How to Make Rosin Carts: A Comprehensive Guide

The cannabis industry is undergoing a transformative shift, with solventless rosin cartridges emerging as a cornerstone of premium vaping products. Valued for their purity, robust terpene profiles, and potent effects, rosin carts are redefining consumer expectations. As vaping continues to dominate the market—projected to reach US$14.7 billion by 2030—extractors are seizing the opportunity to add this high-margin SKU to their portfolios. Triminator, a pioneer in cannabis processing equipment, empowers producers with cutting-edge tools to create rosin carts that stand out in a competitive market. This exhaustive guide provides a scientifically grounded, step-by-step process for crafting rosin carts, leveraging Triminator’s precision equipment to ensure unparalleled quality and scalability.

The Surge of Solventless Rosin Carts

Rosin carts have captured the attention of cannabis enthusiasts due to their solventless extraction method, which eliminates the need for chemical solvents like butane or ethanol. This results in a cleaner, more natural product that preserves the plant’s full spectrum of cannabinoids and terpenes. Unlike distillate carts, which often require reintroduced terpenes, rosin carts deliver strain-specific flavors and effects, commanding premium prices in dispensaries. The rise in consumer demand for health-conscious, high-quality vaping options makes rosin carts a lucrative addition for extractors. Triminator’s rosin presses streamline the production process, enabling both small-scale and commercial producers to meet this demand with consistent, professional-grade results.

Why Rosin Carts Matter

- Market Appeal: Rosin carts cater to discerning consumers seeking purity and flavor, fetching 20–30% higher retail prices than distillate carts.

- Versatility: They offer a convenient alternative to dabbing, appealing to on-the-go users.

- Brand Growth: Adding rosin carts expands product lines, enhancing customer loyalty among fans of existing rosin products.

- Sustainability: Solventless production aligns with eco-conscious practices, reducing environmental impact.

Triminator’s commitment to precision ensures extractors can capitalize on these benefits with minimal waste and maximum efficiency.

Crafting High-Quality Rosin

The quality of a rosin cart hinges on the rosin itself, which requires careful selection of starting material, precise extraction techniques, and proper storage. Triminator equipment plays a pivotal role in this process.

Selecting the Best Starting Material

The choice of starting material significantly impacts rosin quality. Options include:

- Fresh-Frozen Flower: Ideal for live rosin, preserving delicate terpenes for vibrant flavors. A bucker efficiently removes fan leaves and prepares buds for freezing, ensuring optimal trichome and terpene retention.

- Hash Washing: Produces clean bubble hash that can be pressed into rosin, perfect for carts. Use a commercial hash washer for fresh-frozen material to create high-grade bubble hash.

- Dry Sift Kief: Trim can be tumbled in a mesh screen to collect kief, then pressed into rosin.

High-quality genetics, such as strains bred for high trichome yield, are critical. Ensure material is cultivated with proper nutrients and cured at 55–62% humidity to avoid compromising rosin quality.

Extraction with Triminator Rosin Presses

Effective rosin extraction requires precise control over temperature and pressure. The Triminator TRP Stack delivers up to 25 tons of pressure with digital temperature controls, allowing extractors to press at 170°F–220°F for optimal flavor preservation. Lower temperatures maximize terpene retention, while higher temperatures increase yield but may degrade quality. For commercial operations, the Triminator Rosin Press supports high-volume production with automated features, reducing labor costs and ensuring consistency.

To minimize waxes and lipids, use the proper size micron rosin bags, which filter out impurities for a smoother, cart-ready extract. A pre-press mold can also help with extraction efficiency.

Storage and Preservation

Post-extraction, store rosin in airtight glass containers at temperatures below 40°F to prevent terpene degradation. Avoid exposure to light and air, which can oxidize cannabinoids. For large-scale operations, freeze-drying bubble hash with a commercial freeze dryer before pressing preserves terpenes and enhances rosin purity.

Advantages of Rosin Carts

Rosin carts offer distinct benefits that make them a standout choice for producers and consumers alike:

- Solventless Purity: Free of chemical residues, rosin carts appeal to health-conscious users seeking a clean vaping experience.

- Superior Terpene Profiles: The solventless process retains strain-specific terpenes, delivering complex flavors and aromas that rival dabbing.

- High Potency: Rosin carts maintain a full cannabinoid spectrum, providing robust effects without artificial additives.

- Profit Potential: Premium pricing and growing demand make rosin carts a high-margin product, especially for producers using Triminator’s efficient presses.

- Consumer Loyalty: Offering rosin carts alongside dabbable rosin strengthens brand loyalty, as customers can enjoy their favorite strains in a portable format.

Triminator’s equipment ensures extractors can produce rosin with the consistency and quality needed to meet these market demands.

Step-by-Step Guide to Rosin Cart Production

Transforming fresh-pressed rosin into vape-ready cartridges requires precision and attention to detail. Below is a detailed standard operating procedure (SOP) optimized for the solventless extraction process.

Materials Needed

- Fresh-pressed rosin (hash rosin preferred for lower wax content)

- Digital scale (accurate to 0.01g)

- Heat-proof, sealable glass jar (mason jar, 4–8 oz)

- Precision oven with temperature control (±5°F accuracy)

- Cannabis-derived terpenes (optional, strain-specific)

- Glass stir rod or lab-grade silicone spatula

- Glass syringe (5–10 mL) with blunt-tip needle

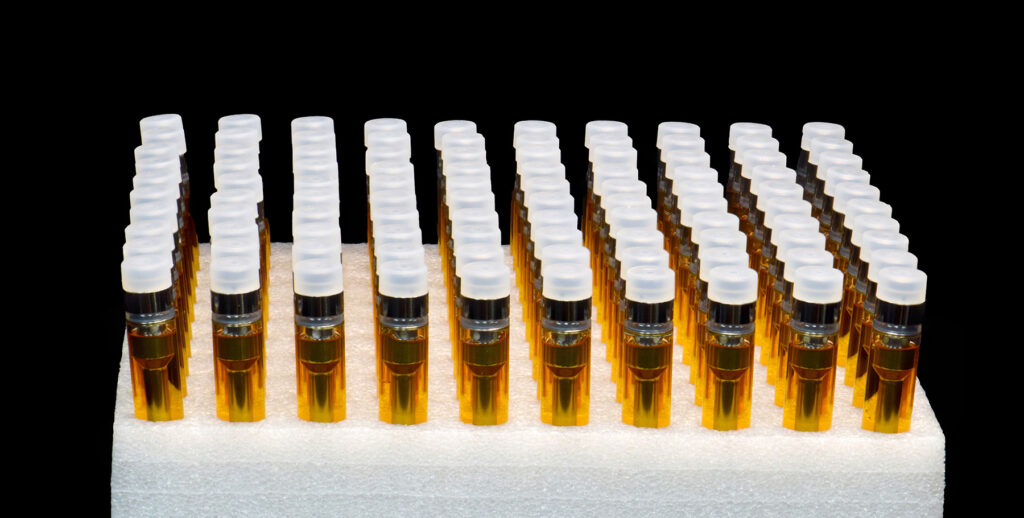

- Empty 510-threaded ceramic-wick vape cartridges

- Heat-proof vape cart tray

- Personal protective equipment (protective gloves and safety glasses)

Step 1: Weigh and Prepare Rosin

Using a digital scale, weigh the rosin to calculate the number of 0.5g or 1g cartridges needed. Place the rosin in a heat-proof glass jar, filling no more than halfway to accommodate expansion during heating. Hash rosin is ideal due to its low lipid content, ensuring smoother vaporization.

Step 2: Heat-Cure the Rosin (Jar Tech)

To achieve a water-like viscosity, decarboxylate and liquefy the rosin using the Jar Tech method. Seal the jar and place it in a precision oven set to 150°F–220°F (60°C–104°C). Monitor for 24–48 hours until no bubbles form, indicating complete decarboxylation and liquidity. Avoid opening the jar during heating to preserve volatile terpenes. For commercial producers, a rosin press’s consistent output ensures uniform rosin batches for this process.

Step 3: Add Terpenes (Optional)

If desired, add 1–2 drops of cannabis-derived terpenes per gram of rosin to enhance flavor and reduce viscosity. Use a glass stir rod to mix thoroughly until the mixture is homogenous. Terpenes can mimic strain-specific profiles to enhance consumer appeal. Skip this step for a fully solventless product.

Step 4: Fill the Syringe

Warm a glass syringe to 90°F (32°C) in an oven or on a heating pad to facilitate rosin flow. Draw the liquid rosin into the syringe, ensuring no air bubbles form. If bubbles appear, invert the syringe and gently depress the plunger to expel them. For large-scale production, automated filling systems can save time.

Step 5: Fill the Cartridges

Select high-quality 510-threaded cartridges designed for viscous oils like rosin. Slowly inject the rosin, filling to two-thirds capacity to prevent overflow. Avoid air bubbles by turning the cartridge or filling around the base of the oil tank first. If air bubbles persist, place the cartridges in a heat-proof tray and heat at 100°F (38°C) for 5 minutes to melt the oil down to the base of the tank. This ensures consistent vaporization and prevents clogging.

Step 6: Assemble and Seal

Screw the mouthpiece onto each cartridge tightly to prevent leaks. Test a single cartridge in a vape pen to confirm functionality before filling a larger batch. Use a heat-proof tray to keep cartridges organized during assembly.

Step 7: Let the Cartridges Settle

Allow the cartridges to sit at room temperature for 4–6 hours to ensure the rosin settles into the wick. If the rosin solidifies, repeat the heat-curing process for an additional 12–24 hours. Store finished cartridges at 60°F–75°F to prevent crystallization, which can clog the wick.

Step 8: Quality Control and Testing

Before scaling up, test a small batch for viscosity, flavor, and performance. Use a vape pen to verify smooth vaporization and consistent potency. Triminator’s precision equipment ensures repeatable results, minimizing batch-to-batch variability.

Expert Tips for Optimal Rosin Cart Production

To elevate your rosin cart production, consider these expert tips:

- Work Efficiently: Rosin can solidify quickly when cooled. Maintain a warm environment (70°F–80°F) during filling to ensure smooth handling.

- Precision Temperature Control: Overheating degrades terpenes, while underheating results in thick rosin.

- Start Small: Test a single cartridge before filling a large batch to identify issues with viscosity or wicking. This saves time and material.

- Choose Quality Cartridges: Ceramic-wick cartridges are essential for rosin’s viscosity. Avoid cotton wicks, which can clog and degrade flavor.

- Monitor Terpene Profiles: Use strain-specific terpenes to enhance flavor, but avoid over-dilution (no more than 10% terpenes by volume) to maintain potency.

- Clean Equipment Regularly: Residue buildup can contaminate rosin. Clean equipment and tools with a food-grade solution to ensure purity.

Scaling Up with Efficient Equipment

For commercial extractors, scaling rosin cart production requires equipment that balances efficiency and quality. The Triminator TRP Stack is designed for high-volume operations, delivering up to 25 tons of force with automated controls for consistent output. Paired with hash washers, buckers, trimmers, and kief screens for material preparation, producers can achieve industrial-scale results without sacrificing quality. These tools reduce labor costs, minimize waste, and ensure rosin meets the stringent standards of premium vape carts.

Triminator Advantages

- Precision Engineering: Triminator’s rosin presses offer unmatched temperature and pressure control, ensuring repeatable, high-quality extracts.

- Scalability: The rosin press supports large-batch production, ideal for meeting market demand.

- Material Preparation: Bucking, trimming, and milling equipment ensure consistent input material, critical for uniform rosin quality.

- Durability: Triminator equipment is built for long-term use, reducing maintenance costs and downtime.

- Support: Triminator’s expert team provides guidance on optimizing solventless extraction production, from setup to scaling.

Troubleshooting Common Issues

Even with the best equipment, challenges can arise. Here’s how to address common rosin cart production issues:

- Clogging: Caused by high wax content or improper wicking. Ensure thorough wicking at 100°F.

- Leaking Cartridges: Check for overtightened or loose mouthpieces. Use high-quality cartridges and test seals before filling large batches.

- Inconsistent Flavor: Overheating during curing can degrade terpenes. Maintain temperatures below 220°F and consider adding strain-specific terpenes.

- Low Potency: Ensure proper decarboxylation during curing. Test rosin for potency before filling.

- Solidification: If rosin solidifies in cartridges, extend the heat-curing process or store cartridges in a warmer environment (70°F–75°F).

Achieve Optimized Extraction Processing

Producing rosin carts is a meticulous but rewarding process that combines the art of solventless extraction with the science of vaping. By leveraging Triminator’s advanced equipment and tools, extractors can create premium cartridges that deliver unmatched purity, flavor, and potency. From selecting high-quality starting material to mastering the curing process, every step is critical to success. Whether you’re a smaller-scale extractor or a commercial producer, Triminator provides the equipment and expertise needed to excel in the competitive cannabis market.

Ready to elevate your rosin cart production? Contact Triminator to explore our full range of rosin presses, accessories, and tools. Let us help you craft solventless vape cartridges that captivate consumers and drive profitability.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields