How to Thrive as a Cannabis Grower in a New Market

The 4 Essentials for Success as a New Cannabis Cultivator

Congratulations! You’ve won a license to cultivate cannabis in a new market. But it’s not all fun and games — now the real work starts.

Whether you’re licensed in New Jersey, Arizona, or any of the other states that legalized cannabis in 2020, there are some unexpected hurdles you’ll need to clear to succeed.

At Triminator, we’ve seen a lot of grow operations. And because we provide harvest-time solutions, we have some perspective into the business and cultivation practices that create the best outcomes.

In this post, we share some perspective on how to execute a successful harvest and which tactics will be most helpful to your startup. So, without further ado, here are the four essentials that you’ll need to succeed as a new cultivator in an upstart market:

#1 Know Your End Product and Find Your Facility

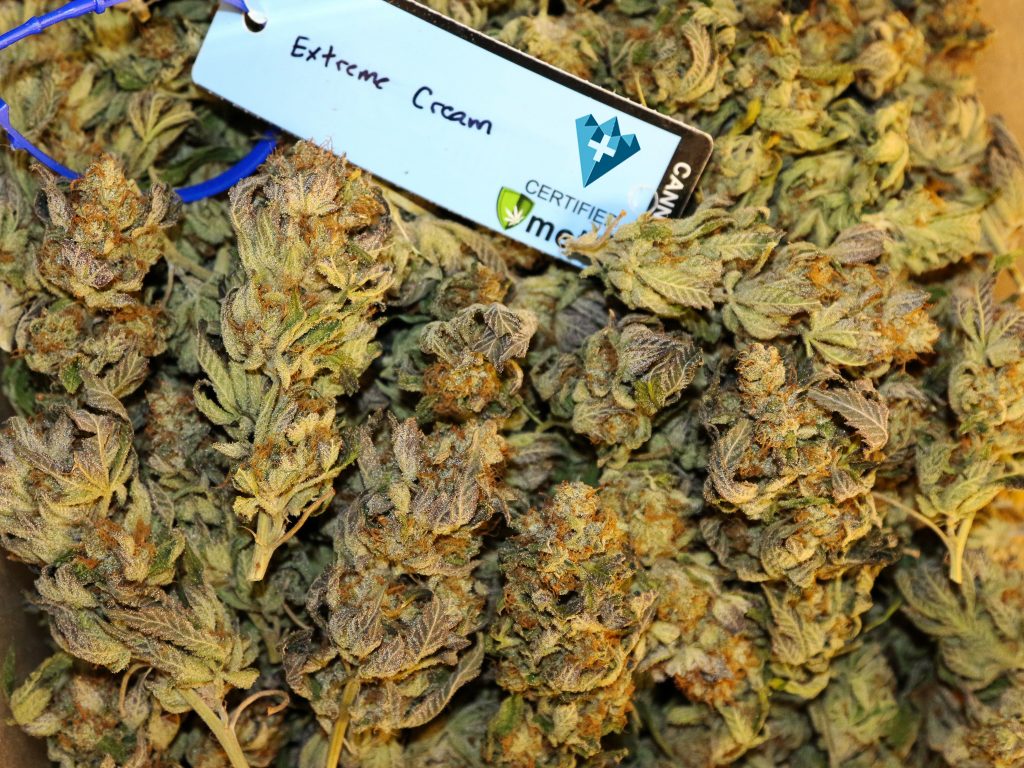

Not all cannabis is created equal, and not all grow ops will yield the same cannabis. Many aspects of your cultivation plan — location, genetics, equipment, etc. — will hinge on your desired end product.

Do you want to grow boutique cannabis? Or would it make more sense to focus on volume and extraction-grade crops? Assess your local market before deciding. You’ll likely find that mid-grade cannabis grown in high volumes trumps a single-minded focus on quality. You may also find a niche with heirloom varieties or genetics that focus on minor cannabinoids.

With your desired end product in mind, you can seek out suitable real estate. Outdoor growing is the least expensive, but it typically yields a lower-quality product and leaves you exposed to the elements — literally. Weather events and forest fires can devastate your returns.

Greenhouses provide more control over the grow op, and you’ll get higher-quality flower with a lower chance of crop failure. And because greenhouses utilize natural light (usually in addition to supplemental lighting), you’ll have lower operating costs than indoor facilities.

But expect much higher capital expenditures with a greenhouse. Building a greenhouse from the ground up is the most expensive way to get started, and it proves cost-prohibitive for many new companies. Retrofitting an existing greenhouse is expensive too because artificial lighting, light deprivation systems, and HVAC drive up the costs.

Indoor growing gives you the ultimate control over your plants. If you want top-shelf flower, indoor cultivation will likely be your choice. Total environmental control means that you can “play God” with every cultivation metric, from light levels to humidity. The trade-off for increased control is the highest operating costs of any cannabis grow. Without sunlight, your electric bills will be significantly higher.

#2 Build a Cannabis Compliance Plan

After you win a license, sit down and read your regulations. All of them. It’s not the most enjoyable part of owning a cannabis business, but maintaining regulatory compliance is critical for success.

Instead of avoiding the local authorities, befriend them. Ask your regulators specific questions if you’re in doubt about the rules, and always welcome their presence at your facilities. Ultimately, you and the regulators share the same goal: a safe cannabis industry that thrives for years to come.

You’ll probably want to appoint a compliance officer — someone with a background in cannabis or another regulation-heavy industry such as healthcare. They can help you develop formal standard operating procedures (SOPs). SOPs not only keep you compliant; they can assist with employee training and implementing policy changes. Third-party consultants may be helpful if you’re struggling to build out good SOPs.

Your compliance plan and SOPs should include descriptions of your:

- Transportation logistics

- Documentation protocols

- Track-and-trace interfacing

- Security hardware and procedures

- Facility diagrams, cultivation procedures, and plant counts

Once you get your plan complete, be prepared to change it. Regulations shift, especially in new markets. To stay compliant, you’ll need to do a lot of heavy reading. Reflecting on the best practices in uber-regulated markets like California can help your compliance plan go above and beyond. That can make you ready for more stringent standards, should they be implemented.

#3 Nail Down Your Cultivation Plan

Your head grower should have experience in commercial cultivation. Cannabis-cultivation experience isn’t strictly necessary; growers who have supervised ornamental production or vine crops are very capable, especially if they hold a degree in agronomy.

How you build out your facility will have a big effect on your long-term success. The equipment choices you make now — HVAC, lighting, fertigation — will not only dictate your operating expenses, they’ll affect your ability to grow quality product.

Make sure you have these things in place before starting your first crop cycle:

- A detail-oriented head grower with experience in commercial growing

- A compliant facility designed for your goals and long-term success

- Well-trained cultivation technicians

- SOPs for all cultivation tasks

- Plans for processing and selling the crop

Hire a consultant for your facility design or retrofitting. Even capable head growers will struggle to pair equipment systems for optimal results. In reality, determining a facility’s HVAC needs is a complicated math-intensive dive into the physical sciences. Greenhouses are especially tricky to outfit because they’re subject to changing light conditions and massive heat gain from the sun.

The most oft-neglected areas of cultivation plans are pest management and fertigation. The water quality at your facility will have a dramatic effect on your results, and it may come as a surprise that the quality of your tap water shifts frequently. You’ll want to monitor the pH of your tap water, and, if you’re mixing nutrients, analyze its chemical content before you start mixing.

Integrated pest management (IPM) is how your facility will keep pests and pathogens at bay over the long term. Many jurisdictions have pesticide restrictions (and many pesticides don’t work). So, you’ll want to employ alternative methods such as biological controls and, of course, frequent scouting of your crops to head off problems before they start. Pest-related crop failure can devastate fledgling companies, and proactive pest management is easier than correcting problems.

#4 Have a Processing Plan Before You Start

Many growers harvest their first crop only to find that they’ve underestimated the space or resources it takes to trim, dry, cure, and package the product. Trimming cannabis flower is a labor-intensive endeavor — one that can push your payroll past the limit.

The delays and expenses of cannabis processing impact new companies at the worst possible time: before revenue starts. The burn rate of a new cannabis grow operation often exceeds expectations. That’s why it’s important to plan how you’ll process your crop before you plant it.

You’ll want to size your drying rooms in proportion to your cultivation area. And make sure that the drying rooms are equipped with an HVAC system that can maintain temperatures in the range of 65-70 ℉ and humidity levels of 50-60%.

Another pivotal processing question is when you’ll trim. Some growers prefer to trim their buds after they have dried; others like to trim while the plant material is still wet. There’s no right or wrong way to trim, but you’ll want to decide early on whether dry trimming or wet trimming is right for you.

Dry trimming typically provides a higher quality product because the whole plant dries slowly and naturally. But it can create some logistical challenges. You’ll need to dry the plants whole, and string them upside down, which takes more space than the wet trimming protocol. You’ll also need to time your trimming day just right so your bud has the ideal moisture content for the trimmer. If you choose a dry trimmer, we can help you know when you’re ready to trim.

Wet trimming is simpler and quicker. You buck your buds (that means you seperate the flowers from the stalks), and you feed them into the trimmer. After they’re trimmed, they can dry in vertical racks, which greatly reduces the space you’ll need for dry. However, separating the buds also speeds up the drying process, leading to the loss of sensitive cannabinoids and terpenes.

At Triminator, we help cultivators choose trimming solutions that work for them. Not everyone is the same, and your cultivation goals are unique. So we consider more than just your budget and production volume when helping design your processing plan.

Whether you’re a large-scale outdoor grower or starting off with a shipping-container grow room, we have trimming equipment to streamline your processing without compromising product quality. Sign up for our email newsletter for more information on how to process cannabis — and how to succeed as a grower in new markets. Or, if you’re ready to get started, contact a Triminator representative today.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields