How to Dry Bubble Hash: A Comprehensive Guide

As solventless concentrates continue to gain popularity (for instance, rosin sales have doubled between January 2021 and January 2023), bubble hash is quickly emerging as a valuable opportunity for commercial growers. Revered for its purity, flavor, and potency, bubble hash is produced by separating trichomes from plant material, and a key step in making bubble hash is the drying and curing stage.

The trichomes in cannabis plants are full of cannabinoids and terpenes, giving them their unique qualities. Using ice water and gentle agitation, commercial growers can carefully separate trichomes from flowers in a process known as ice water extraction, a form of solventless extraction. There are many factors involved in producing high yields of ice water hash, from the agitation and washing method to the equipment and materials chosen.

Professionals must carefully select premium buds with the highest concentration of trichomes to create the most potent and flavorful product. However, it’s also important to ensure the concentrate is dried and cured correctly to preserve its unique qualities.

In this blog, we share everything cultivators need to know about the importance of properly following the steps to dry bubble hash and some of the best methods available.

Preparing to Dry Bubble Hash

Drying bubble hash is one of the most important stages in the solventless extraction process. It has a direct impact on the final potency and flavor of the product. To achieve optimal results, growers must carefully prepare the drying environment to ensure the terpenes and cannabinoids are preserved. Creating the ideal environment starts with a focus on cleanliness and low humidity.

Before the drying process begins, producers must select an environment that is free from any contaminants that might affect the purity of the final product. Dust, dirt, and other impurities can easily stick to the hash, compromising its quality.

Additionally, a low-humidity environment is essential, as excess moisture around any cannabis concentrate can lead to mold growth and damage the structure of delicate trichomes.

Below, we have included a few tips for creating the perfect drying area for bubble hash:

Carefully Select a Designated Drying Area

Carefully selecting a drying area will help to enhance the quality of your bubble hash in numerous ways, by reducing the risk of cross-contamination, preserving optimal air temperature and humidity, and ensuring excellent air circulation.

The right drying area should have good ventilation, and plenty of space to ensure air can circulate around and through the product evenly. Proper air circulation prevents mold and helps distribute the air through the bubble hash evenly. (Pro tip: Consider purchasing an air conditioning system and keep your drying racks evenly spaced to support optimal airflow).

Notably, drying environments should be cool (around 55°F), and dark. Exposure to light and heat can cause chemical reactions which reduce the potency of your product. Make sure you can control the humidity levels as well, so you can minimize the risk of mold and mildew. A humidity level of no more than 35% is often recommended for bubble hash.

Use Drying Racks Effectively

Properly drying bubble hash generally requires the use of high-quality drying racks. These racks should be created with food-grade materials, such as stainless steel, to help minimize contamination and reduce the risk of non-compliance with GMP guidelines.

The racks also need to be spaced evenly, so that air can circulate around the product evenly, and create a more consistent final product. Avoid overloading trays with too much product and ensure batches are spaced out to minimize moisture build-up.

Since you’ll need to check on the drying process regularly, it can be helpful to invest in racks with wheels, as this will allow you to rotate the racks throughout the process and easily examine different batches whenever you need to. Make sure racks are thoroughly cleaned between batches to avoid cross-contamination.

Connect with an expert today.

Drying Techniques for Bubble Hash

There are various methods producers can consider using to dry bubble hash. Each option has its own distinctive pros, cons, and processes to consider. The right strategy for your operation will depend on a number of factors, including your specific preferences. For commercial cultivators, freeze-drying wet bubble hash is generally the best method because it’s quick and preserves terpenes better than other methods.

Here are some of the most common techniques used for drying bubble hash:

Air and Fan Drying

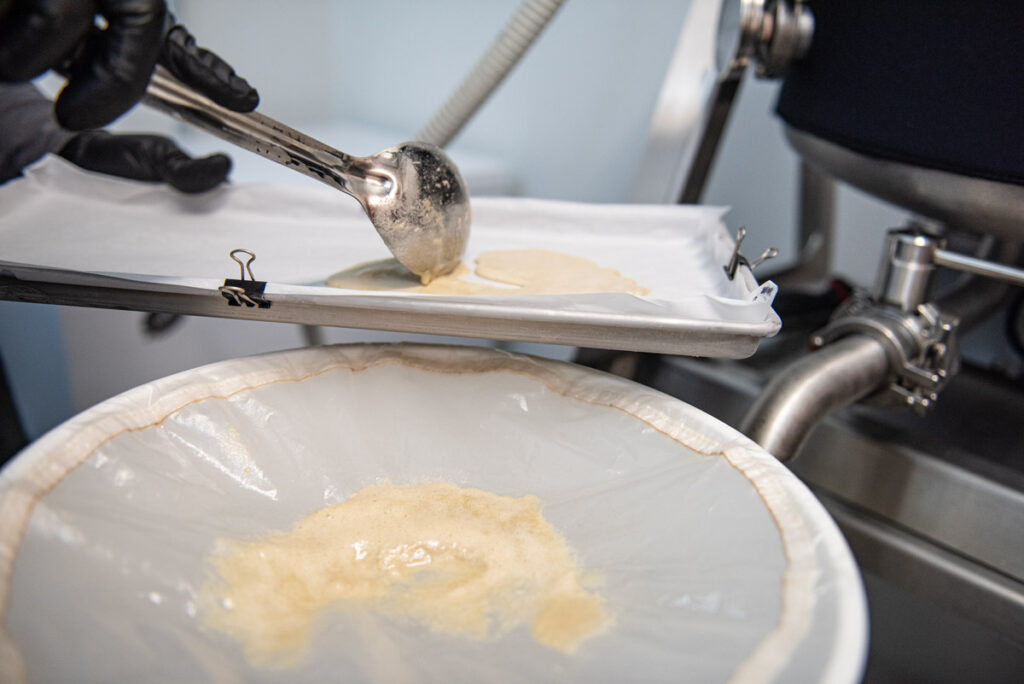

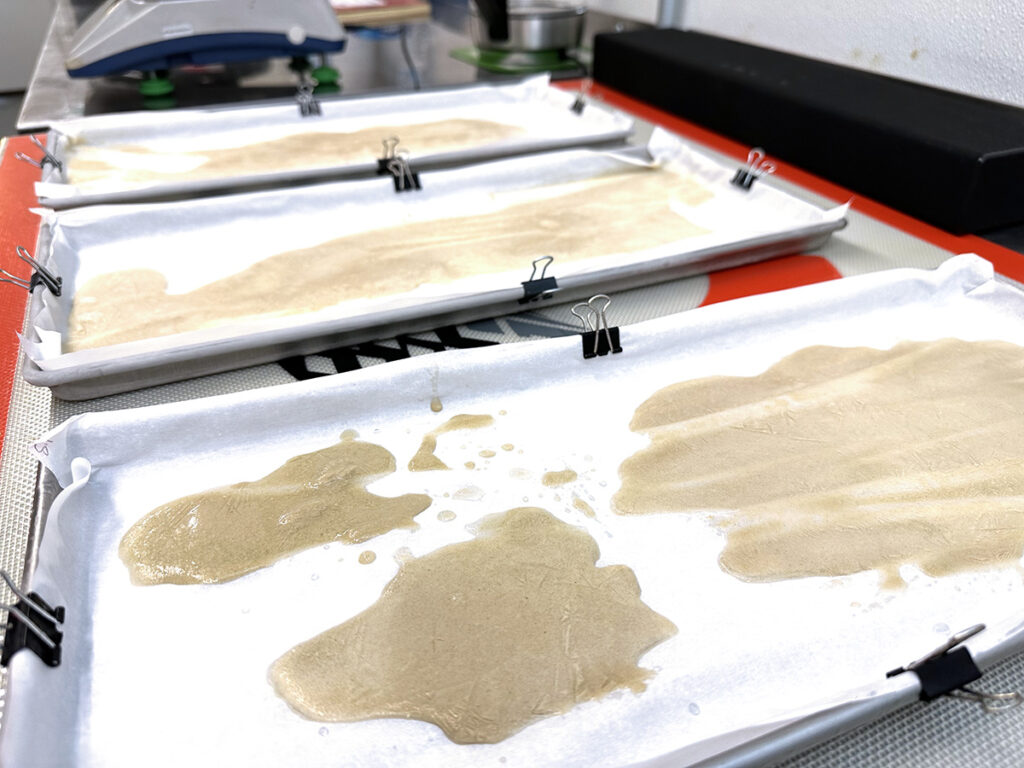

Air and fan drying are the most common, traditional methods used for drying bubble hash. The process involves spreading the hash out in a thin layer over a wide surface area, allowing any water to evaporate evenly through natural air exchange.

Fans, on low speed, can often help to accelerate the process, although this method does take a little longer than some other bubble hash production methods. You’ll need a well-ventilated room or designated drying area, as well as a fan to help enhance airflow.

It’s a good idea to ensure you spread the wet bubble hash out thinly and evenly to ensure uniform drying. Compared to other hash-drying methods, air-drying bubble hash is one of the most straightforward and easy approaches. It’s cost-effective and requires minimal specialized equipment.

Controlled Environment Drying

Controlled environment drying is similar to air drying. However, it often involves using an environment that allows for complete control over temperature and humidity levels. Most manufacturers create a cold room that maintains a consistent temperature of no more than 30°F.

The cold air in the drying room allows for a reduced risk of mold and over-drying. This can help to ensure the bubble hash’s continued quality. However, you will need special equipment, such as a hygrometer, to monitor humidity levels accurately.

Avoid high temperatures that could over-dry or damage the delicate structure of the trichomes and ensure there’s plenty of space available to allow air to circulate around the bubble hash.

Low Heat Drying

Low heat drying is a lot like controlled environment drying. It involves placing wet hash in a cool room and using small amounts of heat to help accelerate the drying process. In most cases, it’s best to target temperatures of around 55°F.

With low-heat drying, it can take between two and ten days for wet bubble hash to dry, depending on the volume of the product and the amount of space available for air circulation. You’ll need a carefully controlled environment, as well as fans and ventilation to reduce temperature and humidity.

This method can be an excellent way to preserve control over the quality of the finished hash, but it can take a little longer than other methods.

Freeze Drying

Few methods are more effective at preserving terpenes than the freeze-dryer method. Freeze dryers are specialized pieces of equipment that can rapidly dry out fresh bubble hash, in as little as 24 hours.

The freeze-drying process preserves high terpene profiles and the overall potency and flavor of the product. What’s more, it’s excellent for scaling production, as large batches can often be freeze-dried within a short amount of time. However, the equipment needed may be a little more expensive than other methods.

To make the most of this method, ensure your fresh hash is spread evenly on a tray before placing it in the freeze-dryer. Monitor the drying process closely to reduce the risk of over-drying.

Vacuum Drying

Similar to freeze drying, vacuum drying is another one of the best ways to preserve the quality and potency of the trichomes in your bubble hash. It involves using specialized equipment to reduce the pressure in the atmosphere and eliminate excess moisture from the wet hash.

You’ll need a vacuum drying chamber, with a vacuum pump that allows you to control the environment. Most of the time, you’ll need to monitor and adjust temperature and pressure settings carefully to ensure exceptional drying conditions.

Although this process can be expensive, vacuum drying accelerates the drying process, and promotes even drying for consistent, high-quality hash.

Monitoring and Testing Your Bubble Hash

Throughout the drying process, consistently monitoring your bubble hash will be crucial to preserving its quality. You’ll need to keep a close eye on various factors, including temperature, moisture content, appearance, and texture.

Monitoring the moisture content of your hash is crucial for preventing under- or over-drying, both of which can lead to losses in potency and flavor. You can check the moisture content by taking a small sample and squeezing it gently between your fingers to see if it crumbles. When bubble hash is dried properly, it should have a dry, sandy feel.

Alternatively, if the hash is over-dried, it may seem more like a solid brick in texture, as the resin will have hardened. Additionally, both over-dried and under-dried hash can lack luster and visual appeal.

Once the drying process is complete, you’ll also need to test your bubble hash for quality attributes. This means examining the potency and terpene profiles of your cannabis concentrate, as well as checking for any potential contaminants.

Laboratories can perform potency testing to measure the levels of cannabinoids and use terpene profiling to identify the aromatic compounds responsible for unique flavors and aromas. Labs can also test for microbial contaminants, such as mold and bacteria, that could lead to potential health risks. This testing is essential for maintaining quality at an industrial scale.

Finally, once you’re sure of the quality and potency of your bubble hash, you’ll need to ensure it’s stored properly after drying. Often, this means using airtight containers to prevent exposure to light, moisture, and air, which can degrade your concentrate over time.

Keep the hash stored in a cool, dark environment, free from temperature fluctuations and light exposure, and avoid humidity, as this can lead to mold growth. It may be helpful to clearly label your containers to ensure you can keep strains separate and organized.

Drying Your Bubble Hash Correctly

Bubble hash represents an exceptional opportunity for commercial growers, particularly as the popularity of cannabis concentrates continues to expand. However, to ensure you’re offering your customers the best experience, and preserving your brand reputation, you’ll need to adhere to the right processes for preparing and drying your bubble hash.

The drying process is a crucial step in bubble hash production. Its proper execution will directly impact the overall quality, potency, and flavor of your product. There are various methods available to choose from. Air drying, low heat drying, and controlled environment drying are all ideal for smaller yields, and companies with lower budgets.

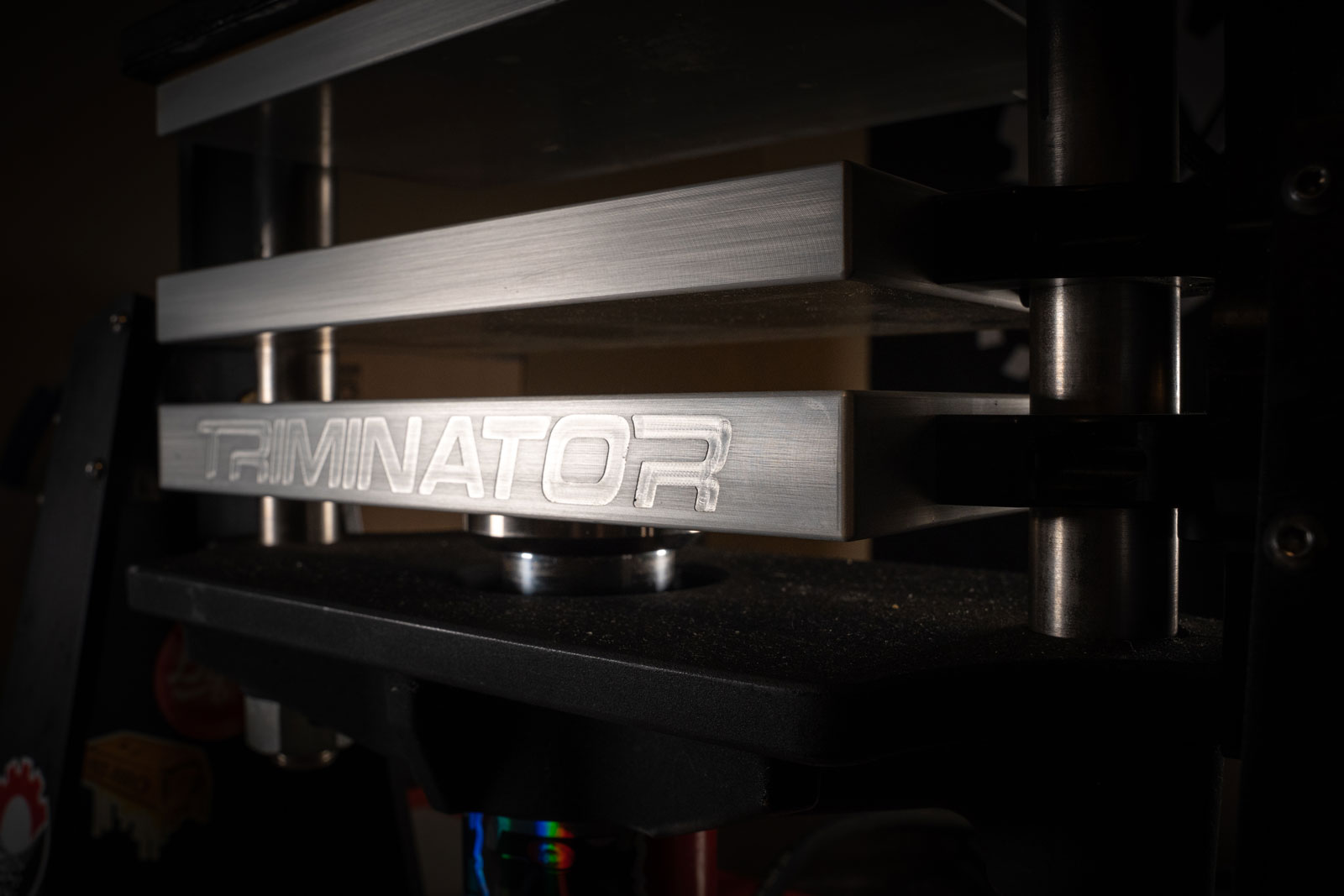

Vacuum drying and freeze-drying provide a more advanced way to scale the production of concentrates and preserve the quality of your products.

Learn more about how Triminator can help transform your commercial bubble hash production. With our products, you can improve the efficiency of your cannabusiness, and enhance the quality of your yields.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields