on the bag and accessibility to the product information so people will know what they’re getting.

Reed: Right. Are you guys mainly focused on bags or do you guys do bulk as well, or what’s kind of the deal with that? What direction are you guys trying to head…

Rick: We definitely encourage bulk. We do a lot of bulk here in the Emerald Triangle where it’s logistically efficient and it makes sense. Once you get out of probably a four- or five-hour radius from our facility, it just makes sense to get bags. You’re getting more yardage on a truckload. There are facilities, especially as we become more directed towards big ag style of gardening where potting machines are available and there’s farms that have hoppers and forklifts and all the necessary equipment to handle totes, we can then ship totes of our soil, which still it limits us a little bit on the east coast. I know from where our facility is, when you start looking at Eastern Washington or Arizona, New Mexico, it still starts to get a little bit more on the expensive side where traditionally it seems like farms will stick with the bags mainly because of storage. The way that those are produced, it allows you to maybe store them outside or just have a little bit better coverage than the totes. We’ve always encouraged it though.

Mike: Yeah, we love to push the bulk and it really has become totes that have taken a lot of the bulk business because of those logistic concerns. And also, most users of a bulk product have some issue in how they’re going to handle that material. You either have to have a piece of heavy equipment, a front-end loader, or an excavator or something to scoop and grab and move lose soil in an effective way at scale. It becomes hard. And that’s where you see people using bags because they can pass them around and move them more effectively and grab them from a central point and move it to the planting sites. And that’s where the totes are a great middle ground, because you can move it with a forklift, you can grab it, you can hoist it up high to dump it into a hopper for potting machines. You can run it in the forklift over the top of the bed to add material to beds. You just have a lot more flexibility in the handling of the material. So, we do see a big push towards hybrid packaging. It’s loose, it’s bulk, but it’s also still packaged in a pallet size container.

Dana: Yeah, it seems like a nice solution. Is that something that’s been in the soil industry for a while? I saw the totes this morning and I thought of super sacks, and the first time I saw that was hemp. Does that go together or was it already in soil well before that?

Mike: It was in soil for professional mixes, from a lot of the big peat suppliers who were sending toted material to professional growers that are going to grow your geraniums and your mums and things like that that you’re buying in flats and stores. So these professional growers would order a truckload of totes and put it in and start their seeds and their nurseries and sell them through their retail. It wasn’t really a big part of a retail chain or of cannabis cultivation really until the last 10 years. And I’d like to think we were honestly on the forefront of that. We were pushing it before most cannabis type home professional grower type mediums were offering it. And it really made a huge difference. And our one-yard totes, it’s like a 200-gallon pot. So people were growing right in them. So, instead of buying bags and dumping them all into 100 gallon pots now people would be like, “I’ll take four truckload of those totes, load them with forklift on the field or tractor,” and they’re like, “Wow, I saved of tens of thousands in pots and labor.

Reed: Yeah, I see that with the bags sometimes too. Some guys just throwing bags in greenhouses. Do you guys ever get that with your bags?

Rick: We do. We have a three cubic foot plant in bag. It’s basically a 20-gallon grow bag. And those are really popular for greenhouses. Obviously, in the white market, the legal market, where labor, especially in places like California, it’s definitely not cheap. So those are the costs that you’ll see a lot of these facilities trying to get on board with anything that’s going to cut down on some of your labor, the ability to have a greenhouse harvested cleaned out replanted and a little to no time at all is definitely the win when you’re up against a battle in the marketplace. All those efficiencies make a big difference at the end of the day.

Mike: Not buying pots, not spending the time cleaning, not the giant filling the pots. And it was interesting because a lot of people were like, “Why would I buy these 20-gallon bags, they’re more expensive.” And we’re like, “Well, factor in your labor costs and all of these other pieces for a run and take a look at what that cost is going to be and come back to us.” And people are like, “Oh wait, we’re saving 7 to $10,000 in labor alone, let alone the pots and all the ones that break and have to be replaced each time.” So, it really is a very efficient way of cultivating.

Rick: I think in the cannabis industry too, there’s been money there and I feel like it’s led a lot of grows to conduct themselves without managing and collecting data and understanding their cost and what it costs to actually create a pound of product. And as we get more and more and deeper and deeper into this, people are starting to look at those things like labor and realizing, “Wow we could definitely make a huge difference for the longevity of our business, if we just would just start to think about that.” And I know it’s creating jobs and securing jobs and keeping money in the economy locally, obviously, it’s a super critical thing for any economy. But when it comes to farming, it’s always been something that’s been, those innovations in big ag farming and creating product, it’s always been something that you have to look at. And if you don’t, you’re facing an uphill battle.

We recently, I had a customer, not that long ago who had been using our product for a long time, and with the amount of product that they were going through, the conversation of totes had come up year after year. And they just shut it down. It didn’t make any sense to them, price is the price, and they really didn’t make much of a difference after the, the logistical end took its chunk out. To come to find out years later that they actually do, they’ve had a hopper and a potting machine and they literally, for years, have paid people to take these individually wrapped bags of soil up on ladders, dumping them into their hopper. Before they realized, that hopping part is literally what’s been done in this entire time.

Dana: Yeah, I think for better or for worse, that’s what happens with the industry, right? It’s like there was a lot of money in the legacy days and a lot of inefficiencies and now those are starting to get squeezed out. And so, you’re seeing that. We see that fight all the time with the trimmers too. It’s like, “Why do you… I like my staff, I like employing people and we like that too, but it’s hard enough to find good people now. So, we don’t think you should have them doing like menial jobs.” And yeah, if they feel like they’re higher valued employees and they don’t have to empty individual bags into the hopper, they’re probably going to be sticking around a little longer.

Mike: Well, it’s the classic argument of, “Oh, automation is taking my job.” Well, typically, that’s not really the case. It’s creating better jobs that allow a better scale up that’s more efficiency and allow producers, cultivators, whatever industry it is, a higher ceiling of actual production, so they can bring more people on, so they can expand the business beyond what their limitations would be if they were dependent on a strictly human workforce. And especially like you’re saying in the legacy farms, there was money, but there was also a really interesting dynamic where you had big pushes of labor on the farms. So you really needed to have your team in place for those big pushes of labor. So you’d have 3, 4, 5 guys living, working on the farm, and they wanted to keep those guys all year so that they had them for the pushes so you’d find jobs for them.

And it was like, “Oh, why would I buy totes? I’ll just let these guys hop the bags around. They’re going to be out there anyway. I’d rather have them be busy than sitting around drinking beer and not working between the pushes.” And now it’s like, “I can’t afford to have five people live on my farm year round and pay them and pay for their food and pay for their beer.” So, it might be more organized for the push, limit the labor that’s involved in those pushes and get some efficiencies. So, it’s just a completely different school of thought than it was for all of us who were cultivating in the legacy days. And really just like, “All right, let’s post up on the hill for seven months, we got to be here during harvest anyway, so let’s do it.”

Rick: We saw that big change too up here in the Emerald Triangle where I think a lot, in the ‘70s and ‘80s, and even in the end of the ‘90s, even some of your bigger producers of outdoor and greenhouse cannabis, it wasn’t something that was a rushed project. Back then storage and trimming your harvest over months and through the winter was a big thing. Nobody was really… Not many people were coming up here for ginormous boxes, hundreds of pounds at a time, it was just something that you would trickle out and create your salary throughout the year over the month.

So, it was quite a bit different than in the 2000s and late 90s or early 2000s, when we really started to see a huge push up here, whereas the demand for trimming became more of an issue, which led to really outsourcing, all of a sudden became an enormous thing here for people from other countries to come here sometime in August. A lot of times it was conveniently right after burning man and our streets would be filled, parks would be filled and everybody would be out there for work. And it was interesting for the conversation or the argument locally that, “Oh, they’re taking all the jobs from locals that had been trimming for years.” Well, the scale up that had happened with cannabis, there was just no way to keep up. And a lot of people here were affiliated with their own kind of successes, whether it was in the cannabis industry or not to kind of fill that void. So then what you just wind up having a lot of the local money instead leaving the area or you’re hiring 30, 40 people for two months from another country and then you’re paying them and then they’re taking their money back home with them, so not staying in your local economy, which is, hence the intro to the trim machines. That was definitely a big thing. Obviously, with that scale up, there was no way to really keep up with doing it by hand at that point.

Mike: Yeah, there was a time period where you could go to the local Plaza in Arcata down Square and roll in, post up, and walk around for a few hours and find a few people to drag back up to the hill. And it was no problem. You could fill those roles and there were people coming to do it. And that scale of cultivation outpaced the trimming staff, even with all of these trim-immigrants, we affectionately call them here. And that’s when people were like, “Screw it, I can’t even go down to the Plaza and find somebody from Italy to come trim anymore, I’m buying a machine.”

Rick: It also became very competitive. You’re up against every one of your neighbors and every one of the neighboring mountains to try to secure your trimmers, even to come back the following year and keep coming back year after year. There’s perks, everybody was offering vacations to Cabo for whoever did the most. I found myself cooking organic meals three times a day, making sure that everybody had a soft bed to sleep in while others were sleeping in tents or in the back of their cars. And that was how you had to fight to lock in those trimmers to be able to get some sort of loyalty and be able to get your product trimmed on time.

Mike: And friends stopped allowing friends, other cultivators to come to their harvest time, soiree and trim. They were like, “No, you can’t come to my trim circle, you’re going to steal my trimmers.”

Rick: You’re going to start poaching.

Mike: And it would be like, “Hey, where’d Jenny go?” And you turn over next door and you’re like, “Oh, hell no, you stole my trimmers again.” It got heated and neighbors would be fighting over trimmers and people to lead the crews, and it’s kind of funny in retrospect to look back.

Rick: And that goes with price too, obviously. Some people were paying 150, there were others that were paying 250 to 300. A lot of that had to do with how rural or how far that dirt road was to get there.

Reed: Yeah, 200 a pack of spirits and some IPAs.

Rick: I guess that too. “You think we can drink and still go to work?” “Well, sure. As long as you keep working.”

Dana: I don’t know, can you?

Reed: Yeah, so back to soil and stuff, we saw that, Dana mentioned that it looked like you guys were moving to amendments. Is that something that you guys are going to be coming out with in the next… When will that be?

Rick: It’s out.

Reed: It’s out?

Rick: Yeah, it’s out now.

Reed: Okay. Right on.

Mike: We’re super excited, literally, over the past couple weeks the first of our distributors have brought in our Crown Jewels, organic dry amendment products, bloom and grow. It’s CDFA organic input material approved and armory listed organic input as well, so people can use it for organic farming or gardening of any type, whether they’re certifying or not, it’s an organic input ingredient. And it’s a unique product because we micronized a lot of the components. It’s not a micronized product completely because not everything is broken down to those fine micron levels specifically because we wanted to break down at different rates. Things that break down slower, we milled smaller, things that broke down faster we left bigger so that we had a better balance of release based on the plant’s needs.

And we could control that fertigation window a little better with the product saying, “Okay, if you apply it now, it’ll have worked through all of these ingredients in about two, two and a half weeks, because they’re all milled to spec to allow that to happen.” Because you see a lot of these times when people are using organic dry amendments, it’s like, “Okay, well, I do a big amendment before I plant, get everything restarted, re-amended. And then I’m going to have to add my bat guano again in three weeks, I’m going to have to add my mineralization pieces every about four or five weeks,” like alfalfa and nitrogen things, you have to add a little more often. So, we wanted to homogenize it again to streamline the labor, save money on labor, and being more effective and create a universally applied single source amendment. So, you scoop out a one bag, it covers all of your needs, all of your micros, your NPK, to a point where you have sufficient nutrition, and then you can account for any specificity of your individual crop or circumstance with a little additional supplementation, right?

Like, “Oh, Hey, I need more nitrogen than the normal at my site because I have a higher carbon rate and it ties up.” Great. You can add a little bit of extra nitrogen in those feedings. That’s easy. It allows somebody to customize a mix very quickly and easily by just adding one component instead of having to change everything along the way. And it was really, it took us a long time to get to the point where we were happy with the amount of micros, the amount of N, P and K for both the grow and bloom formulations, because we felt that the numbers needed to be a little different than a lot of the dry amendments out there. So you’ll see that when you look at our numbers, they’re a little bit different on the NPK than some of our competitive products, but it’s partly due to release times, and partly due to, we felt many of the dry amendments underserved, organic during the growth phase and then drastically underserved nitrogen during the bloom phase. And so, we wanted to provide that bloom window with enough nitrogen to get through your big height, push, get through that big vegetative matter push where you’re needing to create more plant material. And that’s one of the key nutrients for generating more plant material is nitrogen.

So, we just got a slightly different approach, but we’re having great success so far. People are really enjoying it. And it’s just starting to get out into the wide market with all of our products, because we are where we are in Humboldt. We can serve it out to some local community members for field trials, things like that. So we’ve sold tons and tons and tons, literally of these amendments already to farmers who have been successful with them. It allows us to get a better beat on what our customer feedback’s going to be before we go to greater market. So we’ve crossed that hurdle, we feel super confident in the product, and now people can go into their local hydro store or garden store and ask for it and the distributor will have it ready to order. So, get out there at home and ask for Crown Jewels.

Reed: Right on. Awesome.

Dana: Relative to that, how… Reed and I were talking earlier about New York’s coming online, the hemp farmers getting grandfathered in there. It’s pretty cool. But for those newer to the cannabis market, looking at all the different options for soils, what’s some guidance in terms of them just understanding what, because a lot of them have similar pitches, so how do you differentiate or how do they, me, if I’m a new grower, how do I understand what I should be doing or what I should be evaluating in the soil?

Rick: I always say that coming from where we’re coming from, a community of growers, if not growers ourselves, the standard that we’re held to is quite a bit different. Our customers are our family, they’re our friends, they’re our neighbors, our teachers, so it’s critical for us to come out with product that’s consistent, that our customer service is on point so that we’re walking through our customers through the process, giving them the best chances of success. So that’s something I’ve always stood behind. And I always push as part of the biggest component outside of actual product consistency is the standard and the care, the compassion or passion that we put behind what we do. It really does separate us. I feel like a lot of companies get off the hook in that regard. They’re a business, they’re selling product. With us, we rise in the morning and live all day and go to sleep with this industry and cannabis and our customers on our minds constantly.

Mike: So, one thing that I echo that it’s all about the quality and consistency and that’s what you want to identify to start from. But because also of our community, there are so many different styles of cultivation. Everybody’s growing in a different way up here, different hills and different neighborhoods have different styles, so it’s very difficult to be like, “Oh, you want to grow in this mix like this.” So personally, when I’m talking to somebody who’s new or somebody who’s scaling up at a level they’re not used to and looking to come from a new angle and looking for input, I say, “Identify how you want to grow. How often do you want to water? How are you going to apply your water? How do you want to food? How do you want to feed? How are you going to apply that food?” Look at all of the components that you’re going to have to understand going into it.

If you’re a small home grower and you’re going to be mixing up a five-gallon bucket of fertilizer and watering by hand, your needs are very different than somebody that’s growing 300 lights and wants an automated system because they can’t physically water with a hose or a watering can fast enough. So those pieces are super duper important and understanding what medium’s going to fit your needs best and what fertigation type process is going to fit your needs best.

And so, we have mixes that are running the gamut from straight pure coco fiber to a super heavily aerated soilless blend called Tupur, and that really has driven the 70/30 soilless movement in a big way. It’s designed for people to water often and aggressively. That’s not a super effective medium for people hand watering. Because you’re going to be in there every day or every couple times a day, depending on your plant and container size. So, if somebody’s at home hand watering, I’m going to say, “Try our Kings Mix, it’s very versatile, it’s going to give you an idea of what you want to do, whether you want to move to something that dries a little slower, so you’re watering every third day or move to something like Tupur and put a dripper or some sort of automated delivery system to your fertigation. So you don’t have to mess with standing there mixing a reservoir and applying it by hand, you’re spending that time playing with your plant while you make sure your drippers are running.”

So, it’s all about identifying what’s going to fit your needs for the rest of your grow first, and then finding a medium that fits those needs. And that’s why we feel like we stand out because we have a medium that fits more needs more effectively than most other companies.

Reed: Awesome.

Rick: Yeah, we keep it pretty simple. We’ve got five mixes total. We’ve got our straight coco like Michael had mentioned, the Tupur which is basically our flagship product, it’s definitely put us on the map over the last 10 years. Kings Mix is our newest, it’s only been around, what are we talking here? Six, seven years maybe. That’s quickly become our number two powerhouse as far as sales go. Basement Mix and Mendo Mix, they are two original mixes. They were designed more for outdoor and less frequent watering. They both come with an amendment charge. Mendo Mix being the heavier charge.

So we keep it very simple. And I think in doing so, we give the customer a pretty good overall, “Hey, this is going to be a medium that I can work with and tweak.” And if you decide after using it once that you need to go a little bit in one direction out of the other, you can easily pivot. Whether if it’s from Kings Mix and you want more drainage, you pivot down to Tupur. If you’re looking to water a little less, then you’d move step up to Basement Mix. And yeah.

Dana: Very nice. Well, good. I think we’re out of time here, but thank you Mike and Rick, both for joining us today. I really appreciate the conversation and education in a lot of ways too. So, if anyone wants to reach out to you guys and find out more, what’s the best opportunity for them to do that or a way to do that?

Mike: Well, we’re all over social media, you can find us @royalgoldsoil is our handle for Facebook, Twitter, Instagram, all that stuff, @royalgoldsoil, you’ll track us down. www.royalgoldcoco.com is the website. And you can also check us out on our podcast, as you guys mentioned earlier, Royal Grown Radio. So we’re @royalgrownradio on Instagram and all the social, www.royalgrownradio.com on the web, and we’re very thankful for the opportunity to come and sit and share some knowledge with you guys and look forward to another opportunity to share some of your knowledge. So, thank you.

Reed: Yeah, thank you very much.

Rick: Thanks a bunch, you guys. I really do appreciate sitting down and getting to know you guys too.

Reed: Yeah, likewise. Well, thanks so much for listening to the Own Your Harvest podcast, powered by Triminator. If you enjoyed this podcast, please subscribe to the show and share it with your fellow growers and farmers. Thanks guys.

Dana: Take care.