The Ultimate Guide to Pressing: Rosin Press Temp Chart

If you’re looking for a way to scale your business and increase profits, pressing rosin could be an excellent solution. Rosin will allow you to tap into the rising demand for cannabis concentrate products, expected to be worth $18.5 billion by 2030.

However, your success in this market depends on your ability to find and use the right temperature settings with your rosin press equipment. Heat plays a crucial role in influencing product outcomes. Even if you want to cold press rosin, a temperature too low can negatively impact yield, potency, and flavor.

If you’re using warm or hot pressing strategies, a temperature too high can harm rosin consistency and degrade cannabinoids and terpenes. Here’s your ultimate guide to getting temperature settings just right and preserving your brand’s reputation.

Understanding Rosin Press Temperatures

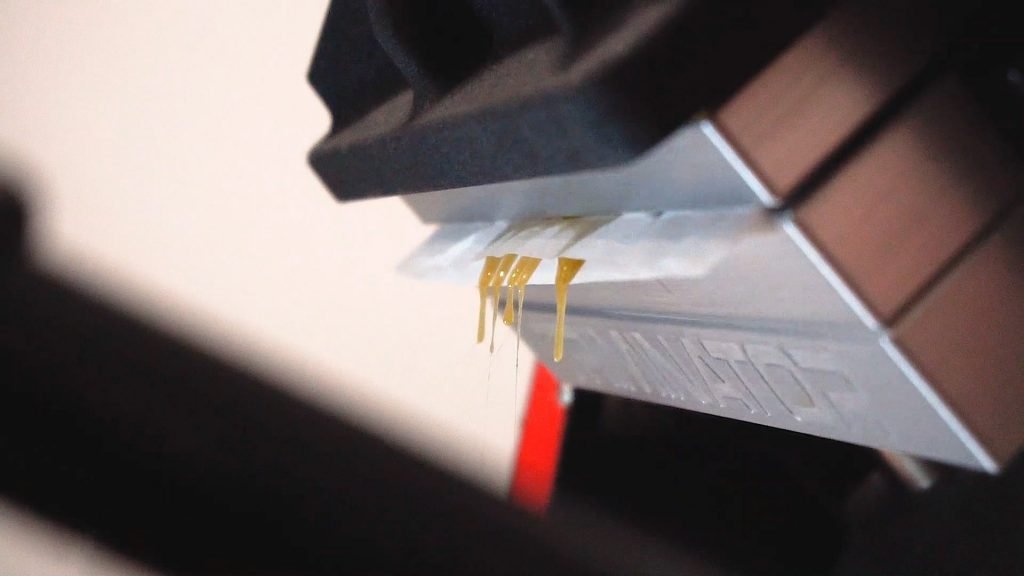

Rosin pressing is a popular method cultivators use to extract cannabinoids and terpenes from flowers without the use of solvents. The process relies heavily on the careful application of heat and pressure to cannabis, using state-of-the-art extraction equipment.

In recent years, the popularity of rosin pressing has increased thanks to the growing demand for cannabis concentrates and solventless extraction options in the market. Unlike other extraction methods, rosin pressing ensures no residual chemicals are retained in your final product.

The Role of Temperature in Rosin Extraction

The temperature of the plates in your rosin press has a direct impact on the product’s quality, as well as your ability to derive substantial profits from the products you sell. Careful temperature control (combined with pressure control) affects a number of factors, including:

- Consistency or Viscosity: At lower temperatures, extracted rosin tends to be more stable, less runny, and more potent. However, pressing at lower temperatures can result in lower yields, as the rosin does not flow as freely from the plant material.

- Color and Clarity: A soft, translucent color and high levels of clarity demonstrate a high-quality extraction, but it’s often difficult to achieve. Higher temperatures are more likely to produce a darker rosin, while lower ones deliver lighter colors.

- Terpenes and Effects: There is data that suggests terpenes are more likely to degrade at warmer temperatures. This is one of the reasons cultivators experiment with cold pressing, creating ice water hash, and using fresh frozen cannabis to make live rosin.

- Flavor: Higher temperatures can also have an impact on the aromatic and flavor compounds that affect the overall taste of a rosin product. Since higher temperatures can contribute to greater terpene loss, flavor can suffer.

- Yield: However, higher temperatures do positively impact yield. Using greater heat when pressing kief, flower, or hash rosin will increase fluidity, which can be beneficial when you’re working with less resinous material. It’s important to carefully balance the temperature to increase yield without causing excessive terpene loss.

Temperature Ranges for Rosin Pressing

Ultimately, the best temperature for your rosin press will depend on your specific goals, the products you’re using, and various other factors. Let’s break your options down into two clear segments: lower and higher temperatures.

Cold Press / Lower Temperatures (130°F – 170°F)

Cold pressing, or pressing rosin at colder temperatures, such as between 130°F and 170°F is ideal for preserving the delicate terpenes and cannabinoids that contribute to the aromatic and flavor profile of your concentrate. This range is often preferred by solventless extract cultivators seeking high-quality rosin with great clarity and superior taste. Operators will often sacrifice yield to achieve a “buddery” texture.

Lower temperatures maintain the integrity of essential compounds but can yield lower volumes of rosin due to the resin being less fluid and harder to extract.

Hot Press / Higher Temperatures (170°F – 220°F)

Mid-range temperatures between 170°F and 220°F offer a balanced approach to preserving quality, and enhancing yield, which could be ideal for scaling companies. This range is popular among many cultivators because it allows for good extraction efficiency while still maintaining a significant portion of the terpenes and cannabinoids.

The rosin produced at medium temperatures often exhibits a satisfying blend of potency and flavor, although it might have a slightly darker color compared to lower-temperature presses.

Factors When Selecting Rosin Press Temperature

Numerous factors, from the starting material you use to your available equipment, can affect your ideal rosin press temperature.

Strain Varieties

The type of cultivar you use plays a significant role in determining the right temperature range. Different strains all have unique profiles of cannabinoids and terpenes that can respond differently to heat. For instance:

- Indica strains: Indica strains can usually have a higher resin concentration, which means they can still offer excellent yield at lower temperatures

- Sativa strains: Compared to Indicas, Sativa strains typically have a more delicate terpene profile and less resin. To preserve these terpenes, cold press at lower temperatures. However, less resinous plants may produce a lower yield at these low temperatures.

- Hybrid strains: Hybrid strains typically require a balanced approach.

Moisture Content and Relative Humidity

High moisture content in a plant can lower the effective temperature range required for pressing. High moisture can sometimes assist in creating steam, which helps with rosin extraction. Products with lower moisture content can require higher pressing temperatures (or greater pressure), to ensure the rosin can flow freely. However, careful monitoring is crucial to avoid burning the material and losing valuable terpenes and cannabinoids.

The optimal moisture content and relative humidity levels of your starting material will depend on what type of material you are pressing. The levels for fresh flower (for pressing live rosin) will vary from the levels for dried and cured flower, as well as for pressing kief and hash. For example, when pressing dried flower for rosin, the moisture content should be around 10-15%. Your starting material should also contain a relative humidity range between about 58-65%. This range allows for optimal resin flow and terpene preservation.

To obtain your moisture content levels and relative humidity range, you can perform some simple, inexpensive tests. Moisture content can be determined using a moisture meter, which measures the amount of water within the flower. Relative humidity can be found by placing your material in an air-tight container with a digital hygrometer and monitoring for about an hour, allowing the levels to stabilize. This shows you how wet the material is, relative to the atmosphere, which greatly affects your yields.

The Type and Volume of Material

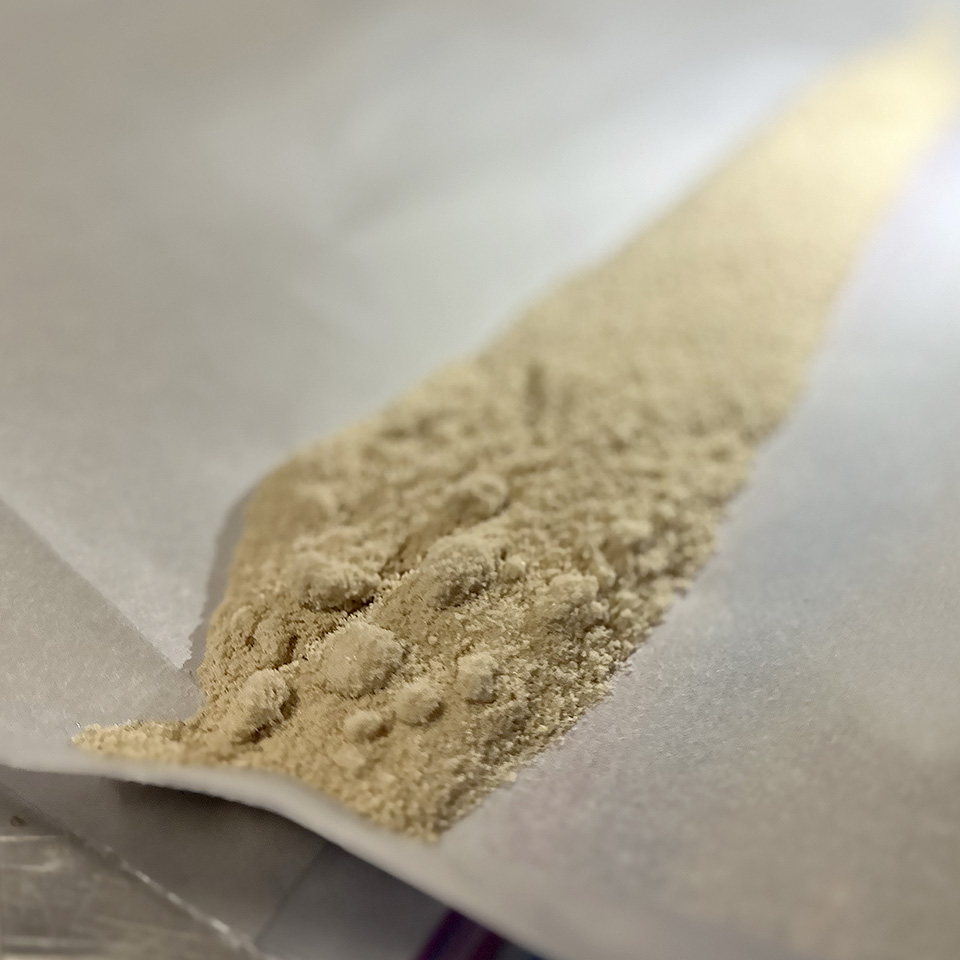

The type of material being pressed, whether it’s flower, kief, or hash, also affects the temperature requirements.

Flower: Pressing flower requires a careful temperature and pressure balance to avoid burning the material or harming terpenes while ensuring good resin flow.

Kief: Kief is more resinous and less fibrous than flower, so it can usually be pressed at lower temperatures. This helps preserve the terpene profile while ensuring a high yield.

Hash: Hash is even more concentrated than kief. Pressing hash at slightly higher temperatures can help melt the resin effectively. However, care must be taken to avoid over-pressing, which can lead to a darker, or less flavorful resin.

The volume of material you are pressing at a time also plays a role. Lower temperatures can be better suited to smaller batches, as they will heat up quickly and evenly, reducing the risk of burning. Large batches of five grams and above may require higher temperatures and a greater focus on even heat distribution.

Depending on the volume of material, using the right accessories, such as a pre-press mold and carefully chosen rosin pressing bags, will also help ensure even heat distribution.

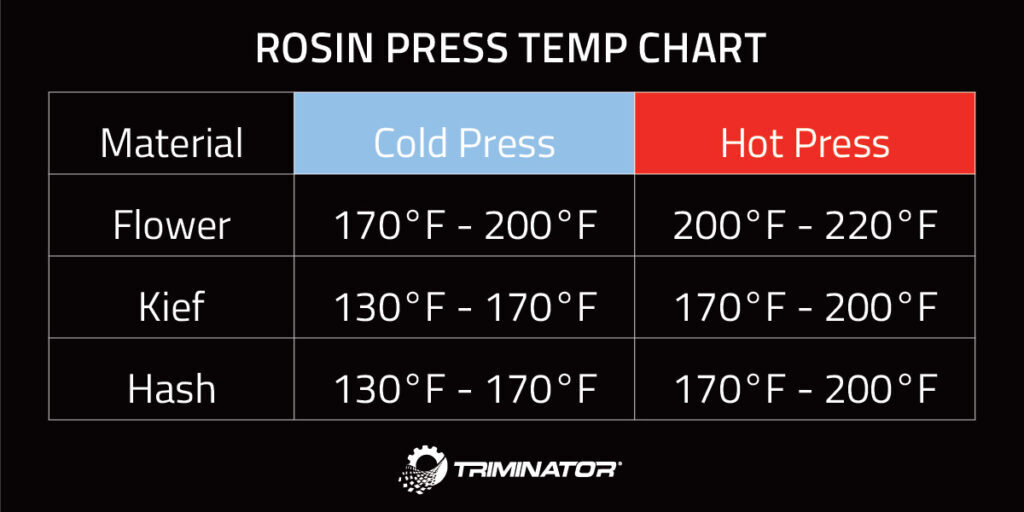

Rosin Press Temperature Chart

| Material | Cold Press | Hot Press |

| Flower | 170°F – 200°F | 200°F – 220°F |

| Kief | 130°F – 170°F | 170°F – 200°F |

| Hash | 130°F – 170°F | 170°F – 200°F |

Key Takeaways:

Fresh Flower: Fresh flowers contain more moisture, which aids in resin flow at lower temperatures and preserves more terpenes, though the yields are typically smaller than with dried and cured flower.

Dried Flower: Maintain your flower at around 10-15% moisture content to avoid having to rehydrate your material, and keep the relative humidity between 58-65%. Monitor the flower throughout the drying and curing steps to prevent excessive dehydration and utilize a relative humidity test to obtain better yields. With flower being more fibrous, higher temperatures are required to create a quality product and maximize yield.

Kief and Hash: Being more resinous and potent, kief and hash are best pressed at lower temperatures to maintain terpenes and achieve high yields. Ensure your material is properly collected and dried prior to pressing to achieve the best consistency.

Tips to Find the Best Temperature

Finding the best rosin press temp for your extraction process can require some experimentation. You may need to adjust your temperature strategy regularly, to explore the effect different levels of heat and pressure have on various cultivars and products.

Some quick tips to keep in mind include:

- Start with low temperatures and gradually increase: Generally, it’s best to start at the lower end of the recommended temperature range and increase gradually to boost yield.

- Monitor temperature accuracy: If your pressing equipment does not have one built in, use a reliable temperature gauge, and calibrate your equipment regularly for consistent temperature readings.

- Perform a relative humidity test: Understand the moisture content and relative humidity of your starting material before pressing. Knowing what range your material is in will help inform your processing for better extraction efficiency.

- Experiment with small batches: Conduct smaller initial presses with new cultivar batches to determine how temperatures influence yield and quality.

- Pay attention to results: Pay attention to the consistency, terpene profile, and appearance of the rosin as it is extracted, and keep a log of your observations.

- Remember the pressure balance: When pressing rosin, ensure you have the right balance between temperature and pressure.

Adjustments Based on Desired Outcomes

Remember, the best temp for hash rosin will be different from the best temp to press flower or the temperatures you use when pressing kief. However, there are some basic best practices you can follow to achieve specific goals:

- For greater yield: Gradually increase temperature and pressure within the recommended range to increase output, particularly for less resinous material.

- For better potency and flavor: Stick to lower temperatures to preserve delicate terpenes and cannabinoids and avoid flavor issues.

- Balancing yield and quantity: Use mid-range temperatures for a balanced approach, adjusting your strategy based on your cultivar’s characteristics.

Remember to consider other factors too, such as ambient temperatures and humidity levels in your processing room, which can affect how rosin flows during the extraction.

The Ideal Temperature for Rosin Pressing

Ultimately, there’s no one-size-fits-all strategy for choosing the right rosin pressing temperature. Just as your ideal processing equipment and strategy will vary based on various factors, the right temperature will depend on a range of considerations.

Choosing temperature carefully will ensure you can directly influence the quality, yield, and characteristics of your final product. Make sure you select equipment that allows you to adjust temperatures based on strain type, moisture content, and material, keep our rosin press temp chart handy, and constantly experiment to discover what delivers the best results for you.

For help choosing the right equipment for your rosin pressing strategy or more insights into optimizing your extracts contact the Triminator team today.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields