How to Cold Cure Rosin

Learning how to cold cure rosin could be an incredible opportunity for growing cannabis businesses, particularly as demand for solventless products continues to grow.

As of 2023, the biggest solventless product within the category is rosin. It accounted for 14% of all dabbable dollar sales in January 2023. In certain mature markets, such as California and Colorado, rosin accounted for an even greater share of sales, 22% and 21%, respectively.

Curing your rosin is a surprisingly easy way to increase your potential profits with a range of new texture, potency, and flavor options. While there are numerous ways to cure solventless rosin, the cold curing process is often the most popular because it preserves terpene profiles and delivers a rich, consistent texture and flavor.

Today, we’ll walk you through the steps involved in cold curing rosin, and share our expert insights on how you can get the best results from your process.

What is Cold Curing?

Curing rosin involves heating or cooling your extraction in sealed glass jars for a specific period of time until it reaches the desired consistency and texture. Depending on your goals, you may also choose to agitate or whip the extract during the process.

Effective curing techniques allow cultivators and cannabis business owners to fine-tune their end product, transforming its texture and consistency into something more desirable and enhancing its overall flavor profile.

With cold curing, you’ll typically store your rosin in a controlled temperature environment between 40 and 70 degrees Fahrenheit. This type of curing works best with flower rosin, or live rosin, allowing for a rosin “badder” consistency, which is one of the most desirable consistencies on the market today. It also allows for exceptional terpene preservation, eliminating the risk of terpenes being damaged or evaporated by excess exposure to heat.

Rosin can also be cured at a warmer temperature, and heat-curing can allow for unique textures, like diamonds and sauce. It should be noted that warm curing, often at temperatures between 90 and 120 degrees Fahrenheit, can offer less stability and may lead to a loss of potency unless some additional precautions are taken to ensure a successful outcome.

Cold Curing Techniques and Variations

There are various approaches to creating cold cured rosin. The most common approach is to simply leave your rosin concentrates in a sealed glass jar at room temperature for 24-72 hours, until it achieves the right consistency and texture. However, you can also choose to keep your stored extract in a refrigerator, at a temperature of 40 degrees Fahrenheit.

While extremely low temperatures can damage the cannabis plant and the extracts you create, temperatures of around 40 degrees can help accelerate the curing process and preserve more terpenes. Storing your rosin in a refrigerator can help to ensure consistency in your batches, minimizing the risk of temperature fluctuations.

Once you find the right temperature, you can achieve higher levels of stability with your rosin, and maintain the same texture for all of your rosin concentrates from each harvest.

Additionally, while some growers prefer to leave their rosin untouched in the refrigerator during the curing process, others use intermittent stirring or “whipping” techniques to increase the stability of the rosin and achieve a smoother texture.

Some cultivators prefer to maintain cold temperatures throughout the entire extraction process, even before the curing stage. Ice water extraction is a popular method for producers who choose to keep the flower and process cold the entire time before pressing. This method of solventless extraction can help preserve terpenes in live rosin and enhance the flavor of the original strain, more than using other extraction techniques.

Why Cold Cure Rosin? The Benefits

While warm curing rosin has merits, cold curing delivers a variety of unique benefits for your concentrate.

Cold curing offers:

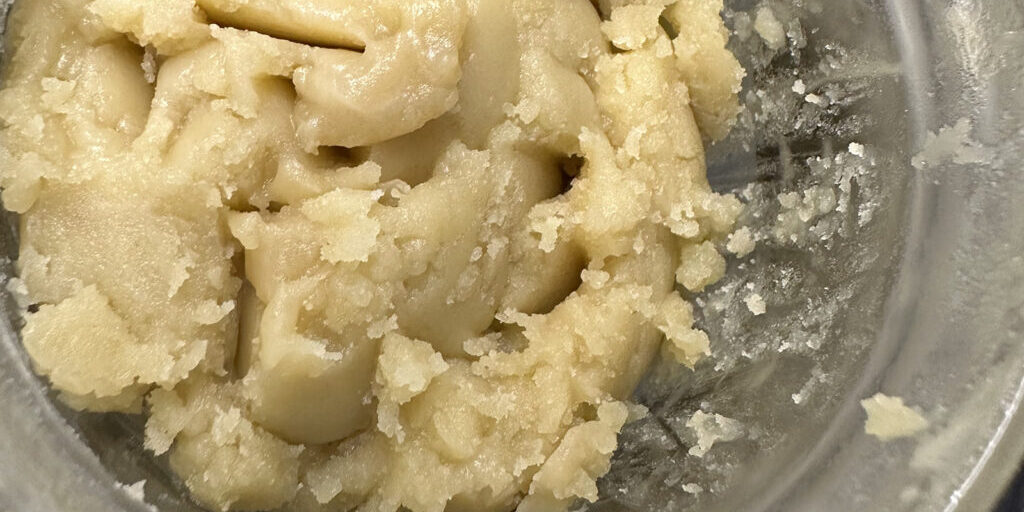

- A more desirable consistency: After a few days of cold curing, your rosin will take on a “badder” consistency, similar to cake batter or butter. Rosin badder is one of the most desirable options on the market, increasing your potential for profits.

- Terpene preservation: While the right extraction method is crucial to preserving the terpenes in your cannabis plant extraction, cold curing can help too. Studies show that above room temperature (around 70 degrees Fahrenheit), volatile terpenes can begin to degrade. Cold curing can enhance the flavor, potency, and consistency of your rosin concentrates.

- Improved flavor and texture: Curing rosin enhances the smoothness and flavor of the dab. Curing fresh press rosin with a cold curing strategy for even a few days after processing can amplify the smoothness and flavor of your cannabis plant.

- Enhanced potency: Rosin pressing can help cultivators retain terpenes and cannabinoids in their cannabis extracts, which is why rosin is one of the most popular types of cannabis concentrates. Since cold cured rosin retains more terpenes, the potency can be higher.

- Reduced oxidation: Oxidation can damage the cannabinoids in your rosin extract, leading to inconsistency in potency and desired texture. Cold curing and whipping (to reintegrate terpenes that have pooled throughout the rosin) can lead to better stability in your extracts.

Equipment Needed for Cold Curing

Learning how to cold cure rosin doesn’t require a lot of specialist equipment. You’ll still need the right processing equipment, and a rosin press to prepare your cannabis plant for extraction. However, most of the resources you’ll need are relatively straightforward.

The most important equipment and tools include:

- Airtight glass jars: These are the primary containers you’ll use for the cold curing process. Avoid silicone and plastic, as these materials can interact with the natural components within rosin, affecting flavor and purity. Glass is non-reactive and doesn’t leach chemicals into extracts, preserving the rosin’s quality.

- A hygrometer: A hygrometer is a crucial tool for measuring the relative humidity inside of a curing jar. Monitoring humidity levels consistently helps to ensure your rosin doesn’t dry out, leading to a loss of terpenes or potency, or becoming overly moist, which can enable mold growth. Look for a digital hygrometer for more accurate readings.

- Storage space: Whether you cure your rosin in a refrigerator or at room temperature, you’ll need to ensure your jars are stored in a cool, temperature-controlled place, free from excess light and humidity. This will help to improve the stability of your rosin and ensure consistency.

Some companies also use humidity packs as an optional extra, to help control the moisture levels within a curing environment. These packs can be particularly helpful in climates where air humidity frequently fluctuates.

How to Cold Cure Rosin: Step by Step

Learning how to cold cure rosin is relatively straightforward, but it does require a calculated approach. Every step, from producing your rosin, to storing your extract needs to be implemented with care. Here are the key steps you’ll need to take.

1. Harvest and Collect your Rosin

One method of collecting rosin is by creating bubble hash and pressing it. Triminator’s Maker™ is an all-in-one system designed for commercial-scale bubble hash production. The ultra-low temperatures and gentle vortex help easily separate trichomes and preserve terpenes. Once you have collected the loose resin from your ice water extraction, it needs to be dried first and then can be pressed into rosin.

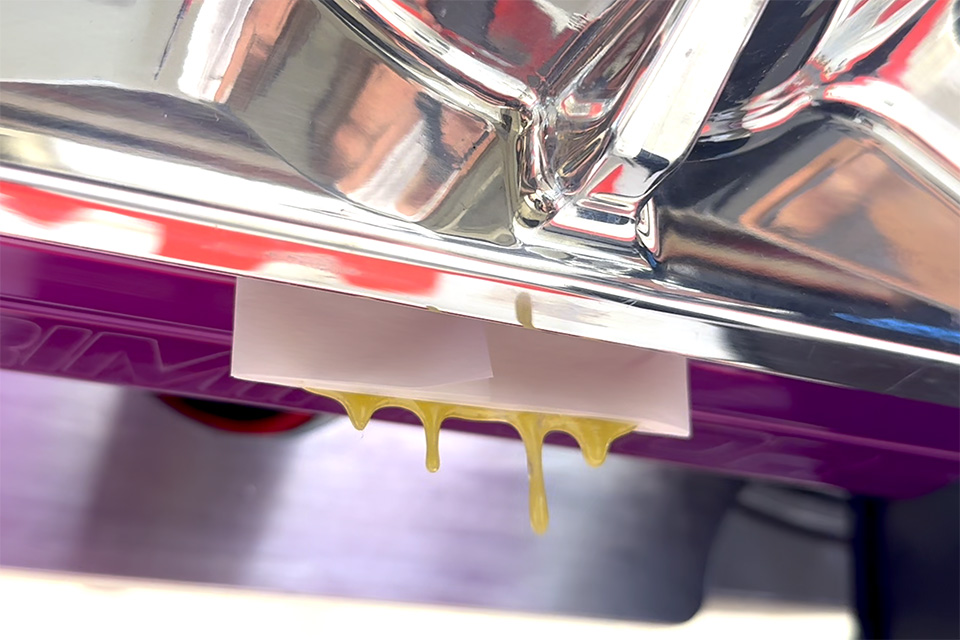

Rosin is created by using a combination of pressure and temperature with either manual or automated machines to press your cannabis plant or loose resin. The Triminator Rosin TRP and Rosin TRP Stack are ideal for creating cold cured rosin, as they are designed for low-temperature, high-yield extraction.

2. Prepare Your Curing Jars

Next, ensure your curing jars are clean and prepared for rosin storage. Glass jars with airtight seals are the best option, as they won’t react chemically with cannabis, helping to retain purity. Ensure your jars are thoroughly cleaned with suitable solutions to reduce the risk of cross-contamination and avoid introducing moisture which will affect your rosin. Proper preparation also helps adhere to safety and industry standards like GMP guidelines.

Open and prepare your jars in a controlled environment to reduce any further risk of contamination before you begin to fill them with your rosin concentrates. It may also be helpful to label jars in advance, to avoid unnecessary handling. Labels should contain information such as batch number, strain type, and harvest dates for proper documentation and product tracking.

3. Fill and Seal your Jars

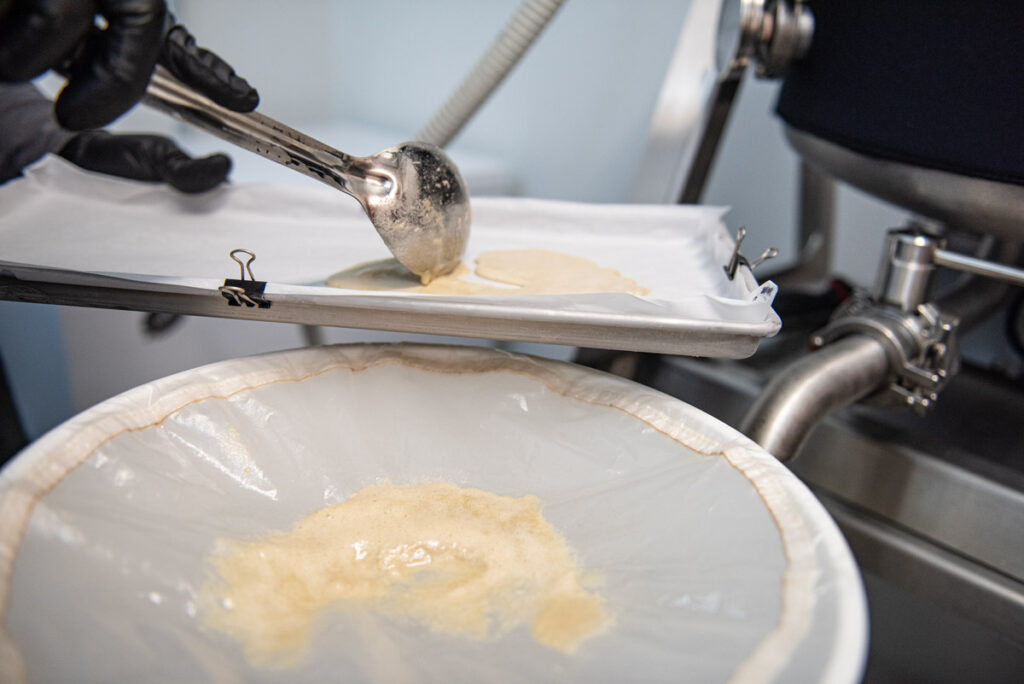

After your jars are prepared and your rosin is pressed, transfer the rosin into your jars carefully. This method of curing is known as Jar Tech. If you have a lot of rosin flowing from your pressing machine during the extraction process, you may use funnels to allow the rosin to run directly into the jar.

Aim to use a jar that closely matches the amount of rosin you will be curing, to ensure there isn’t excess air and lots of space left over. This will reduce the risk of oxidation in your product. Once your jars are filled, seal them carefully, and ensure the seals are airtight.

4. Place the Jars in a Cool, Dark Environment

Next, place your jars in a cool environment to cure. A refrigerator or wine cooler could be an option, but some companies will prefer to choose a cool, dark space where temperatures don’t rise above 70 degrees. Remember, ideal temperatures for cold cured rosin are between 40 and 70 degrees Fahrenheit. Avoid any environments that are subject to drastic temperature changes, due to exposure to outside light or regular foot traffic.

5. Cure for 1-2 weeks, Monitoring Humidity Levels

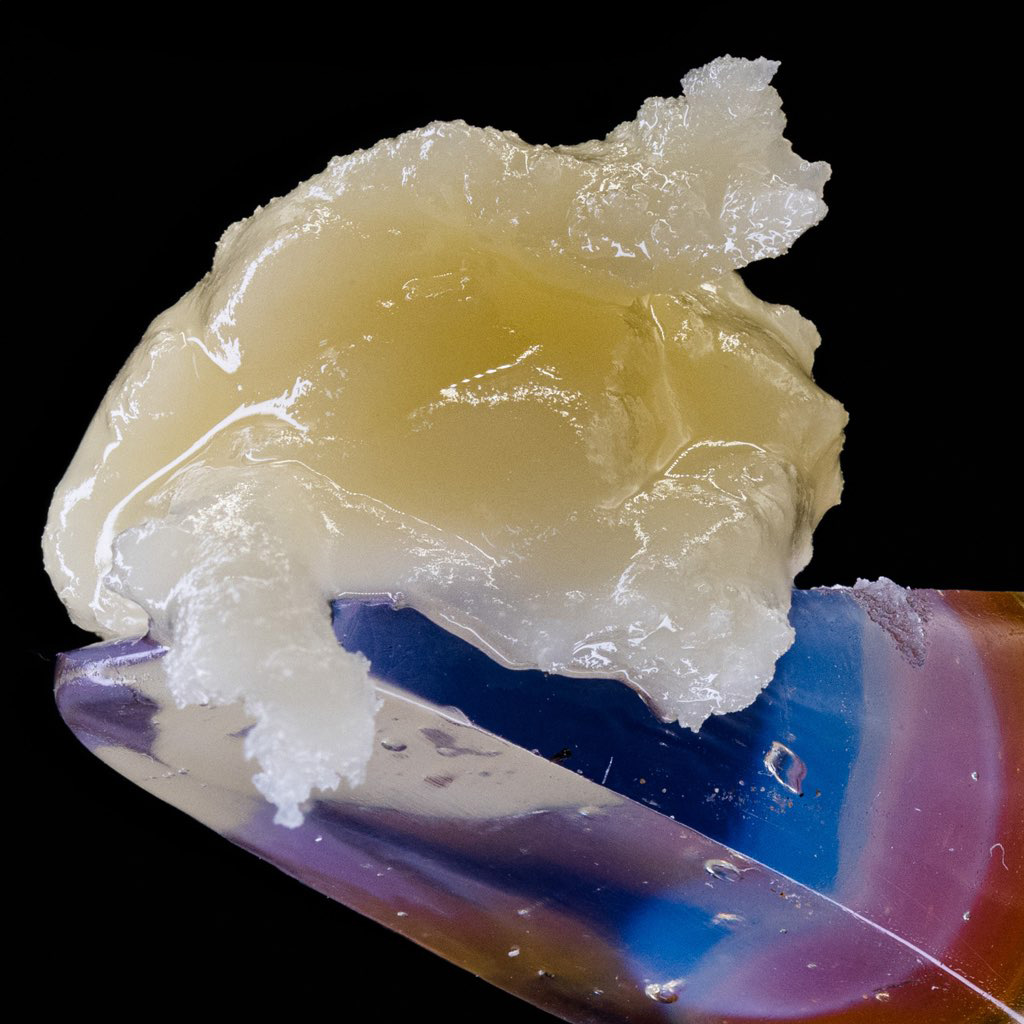

The next step is leaving your rosin to cure. The duration of the cure time will depend on your personal preference, and the specific characteristics you want to achieve for your rosin, as well as the cultivar you’re using. Generally, a curing period of 1-2 weeks should be sufficient to develop the rosin’s flavor, aroma, and texture. The rosin can be kept at room temperature or first placed in the fridge for several days to speed up the process. Be sure to check it regularly for the nucleation process. Nucleation refers to the separation of terpenes and formation of crystals within the rosin. It does not affect purity or potency and is a matter of preference for “sugared-up” rosin or not.

Some cultivators believe a longer cure leads to a better quality final product, however, it will take some experimentation before you find the right strategy for your needs. Throughout the curing process, keep a close eye on humidity levels with your hygrometer, and consider using humidity packs to help maintain optimal humidity levels.

6. Check the Texture and Consistency

After the initial curing period, check the texture and consistency of your rosin. Properly cured rosin should be neither too dry nor sticky and should have a “badder” texture, similar to butter. If terpenes separate from your rosin during the curing process, you may decide to whip or agitate the rosin to help improve stability and consistency.

Depending on your method and results, you may decide to extend the curing time to ensure your rosin reaches your desired consistency. A thicker consistency is ideal for dabbing rosin.

7. Store the Rosin Properly

Once you have achieved the desired results with your rosin, store the rosin properly to maintain its quality. Keep the rosin concentrates in airtight containers, and place them in a cool, dark space. You may also consider placing containers in a refrigerator for long-term storage, to keep the product fresh.

Before selling the rosin, always remember to bring the jar back to room temperature, to ensure the best possible texture and flavor.

Tips and Best Practices for Cold Curing

Cold curing rosin can be an excellent way to enhance the quality of your product in terms of potency, flavor, and texture. Here are some quick tips that can help you master the curing process:

- Start with high-quality material: The quality of your final product is directly related to the quality of the cannabis plant and extract you start with. Choose a plant that’s rich in trichomes and decide on your extraction method ahead of time. Consider the extract carefully when choosing your curing method too; cold curing works best for fresh flower rosin.

- Monitor humidity levels carefully: Pay close attention to humidity levels during the cold curing process. For the best results, use a reliable hygrometer to maintain a humidity range of about 55-62%. Use humidity packs when necessary.

- Be patient: Allow sufficient time for the curing process. Rushing the process can increase your chances of creating a sub-par product. Depending on your methodology and plants, the curing process can take anywhere between a few days to several weeks. Allow the rosin to cure until it reaches its peak quality, based on the strain and strategy.

- Experiment with curing times: Consider experimenting with different curing times to explore the impact they have on your desired consistency, potency, and texture. This is particularly valuable if you’re curing rosin extracted from different cultivars.

- Whip your rosin: Whipping rosin during the curing process can enhance its consistency and stability. Periodically stirring the product introduces air into it, which changes the texture from sticky and sap-like to something smoother and more buttery. Whipping can also help distribute heat, and reintegrate terpenes back into the mixture.

- Use a straight jar during curing: When you use a straight-sided jar—rather than one that is tapered or has a narrow opening—collecting the rosin is much easier, especially with maneuvering a dab tool through the opening and scraping the sides.

Discover the Benefits of Cold Curing

Cold curing rosin can provide many new opportunities for your cannabis extracts. The cold curing process offers an excellent way to create a highly desirable finished product, with an appealing badder texture, and carefully controlled levels of consistency and potency.

The key to success is having the right equipment, and strategy in place to make the best possible final product. At Triminator, we offer cultivators a range of innovative tools they can use to enhance the cold curing process, from automated rosin presses to hash washing equipment. Contact Triminator today to discuss your cold curing needs with us, and discover the perfect resources for optimizing your rosin extraction strategy.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields