Machines and orders over $3,500 ship FREE*

*Restrictions apply. See Shipping Information for details.

You might also LIke...

-

Nylon Rosin Press Bags

$20.00 Add to Cart This product has multiple variants. The options may be chosen on the product page -

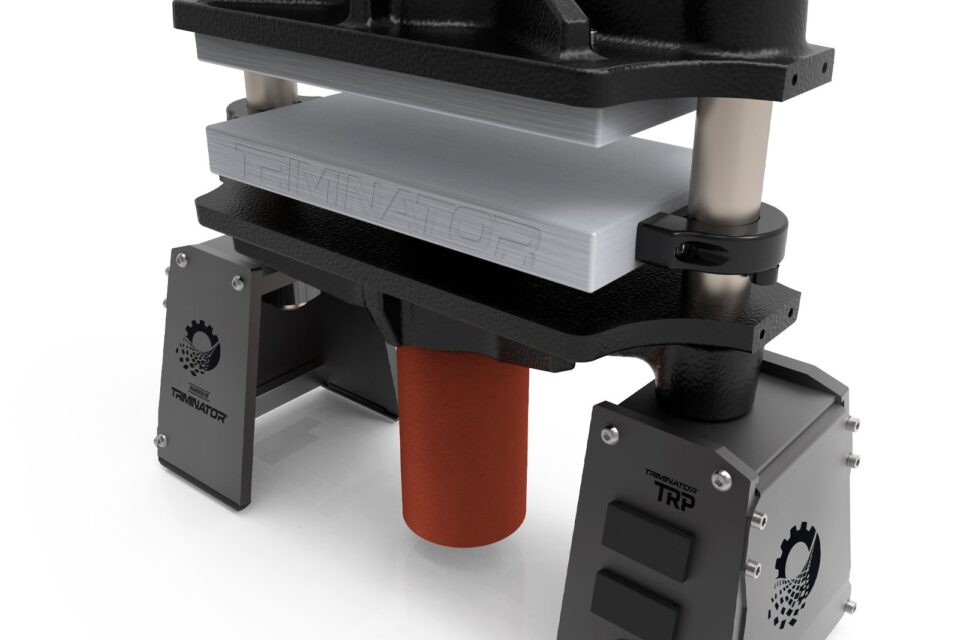

TRP Rosin Press

$3,325.00 Add to Cart -

Sale!

TRP Stack Rosin Press

Original price was: $5,980.00.$4,600.00Current price is: $4,600.00. Add to Cart -

Manual Hand Pump

$625.00 Add to Cart