Machines and orders over $3,500 ship FREE*

*Restrictions apply. See Shipping Information for details.

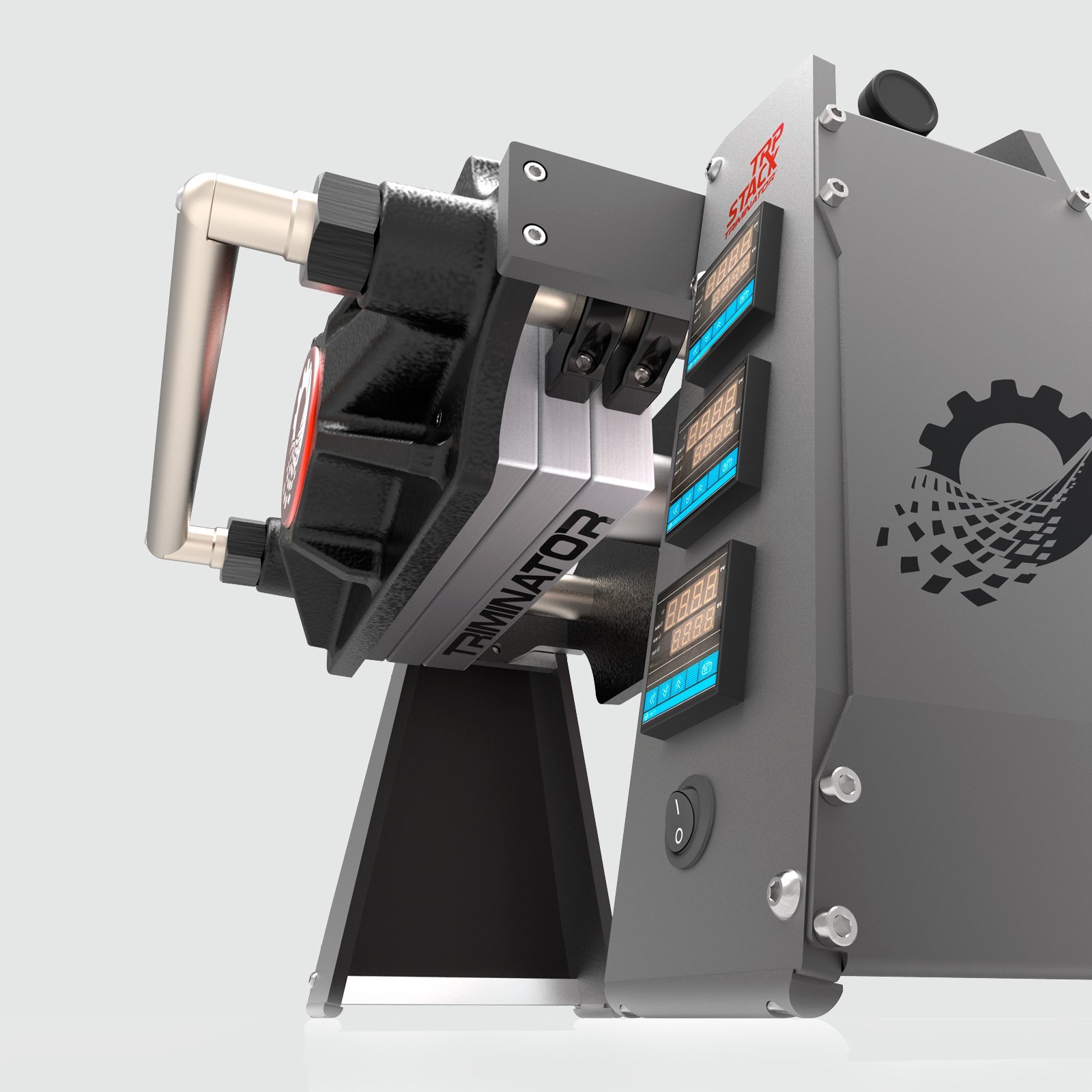

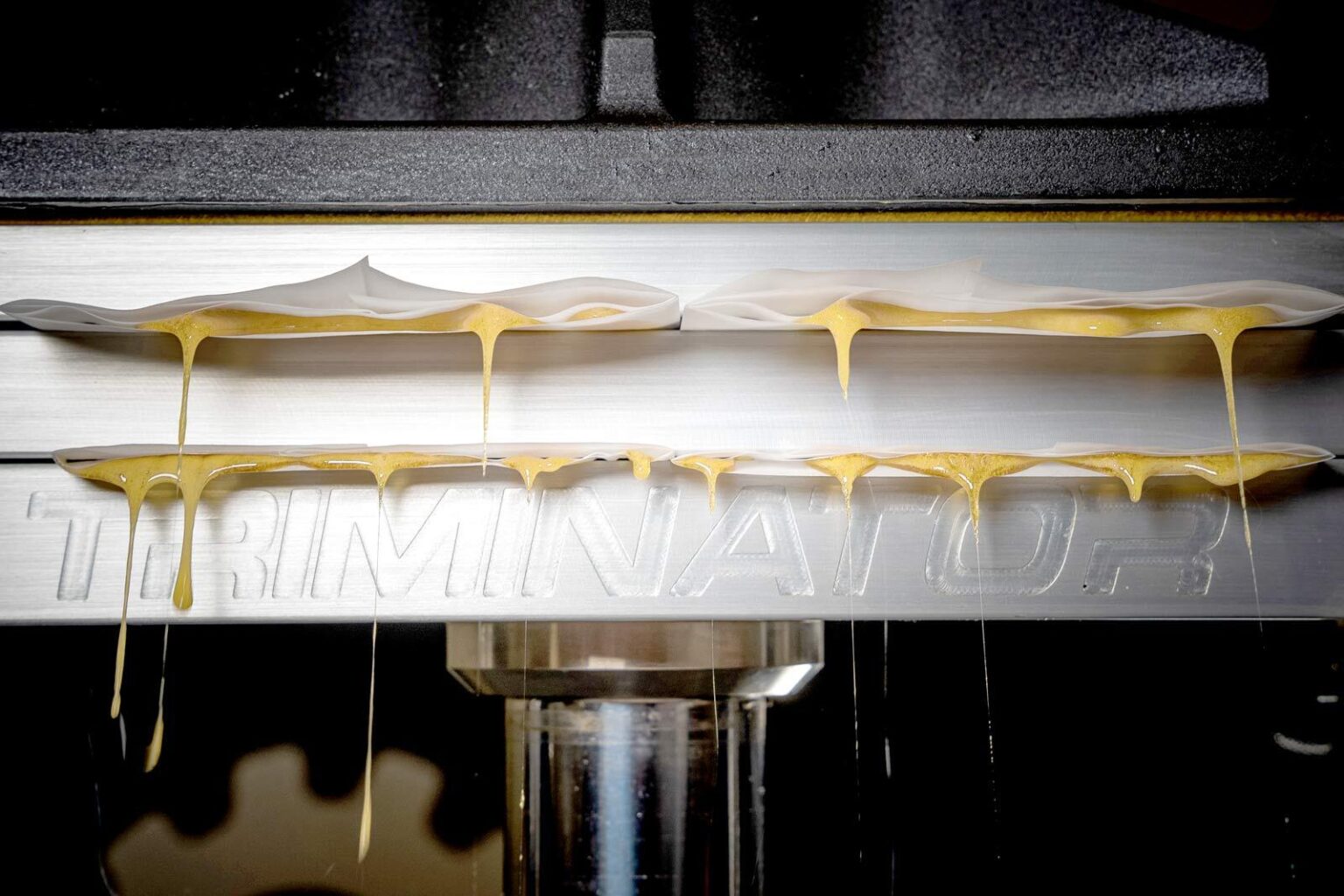

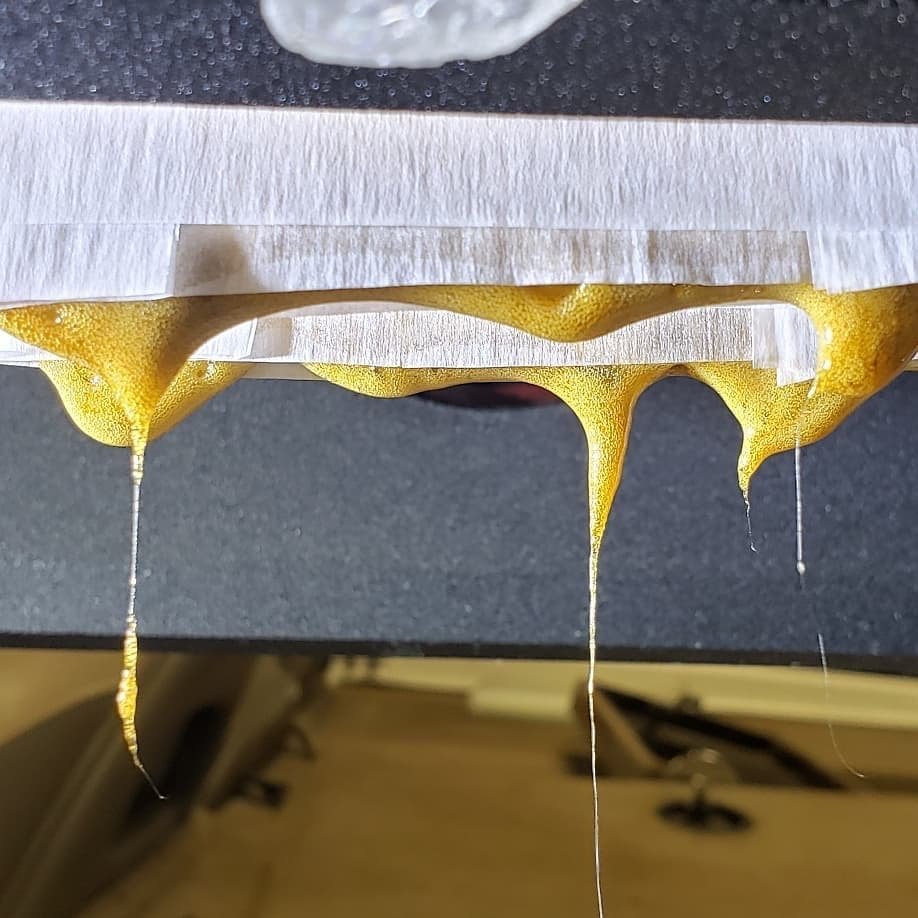

Produce outstanding solventless rosin at scale with the Triminator TRP Stack Commercial Rosin Press. Preserve terpenes while pressing award-winning bubble hash, sift, and flower rosin. The revolutionary Rosin TRP Stack features multiple food-grade aluminum platens for faster production and patented Easy Pivot™ drip technology for terpene-rich, high-quality rosin.

In the competitive cannabis retail environment, the TRP Stack solventless Rosin Press allows growers to maximize their profit and create additional revenue by adding one of the most valuable SKUs to their retail offerings. Triminator’s innovative rosin press technology makes it easy for you to turn your product into market-leading rosin and cannabis concentrate.

TRP Stack

Commercial Rosin Press

Benefits

Used by Best Solventless Emerald Cup Award Winner

Industry-Leading

Technology

Specifications

Height

22 IN / 57 CM

—

Width

27 IN / 69 CM

—

Length

13 IN / 33 CM

—

Weight

151 LBS / 68 KG

—

Power Req

120 V, 20 P

—

Drip Tech

Yes

—

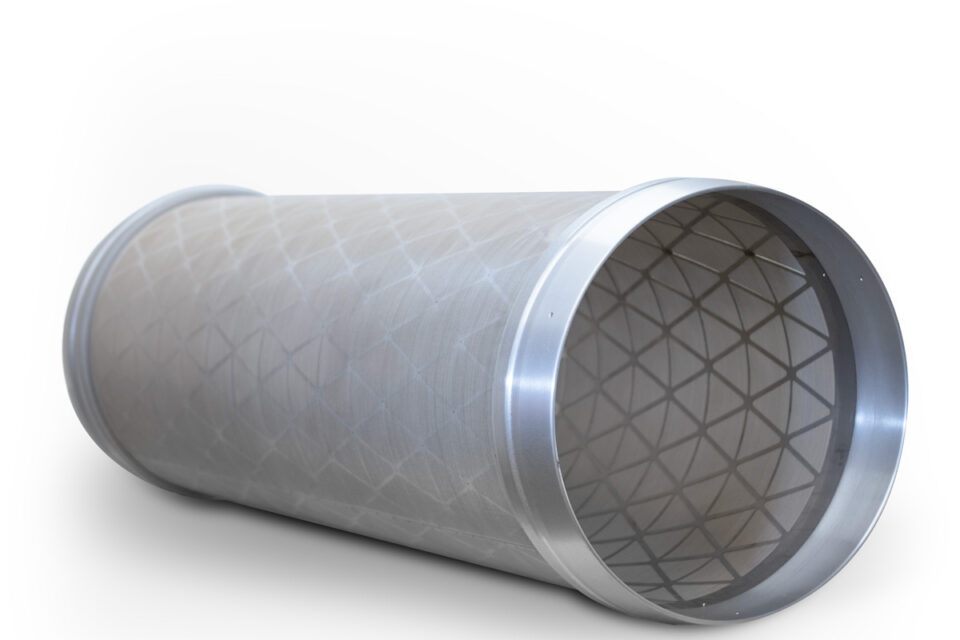

Platen Size

6 IN X 10 IN / 15 CM X 25 CM

—

Platen Count

3

PDF Downloads

Learn from our rosin education team

Set the Temperature

Individually adjust each platen’s temperature in a few easy clicks. Wait 15 minutes for the temperature to stabilize.

Note: This video features the original Triminator TRP Rosin Press with controls similar to the triple-platen TRP Stack.

Attach Your Pump

Attaching your hydraulic line is simple. Insert your hose and thread the connector together until they’re finger-tight. No tools are needed!

Fill Your Bags

Fill your rosin bags loosely to avoid breakage. Remember to position parchment paper below the TRP Stack when using the Easy Pivot drip tech system for terpene retention.

Frequently Asked Questions

It depends on your input material - and your rosin press. For high potency materials like bubble hash, aim low. A temperature of 170-180°F will work well.

For flower and trim, you’ll need more heat or pressure to flow the oil out of the biomass. Think 190-210°F, but no more than 220°F.

Note: These temperature stats may be significantly higher if you’re not using the TRP Stack when lower pressures are used.

Ready to press some rosin?

You might also LIke...

-

Air Hydraulic Foot Pump

$750.00 Add to Cart -

Dry Trimmer

$3,375.00 Add to Cart -

Manual Hand Pump

$625.00 Add to Cart -

Triminator Kief Kit

$725.00 – $2,225.00 Add to Cart This product has multiple variants. The options may be chosen on the product page

Robert –

Really awesome machine. The duel stack capability really allows this machine to commercially produce. There is nothing around the machine to hide from cleaning. The 90degree tilt feature makes this machine. I do wish it had a lock on the tilt feature, enabling easier transport. Expensive, but really makes the workhorse package complete.

Overall, this is the best machine on the market, right now.

Tyler P –

Given the price of the TRP, I wasn’t sure if I wanted the more expensive model but turned out to be better than I expected. It’s probably the only press that PIVOTS so rosin drips down instead of you scraping to collect. That saves time if you’re running a business and much needed! Got about 20% yield from flower using the bonus bags it came with!

PROS: Excellent press! Great build quality. Made in USA

CONS: It’s heavy so don’t expect portablility