Rosin vs Resin

Maximizing Profits in Your Cannabis Business

Rosin vs resin: Which form of cannabis concentrate should your business be prioritizing? Both rosin and resin are highly potent products gaining attention in the growing cannabis market, set to reach a value of $444.34 billion by 2030. However, while they sound similar, they’re actually very different.

Though resin and rosin are both high in terpenes and cannabinoids and can be consumed in various ways, they require different extraction and processing methods and deliver varying results.

Here, we’ll guide you through the process of understanding the differences between resin and rosin and how you can choose the right product to maximize your profitability.

Understanding Rosin and Resin

Defining Cannabis Rosin

Rosin is a cannabis concentrate created through a solventless extraction process. This makes it a popular product in the solventless market, a category that grew in value by over 132% each month between 2021 and 2022.

Rosin comes in a range of forms, including:

- Live Rosin: Rosin is made from fresh or flash-frozen cannabis plants. Live rosin offers a robust flavor profile and a high potency, thanks to well-preserved cannabinoids and terpenes.

- Dry Sift Rosin: Extracted from dry sift or kief, this form of rosin is often high in quality, with significant potency and flavor.

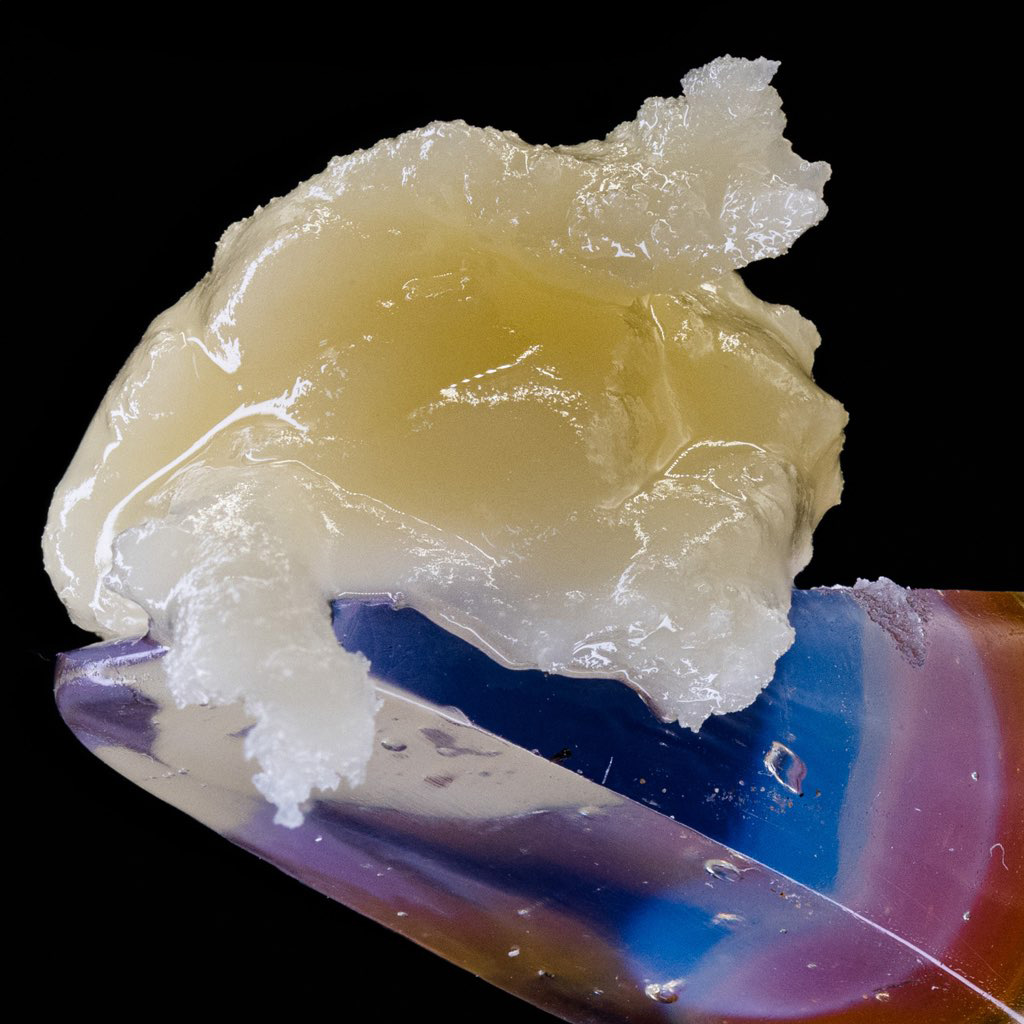

- Hash Rosin: Derived from bubble hash, hash rosin is regarded for its purity and potency, as well as its broad trichome and terpene profile.

Rosin is typically extracted from cannabis plants by using controlled heat and pressure. The pressure and heat cause trichomes to separate from the plant material and flow out, creating the desired product. Rosin is often used for dabbing, vaping, and infusions and is highly prized for its purity due to the use of solventless extraction methods, which eliminate residual solvents.

Many consumers also love rosin for its flavor and potency, which are created by preserving terpenes and cannabinoids, and its artisanal quality.

Defining Cannabis Resin

Resin is a broad term used to describe cannabis concentrates extracted using CO2 or chemical solvent extraction methods. They lack the “purity” appeal of rosin products but still offer exceptional potency. In fact, studies have shown that the resin’s potency has increased by nearly 25% in the last 50 years.

Like rosin, resin can come in various forms, such as:

- Live Resin: Live concentrates are made from fresh or flash-frozen cannabis to preserve a higher concentration of cannabinoids and terpenes. Live resin has a flavorful and aromatic profile.

- BHO (Butane Hash Oil): Extracted using butane as a solvent, BHO is known for its high potency and versatility, available in various consistencies like shatter, wax, and budder.

- CO2 Extracted Resin: This form of resin uses carbon dioxide as a solvent to produce a potent product.

Typically, resin is extracted from cannabis plant matter using solvents. The cannabis material is reduced in the solvent, such as butane or CO2, to dissolve terpenes and cannabinoids, and then the solution is purged to eliminate the residual solvent from the final product.

Like rosin, resin concentrates are popular for dabbing, vaping, edibles, and topicals. It generally has a high cannabinoid content, making it appealing to users in search of strong effects, and it’s available in a range of consistencies and forms to appeal to different consumer preferences.

Quick Comparison:

| Rosin | Resin | |

| Extraction Method | Solventless, using heat and pressure. | Solvent-based, using butane, CO2, or other solvents. |

| Purity | Free from residual solvents, highly pure. | May include small amounts of solvents. |

| Market Appeals | Appeals to health-conscious consumers and connoisseurs seeking artisanal quality. | Attracts users looking for high potency and a variety of product forms. |

| Production Efficiency | Smaller yields, more labor-intensive. | Higher yields, more cost-effective production. |

Differences Between Processing Rosin and Resin

Processing Rosin

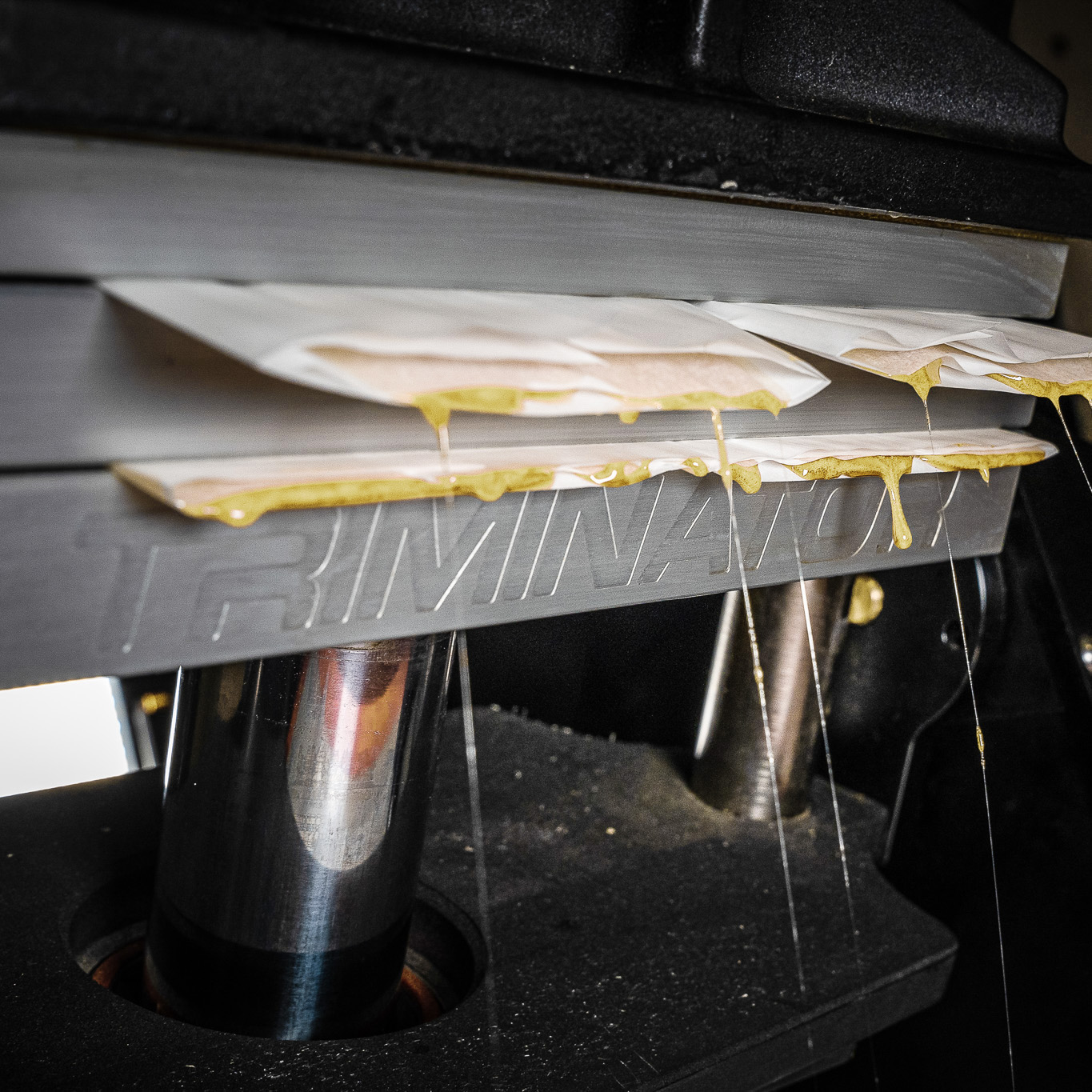

Solventless extraction for creating rosin concentrate involves pressing cannabis materials (kief, hash, or flowers) between carefully heated plates to extract rosin. The process utilizes pressure and heat to separate trichomes from the plant material.

The first step of this process is to prepare the plant material, such as creating bubble hash for hash rosin. The material is then placed in a bag between sheets of parchment paper and onto a rosin press. Depending on the input material, pre-press molds may be used to help prepare the flower or kief for pressing.

The press plates are heated to a specific temperature (typically between 160-220°F), and pressure (ranging from 300 to 2000 psi) is applied to extract the rosin.

Processing Resin

When creating resin, cultivators use solvents like butane or CO2 to dissolve terpenes and cannabinoids from plant material. Typically, cannabis is either dried and cured or flash frozen, in the case of live resin.

The plant material is then soaked in a solvent to dissolve the desired compounds, and the solvent is evaporated or purged using heat and vacuum materials. This leaves a concentrated resin behind. Further steps may then be taken to achieve specific consistencies (such as shatter or wax resin).

The Outcomes of Processing Rosin and Resin

While the results you get from rosin or resin processing will depend heavily on your cultivar and the equipment you use for the extraction process, both options can deliver an excellent yield. Rosin can deliver yields between 10-30% depending on the quality and type of the starting material. Live rosin and high-quality hash or kief will generally produce higher yields.

Resin can deliver high yield percentages of 15-30%, depending on the materials used. Live resin and BHO often deliver substantial yields, particularly when using highly potent strains.

Rosin vs Resin: Market Trends and Demand

Demand for both rosin and resin has increased significantly in recent years. Cannabis extracts are quickly emerging as one of the most popular product segments. Experts predict that by 2027, the concentrate market will be worth nearly $4 billion.

We’re also seeing an increase in the cannabis vaping market. Demand for rosin vape cartridges increased to encompass a 4% share of the vape cartridge sales in 2023.

Notably, rosin has achieved greater popularity among health-conscious consumers in recent years because of its solventless approach to extraction. Some studies even suggest that solventless products are demanding much higher prices than their counterparts as of 2023.

Additionally, there’s a growing demand for live rosin, driven by cannabis connoisseurs seeking high-quality, flavorful, and aromatic products.

High-potency products, like live resin and BHO solutions, are valued for their high cannabinoid content and exceptional impact. Plus, there’s an increasing interest in live resin due to its preserved terpene profile and enhanced flavor.

Current Market Trends

In both resin and rosin cannabis markets, there are a few key trends emerging around:

- Health and Safety: We’re seeing a growing preference for solventless products, boosting the popularity of rosin. Additionally, consumers are becoming more informed about extraction methods and potential residual solvents in resin products.

- Flavor and Potency: Consumers are prioritizing products that offer a rich terpene profile and high cannabinoid content. Live resin and live rosin are now favored for their enhanced flavor and potent effects.

- Convenience and Versatility: There’s an increasing demand for versatile consumption methods, such as vaping and dabbing. Resins, with their various consistencies and ease of use in different devices, cater well to this trend. However, rosins can be used in a variety of forms too, which allows for diversity in product portfolios.

Notably, there are some regional and global variations in market demand worth noting. For instance, in the North American market, demand for solventless extracts (including rosin), increased by 132% per month from 2021 to 2022.

Future Projections

Both the rosin and resin markets are likely to see continued growth in the years ahead. Rosin will benefit from the increasing demand for solventless products. Plus, advances in rosin press technology and accessories could lead to higher yields and lower production costs going forward.

The resin market will benefit from growing demand for high potency (live resin and BHO) products. Additionally, innovations in extraction technology may lead to enhancements in product quality and safety, which could further boost consumer demand and market confidence.

In both landscapes, changes in cannabis legislation, particularly in the US and Europe, will significantly impact market dynamics. We may see stricter regulations imposed on solvents used in extraction processes, which could help to increase demand for rosin. However, global legalization trends may also open the door to new markets for both products.

Rosin vs Resin: Profitability Analysis

The profitability of rosin vs resin can be difficult to analyze, as it depends on so many different factors. In general, rosin may command higher prices because of its purity, artisanal quality, and increasing demand for solventless solutions.

According to data from BDSA, rosin maintained its value of $35 per gram in 2022, whereas live resin sales fell to $20 per gram in the same period.

Rosin Costs and Revenue Potential

The costs associated with producing rosin often vary, as it depends on the materials and equipment being used in the process. Companies need to invest not just in the best rosin press but also in bags and accessories that are needed during the extraction.

Typically, facility setup costs are lower than they are with resin. Rosin pressing facilities can be set up in smaller spaces, but companies will still need to invest in various ongoing expenses to maintain a clean, temperature-controlled environment and access to the right tools.

Common Rosin Pressing Expenses:

- Rosin Press ($3,000-$6,000)

- Rosin Bags ($20 per pack of 10)

- Parchment paper ($35 per pack of 50)

- Flower or trim ($200-$1,300)

- Staffing (around $20 per hour, per technician)

Potential ROI

Calculating the return on investment for rosin can be complex. You have to take into account various factors such as the current price of your source material, whether that is flower, kief, trim, or bubble hash. Although profit margins for rosin production can be high, they vary depending on your processing scale and efficiency.

Resin Costs and Revenue Potential

Producing resin may incur higher initial setup costs than producing rosin. You’ll need a larger space with safety measures implemented for handling solvents. This could mean purchasing closed-loop extraction systems (which can cost up to $100,000), vacuum ovens for extraction, recovery pumps, storage tanks, and specialized CO2 extractors.

On top of that, there are various ongoing production costs to consider, including the cost of paying for skilled technicians, training them on safety measures, and maintaining extraction systems.

Resin Production Expenses:

- Closed loop extraction system ($1,500-$5,000)

- Staffing: ($25 per hour, per technician)

- Maintenance: ($100 to $300 per month)

- Recovery pumps and storage tanks: ($5,000 to $15,000)

- CO2 extractor (if using the CO2 method): ($50,000 to $150,000)

Potential ROI

Resin can command a wide range of market prices depending on the extraction method and current market demand. However, it may offer lower profit margins compared to rosin and a slower return on investment due to higher initial investment costs.

Strategies to Maximize Profitability

Whether you choose to invest in rosin, resin, or a combination of both, maximizing profitability will require a comprehensive strategy. Cultivators will need to invest in:

Optimizing Yields:

The greater the yields for your products, the more profit you’ll be able to make. To maximize rosin yield, invest in high-quality starting materials, and optimize your pressing techniques with the correct equipment, temperature, and pressure.

To enhance resin yields, use efficient solvents and recovery systems, and ensure you’re regularly maintaining your extraction equipment. Remember, high-quality and high-potency cannabis products with excellent profiles of terpenes and cannabinoids are always crucial to boosting yield. Invest in high-potency cultivars for the best rosin or resin.

Reducing Costs

The lower your operational and running costs, the greater your return on investment is likely to be for all cannabis products. Hiring the right team members with exceptional skills in rosin pressing and resin extraction should help to improve your results. Additionally, train staff for efficiency and minimize labor costs by adding automation to your business plan where possible.

Choosing the right low-cost and high-performance equipment and accessories and implementing regular maintenance schedules is crucial too. Durable equipment and regular maintenance schedules will help you avoid costly breakdowns.

Effective Market Positioning

Effective positioning and branding strategies will help attract more customers to your products and boost your chances of sales. With rosin, highlight the purity and solventless extraction process to attract health-conscious consumers. Emphasize the small-batch and artisanal nature of rosin to appeal to premium market segments and position rosin as a top-tier full-spectrum cannabinoid product.

With resin, focus on advertising the high potency of your product and the variety of forms available (live resin, wax, and shatter) to appeal to a wide audience. Advertise live resin for its aromatic profile and

showcase the range of consumption methods available.

With both products, utilize a range of marketing channels, create educational content about the benefits and characteristics of your solutions, and collaborate with experts to build credibility.

Invest in Process Optimization Techniques

Process optimization techniques will help you improve efficiency and product yield. With rosin and resin, ensure you choose high-quality, high-potency starting materials for the best results and quality. With rosin, fine-tune heat and pressure application parameters to optimize extraction efficiency, and follow GMP best practices when maintaining and cleaning equipment.

With resin, ensure you select appropriate solvents to maintain optimal extraction conditions and implement thorough purging techniques to enhance product safety. Additionally, constantly monitor and adjust extraction parameters based on batch performance to maintain high standards.

Embracing the latest high-quality technology to automate and enhance extraction processes will also help unlock more profit potential and reduce labor costs.

Remember Diversification

Remember, you don’t necessarily have to choose between resin and rosin. It’s possible to offer a range of options in both categories, catering to diverse consumer preferences and expanding your market reach. This can increase your revenue streams and reduce your dependency on a single product line. However, this method does require investment in a lot of different equipment and expertise, which can be complex for a small business to manage.

Additionally, you’ll need to invest in creating diverse marketing strategies for both products to emphasize their unique benefits and features. If you choose to offer both options:

- Establish separate production areas or schedules to avoid cross-contamination and streamline workflows.

- Train staff on the distinct processes and quality standards for each product type.

- Implement robust inventory management systems to track raw materials and finished products effectively.

- Create targeted marketing campaigns for each product line, emphasizing their unique benefits and features.

- Use data analytics to understand consumer preferences and tailor marketing efforts accordingly.

- Offer bundled deals or cross-promotions to encourage customers to try both rosin and resin products.

Rosin vs Resin: Which is Right for You?

Rosin and resin are two extremely profitable product categories for cannabis cultivators to explore. They both allow you to take advantage of the growing demand for cannabis extracts in the current market. However, each option requires a specific approach to purchasing equipment, managing extraction, and promoting your unique offering.

Ultimately, rosin may be the best option for companies with a limited budget for initial equipment and production costs. It could also allow you to leverage the growing demand for solventless products in the cannabis market.

Resin, on the other hand, gives cannabis cultivators more reach and opportunities to connect with a wide range of customers, but it can be expensive to create initially.

Whichever option you choose, the right equipment will be crucial to your success. Contact the Triminator team today to see how we can help to optimize your production processes, increase your revenue, and expand into new markets.

Like what you read?

Get more insider industry knowledge sent right to your inbox

"*" indicates required fields